Glass melting furnace and glass melting method

A technology of glass melting furnace and glass melting furnace, which is applied in the direction of glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc. It can solve the problems of refractory material erosion or condensate dripping, volatile glass, and obvious problems, so as to reduce maintenance Effects of cost, extended service life, and strong structural flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

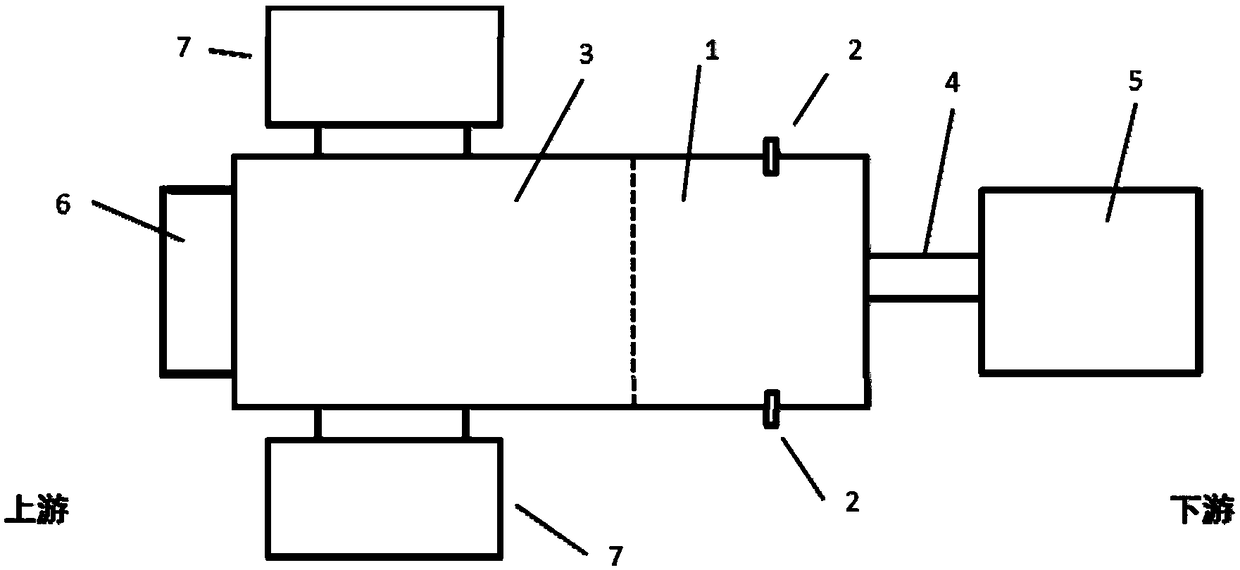

[0062] The schematic diagram of the top view structure of the glass melting furnace used in this embodiment is as follows figure 1 As shown, the glass melting furnace includes: a clarifying part 1 , a spray gun 2 , a melting part 3 , a flow hole 4 , a cooling part 5 , a feed port 6 and a heat accumulator 7 . The melting part 3, the clarification part 1, the liquid flow hole 4 and the cooling part 5 are connected in sequence, the clarification part 1 and the melting part 3 are integrated into one space, and the side where the clarification part 1 is connected with the liquid flow hole 4 is provided with a rear gable to clarify There are breast walls on both sides of part 1.

[0063] Two spray guns 2 are symmetrically arranged on both sides of the parapet wall of the clarification part 1. The distance of the spray gun 2 above the glass liquid is 0.6m. All are air spray guns, and the nozzle materials are all refractory materials. The nozzles of the two spray guns 2 are all alig...

