Spray nozzle for fluidized catalytic cracking

A technology of spray nozzles and nozzles, which is applied in the field of spray nozzle components, and can solve problems such as erosion, increased cost of nozzle components, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

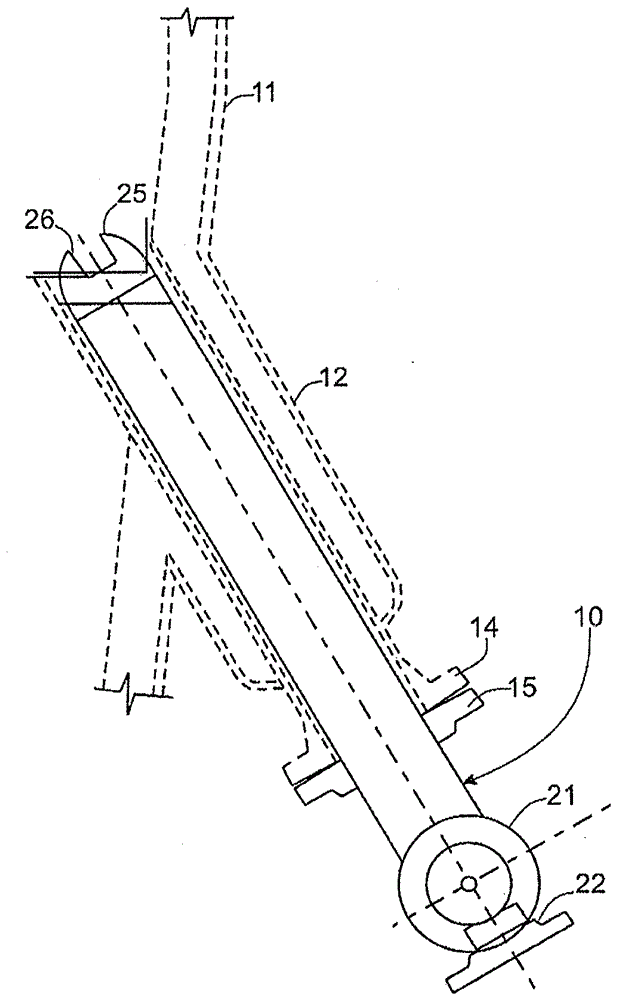

[0012] Referring now more specifically to the drawings, there is shown an exemplary spray nozzle assembly 10 according to the present invention mounted in a conventional manner within an insulating wall 11 (shown in phantom) of a riser of a fluidized catalytic reactor. The spray nozzle assembly 10 is supported within a tubular sleeve 12 secured within the wall 11 at an acute angle to the vertical to discharge atomized liquid hydrocarbons upward into the standpipe. The tubular sleeve 12 has an outwardly extending flange 14 to which a support flange 15 secured to the spray nozzle assembly 10 may be secured.

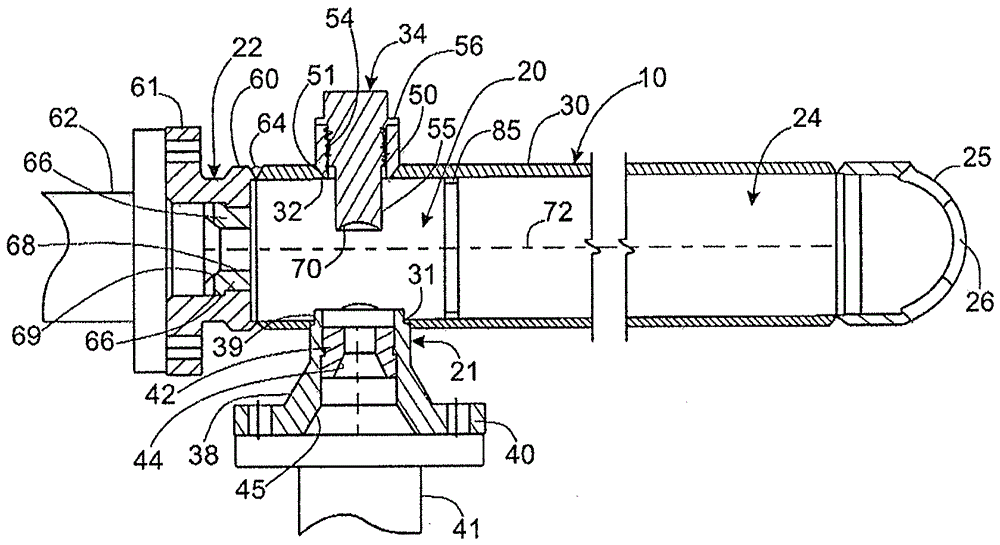

[0013] as in figure 2 As best shown in , the spray nozzle assembly 10 basically includes a mixing zone 20 , an elongated barrel extension 24 communicating with the mixing zone 20 , and a nozzle tip 25 having one or more discharge orifices 26 . The mixing zone 20 has a liquid hydrocarbon inlet 21 and a pressurized steam or gas inlet 22 provided on the outside of the riser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com