Split-winding transformer

A technology for splitting transformers and high-voltage windings, applied in transformer/inductor cores, transformer/inductor coils/windings/connections, etc., can solve problems such as poor short-circuit resistance, and achieve improved split impedance, simple structure, and short-circuit impedance increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

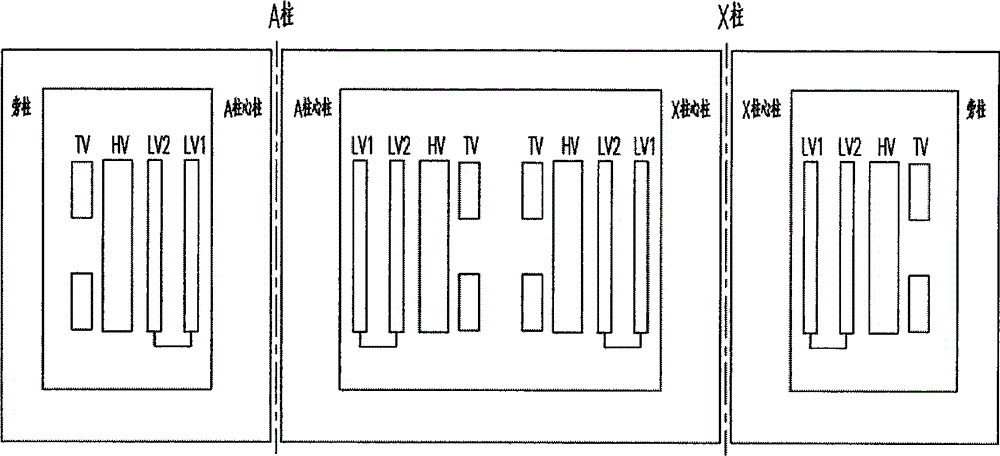

[0037] The split transformer in this embodiment is a single-phase split transformer, specifically, a single-phase two-column parallel-connected double-split transformer. In this embodiment, the split transformer is applied to an ultra-high voltage large-scale transformer of a hydropower station subject to transportation restrictions. In this embodiment, it can be specifically applied to a transformer with a voltage level of 400 kV or 500 kV and above. Together with two generators, it forms a two-machine-one-change split transformer, that is, the low-voltage side of the primary side can be connected to two generators, and the high-voltage side of the secondary side is only led out by one way, so as to increase the voltage of the generator Connect to the grid again. In this embodiment, the capacity of the split transformer is specifically 147MVA.

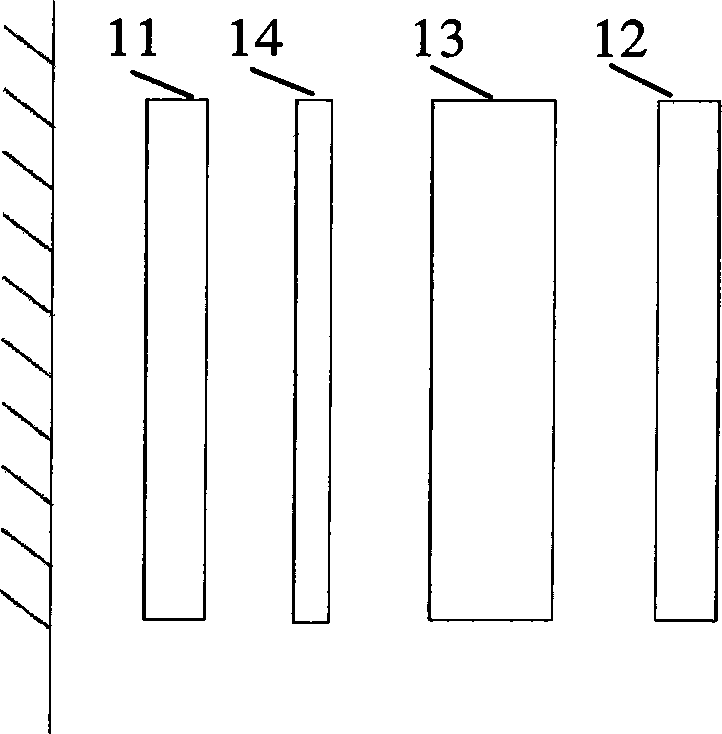

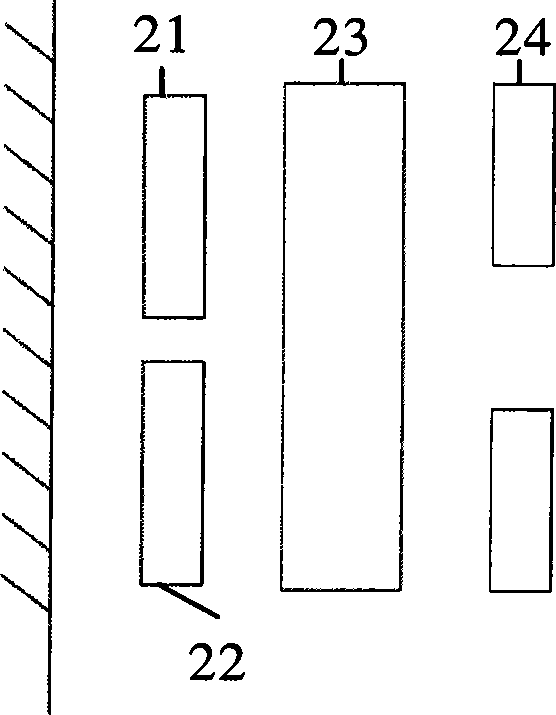

[0038] Such as image 3 As shown, the split transformer in this embodiment includes an iron core and a winding, and the winding in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com