Regional superheated steam textile fabric drying and setting machine and combination thereof

A superheated steam, textile fabric technology, applied in liquid/gas/steam textile material processing, textile material processing, textile and papermaking, etc., can solve the problem of insignificant energy saving effect, avoid heat loss, full contact, distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

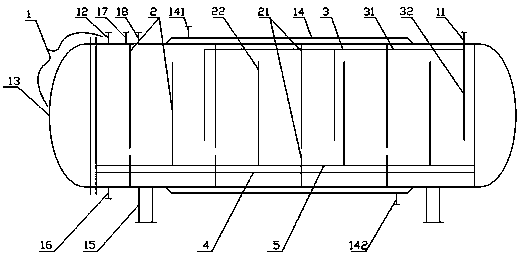

[0031] The specific embodiment of the present invention sees Figure 1-10 :

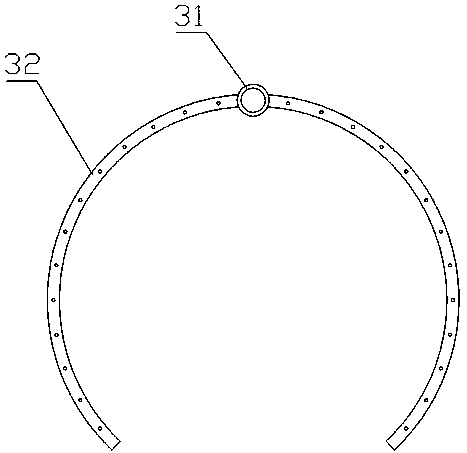

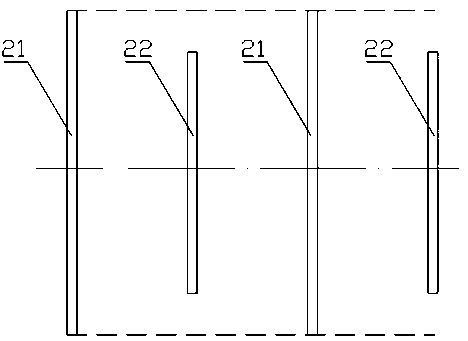

[0032] A sub-area superheated steam textile cloth drying and setting machine, such as figure 1 , comprising a cylindrical structure box 1 and a support saddle 15 positioned below the box body 1, one end of the box body 1 is provided with an upper superheated steam inlet 11, and the other end of the box body 1 is an oval The cloth inlet and outlet 13 of the shaped cover, the top of the box body 1 is also provided with a steam outlet 12 close to the cloth inlet and outlet 13, and the inside of the box body 1 is provided with a steam outlet located at the top and connected to the superheated steam inlet 11 A connected rib-type superheated steam distributor 3, the bottom of the box body 1 is provided with two parallel and axially arranged guide rails 4, the inside of the box body 1 is provided with a cloth inlet and outlet 13 and The distribution vehicle 5 moving on the guide rail 4, the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com