Surface-treated metal powder, and method for producing same

A technology of surface treatment and manufacturing method, which is applied in the direction of metal processing equipment, cable/conductor manufacturing, fixed capacitor parts, etc., and can solve the problems of long mixing time and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

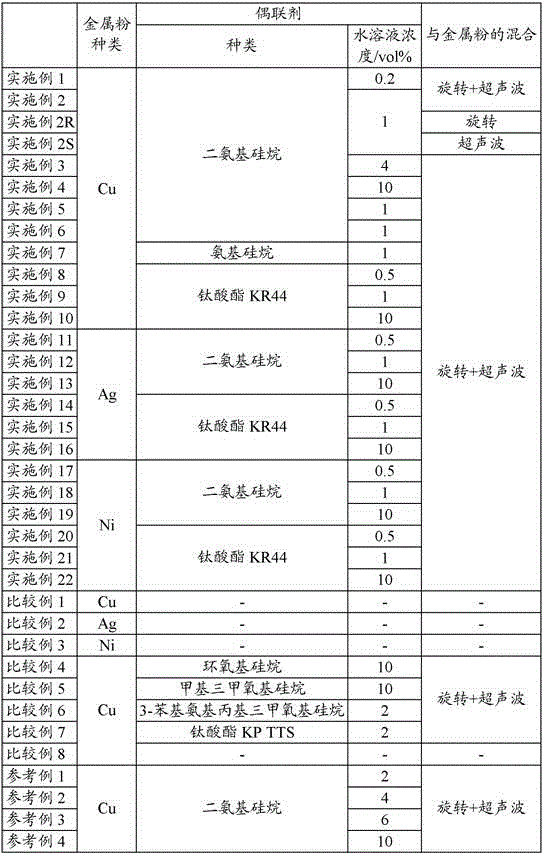

[0191] Hereinafter, examples are given to describe the present invention in further detail. However, the present invention is not limited by the following examples.

[0192] [metal powder]

[0193] As the metal powder, copper powder, nickel powder, and silver powder were prepared in the following order.

[0194] (copper powder produced by the disproportionation method (used in addition to Example 6))

[0195] 20 g of copper powder for surface treatment was produced by the above-mentioned wet method using the disproportionation method. Specifically, it was carried out in the following order.

[0196] (1) Add 50 g of cuprous oxide to 0.05 to 0.4 g of gum arabic + 350 mL of pure water.

[0197] (2) Next, 50 mL of 25 wt % dilute sulfuric acid was temporarily added.

[0198] (3) This was left to stand for 60 minutes after being stirred with a rotating paddle (300 rpm×10 minutes).

[0199] (4) Next, the precipitate is washed.

[0200] When cleaning, first remove the supernata...

Embodiment 5

[0265] In order to confirm that the sintering retardation property of the present invention is maintained even if the surface-treated copper powder obtained in the above-mentioned Example 2 is further subjected to antirust treatment, the following experiment (Example 5) was performed.

[0266] After the surface-treated copper powder was obtained in Example 2, it was dispersed in 100 mL of 0.1 g / L benzotriazole aqueous solution in order to perform antirust treatment with an organic compound, stirred at 500 rpm for 10 minutes with a rotating paddle, and filtered , drying (70 ℃ * 1 hour under nitrogen environment), and then obtained the copper powder (embodiment 5) through antirust treatment. The antirust-treated copper powder was evaluated in accordance with the procedure of Example 2. It should be noted that the metal powders treated with antirust were evaluated, and the results are summarized in Tables 1 to 3. The size of the metal powders "after treatment" in Table 2 refers t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com