Direct characteristic control based novel double-fed induction motor control method

A doubly-fed induction motor and characteristic control technology, which is applied in the direction of control of generators, motor generators, electromechanical brakes, etc., can solve problems such as difficult parameter adjustment, achieve fast current response, suppress torque harmonics, and facilitate correctness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and examples.

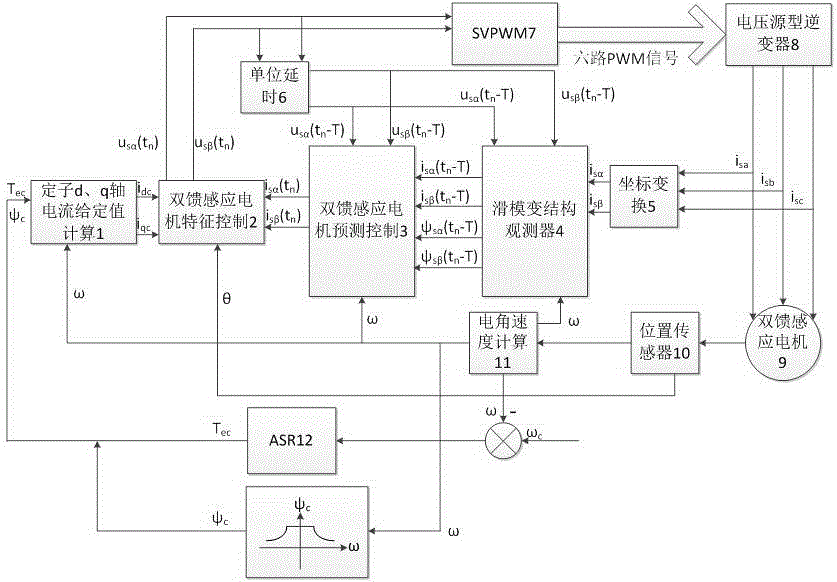

[0023] figure 1 It is a block diagram of the overall structure of the doubly-fed induction motor control system based on characteristic control. The system includes stator d and q-axis current given value calculation 1, doubly-fed induction motor characteristic control 2, doubly-fed induction motor predictive control 3, sliding mode variable structure Observer 4, coordinate transformation 5, unit delay module 6, SVPWM module 7, voltage source inverter 8, double-fed induction motor 9, position sensor 10, electrical angular velocity calculation module 11, speed regulator ASR module 12.

[0024] The input end of the position sensor 10 is drawn out from the output end of the double-fed induction motor 9 , and the input end of the electrical angular velocity calculation module 11 is drawn out from the output end of the position sensor 10 . The coordinate transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com