Embodiment 2

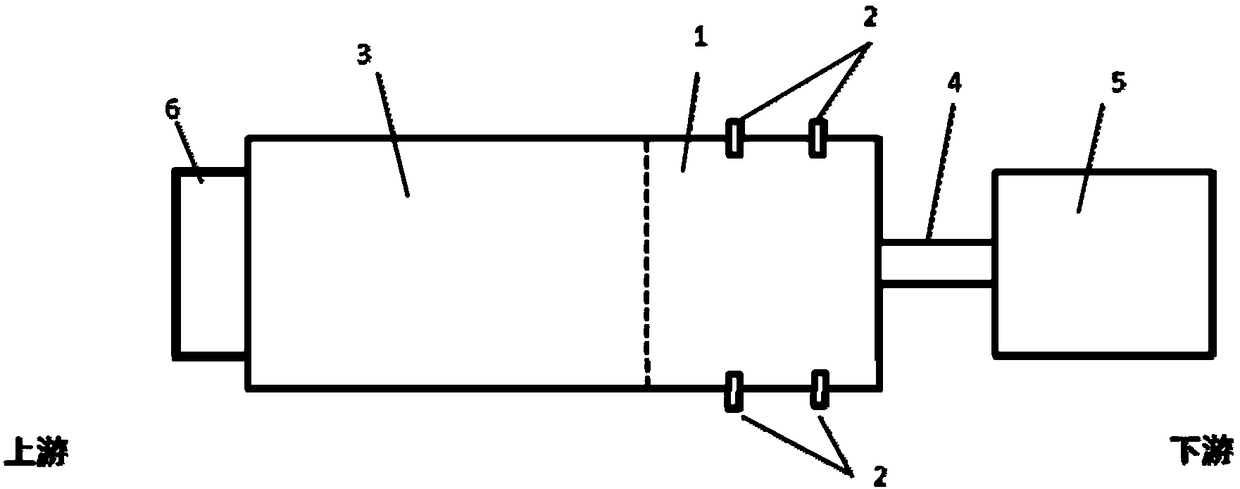

[0070] The schematic diagram of the top view structure of the glass melting furnace used in this embodiment is as follows figure 2 As shown, the glass melting furnace includes: a clarifying part 1 , a spray gun 2 , a melting part 3 , a flow hole 4 , a cooling part 5 and a feed port 6 . The melting part 3, the clarification part 1, the liquid flow hole 4 and the cooling part 5 are connected in sequence, the clarification part 1 and the melting part 3 are integrated into one space, and the side where the clarification part 1 is connected with the liquid flow hole 4 is provided with a rear gable to clarify There are breast walls on both sides of part 1.

[0071] Four spray guns 2 are symmetrically arranged in pairs on both parapet walls of the clarification unit 1. The distance of the spray guns 2 above the molten glass is 1m, and the installation position of the spray gun 2 nearest to the gable wall of the clarification unit 1 is at the level of the gable wall of the clarificat...

Embodiment 3

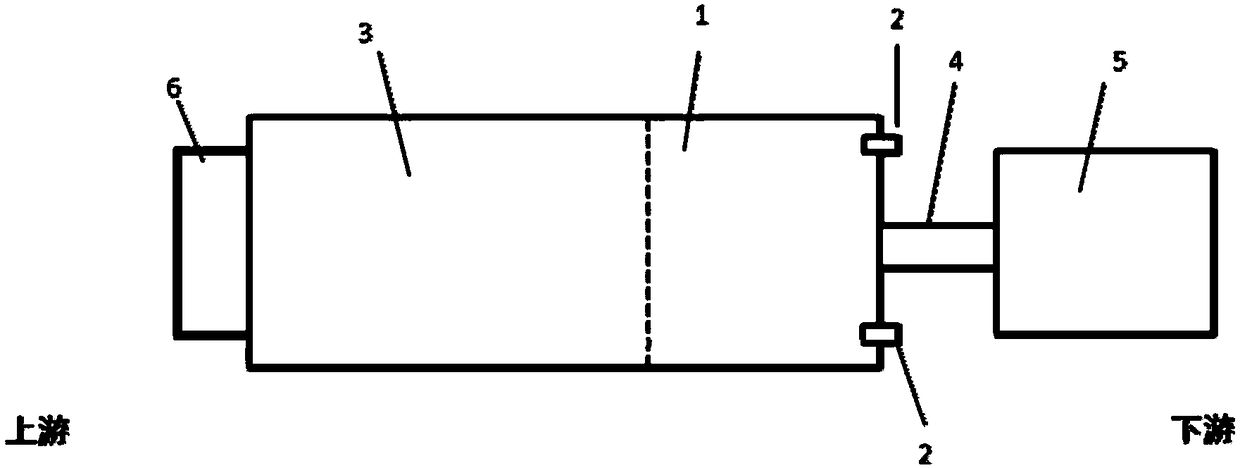

[0078] The schematic diagram of the top view structure of the glass melting furnace used in this embodiment is as follows image 3 As shown, the glass melting furnace includes: a clarifying part 1 , a spray gun 2 , a melting part 3 , a flow hole 4 , a cooling part 5 and a feed port 6 . The melting part 3, the clarification part 1, the liquid flow hole 4 and the cooling part 5 are connected in sequence, the clarification part 1 and the melting part 3 are integrated into one space, and the side where the clarification part 1 is connected with the liquid flow hole 4 is provided with a rear gable to clarify There are breast walls on both sides of part 1.

[0079] Two spray guns 2 are arranged in pairs on the back gable wall of the clarification part 1. The distance of the spray guns 2 above the molten glass is 1m. The two spray guns 2 are all oxygen spray guns, and the nozzle materials are all refractory materials. The spray nozzles of the two spray guns 2 are all retracted in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com