Single-body profiling two-row mung bean seeder

A kind of seeder, a single technology, applied in the direction of seeder parts, fertilizers and seeding equipment, planting methods, etc., can solve the problems of difficult precise control of fertilizer application and seeding amount, inability to realize double-row sowing in large ridges, and poor maneuverability , to achieve the effect of compact structure of the transmission mechanism, compact and reasonable design structure, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

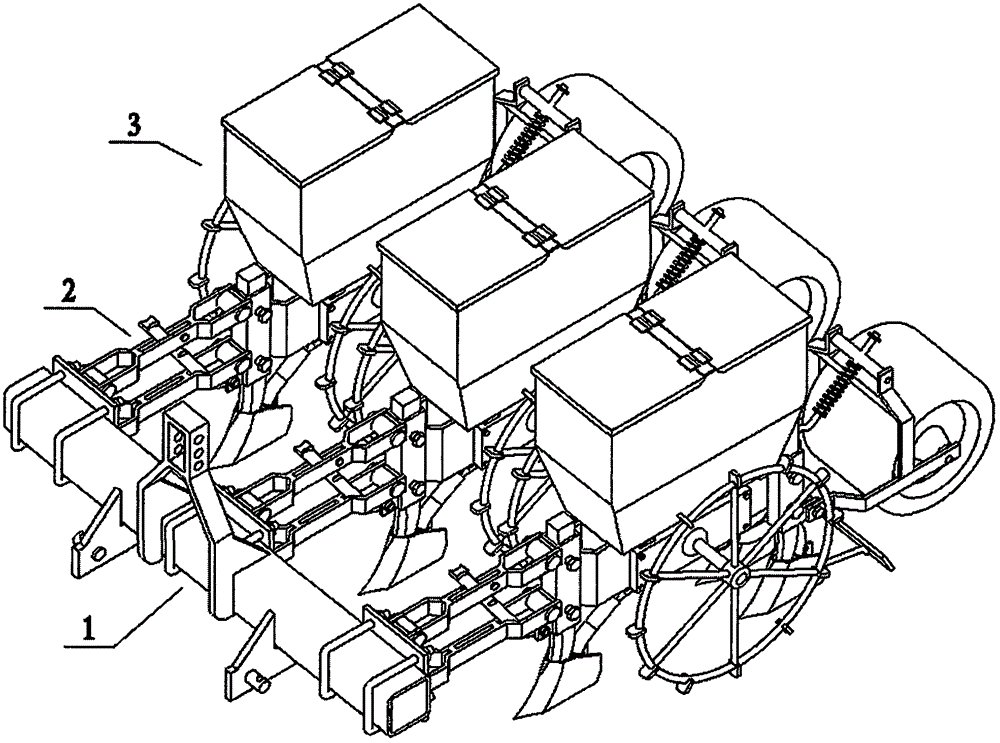

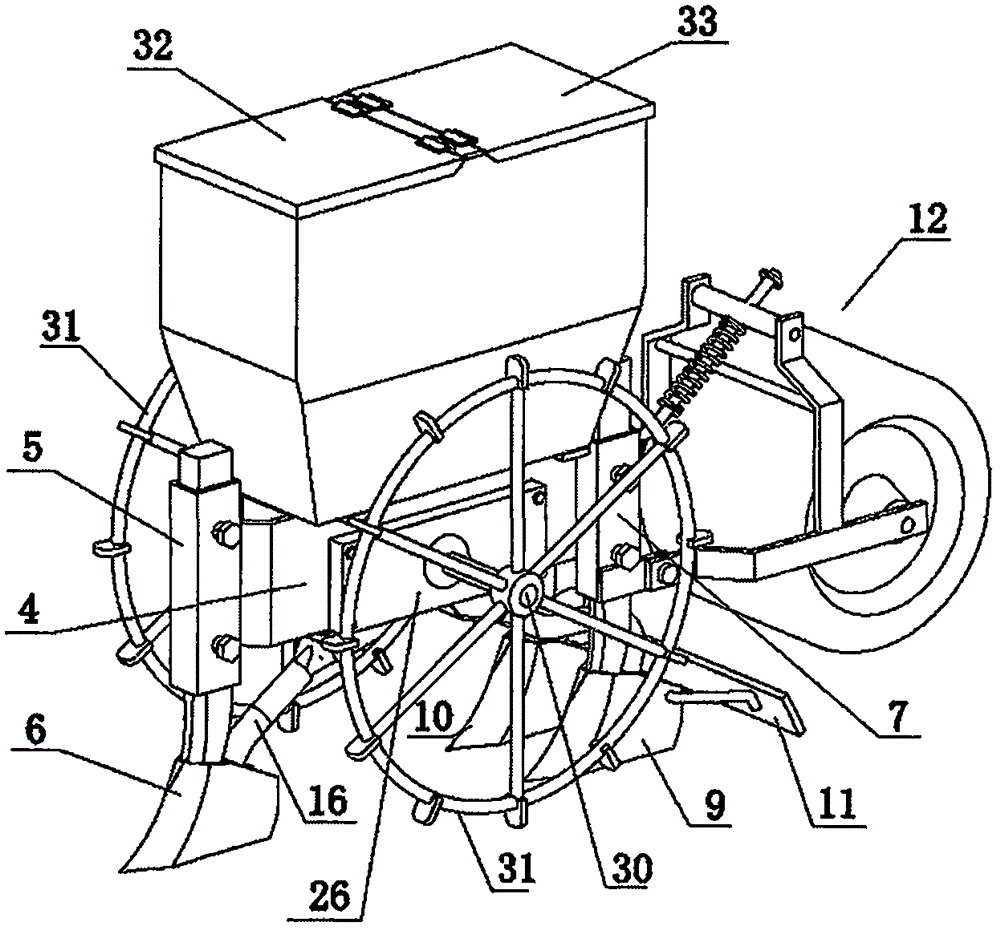

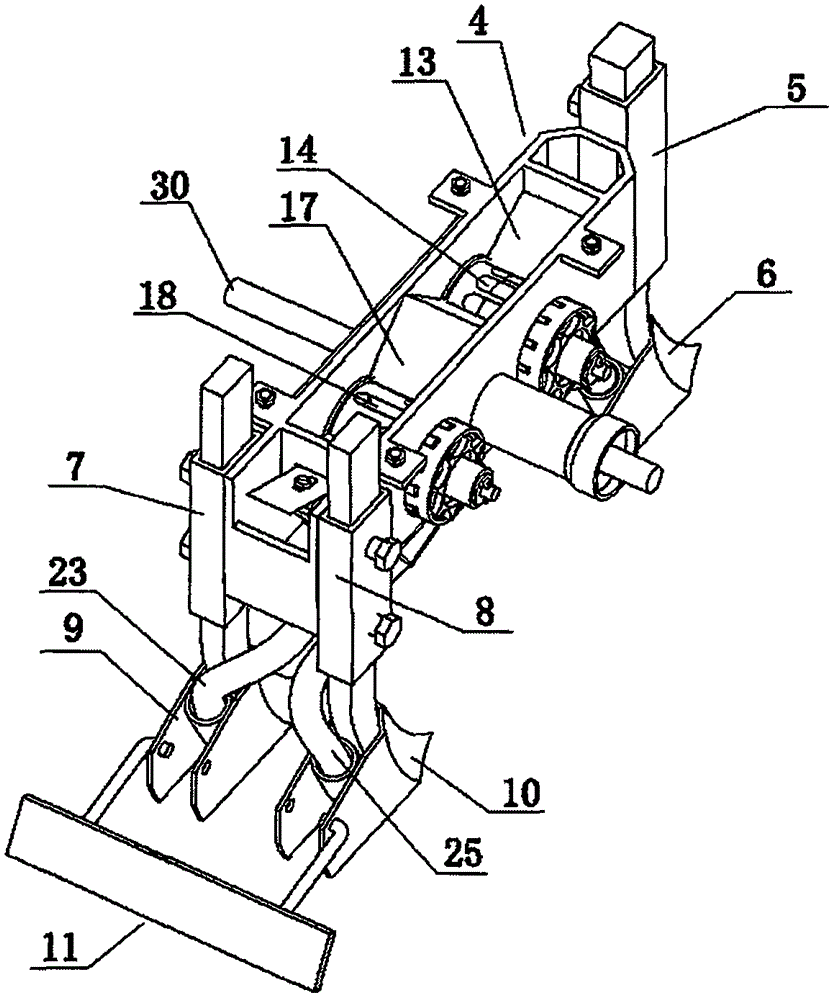

[0024] Example 1: see Figure 1 to Figure 7 Shown, a kind of monomer profiling two-row mung bean planter, it comprises suspension frame 1, connects a plurality of monomer fertilizing seeders 3 by profiling connection device 2 at the crossbeam rear side of suspension frame 1, described monomer The fertilizing seeder 3 includes a housing 4, the front end of the housing 4 is provided with a front plow column sleeve 5, the fertilization furrowing plow 6 is installed in the front plow column sleeve 5, and the rear left plow column sleeve 7 is provided at the rear of the housing 4. And rear right plow post sleeve 8, install left sowing ditch plow 9 in back left plow post sleeve 7, install right sow ditch plow 10 in back right plow post sleeve 8; The rear of the sowing furrowing plow 10 is connected to the soil cover 11; the rear of the soil cover 11 is provided with an elastic suppressor 12 connected to the rear of the housing 4; Set the fertilizer discharge sheave 14, the lower pa...

Embodiment 2

[0025] Example 2: see Figure 8 As shown, other structures are the same as the embodiment, except that the described double row seed hole wheel 18 is a double row seed hole wheel with fixed seed holes, and it is provided with two circles of seed holes 34 annularly on the cylindrical roller, each Circle is 6 kinds of holes 34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com