Lactobacillus fermentation vegetable protein beverage and manufacturing method thereof

A plant protein beverage and lactic acid bacteria fermentation technology, applied in the field of plant protein beverages, can solve problems such as unacceptable odor, and achieve the effect of solving unacceptable taste and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

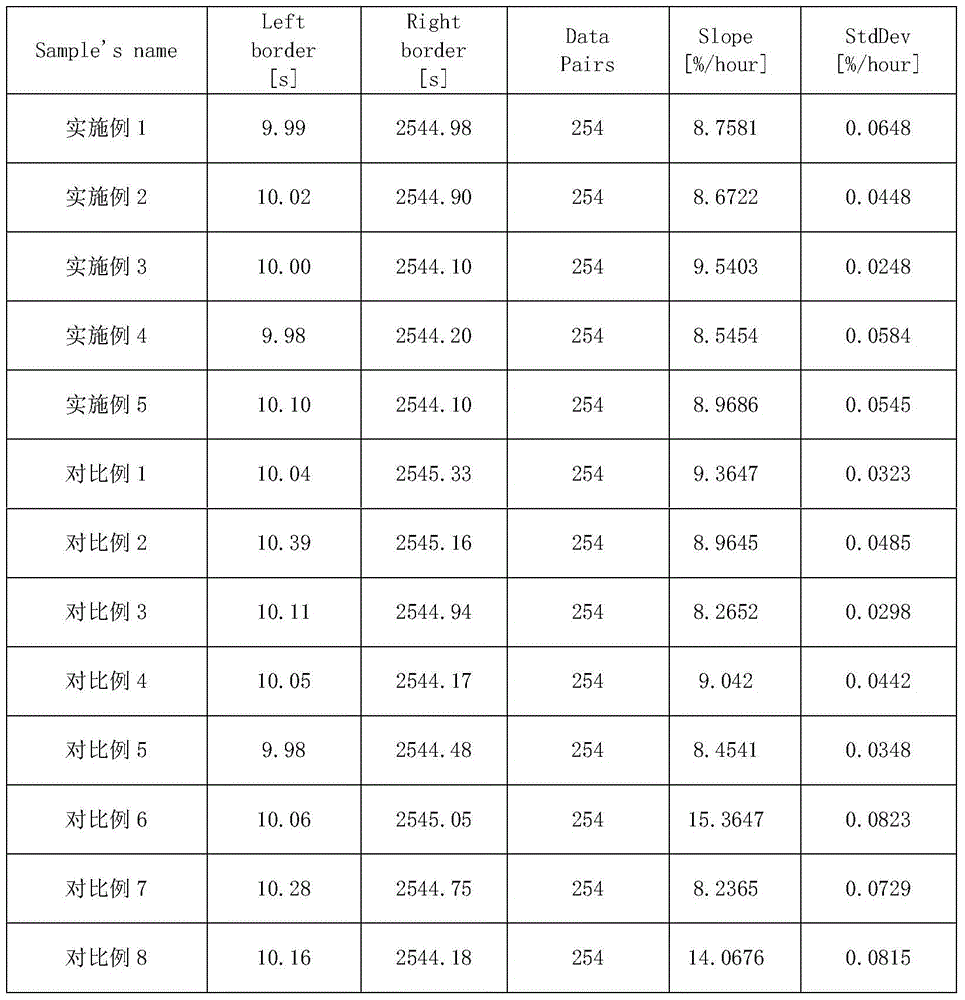

Examples

no. 1 example

[0029] A method for preparing a lactic acid bacteria fermented vegetable protein beverage, comprising:

[0030] Step 1, preparation of fermentation base material

[0031] Among them: instant soybean powder 7.0%, anhydrous dextrose 3.0%, walnut powder 2.0%, water to make up to 100%;

[0032] (1), ingredients

[0033] Raise the temperature of the ingredients with water to 40°C and the stirring speed is 2500r / min, add instant soybean powder, other vegetable protein powder, and glucose, and keep stirring for 5 minutes.

[0034] (2), homogeneous:

[0035] Homogenization was performed at 20°C with a pressure of 160 bar.

[0036] (3), hydration:

[0037] Raise the temperature of the feed solution to 60°C, stop stirring, and let stand for 30 minutes.

[0038] (4), Browning:

[0039] Raise the temperature of the feed liquid to 94°C and keep it for 1.5 hours, and determine the end point of browning by judging the color of the feed liquid.

[0040] (5), fermentation:

[0041] Aft...

no. 2 example

[0060] A method for preparing a lactic acid bacteria fermented vegetable protein beverage, comprising:

[0061] Step 1, preparation of fermentation base material

[0062] Instant soybean powder 15.0%, anhydrous dextrose 7.0%, almond flour 2.0%, water to 100%,

[0063] (1), ingredients

[0064] Raise the temperature of ingredients with water to 45°C and stir at 4000r / min, add instant soybean powder, almond powder, and glucose, and keep stirring for 5 minutes.

[0065] (2), homogeneous:

[0066] Homogenize the feed solution at 65°C with a pressure of 400 bar.

[0067] (3), hydration:

[0068] Raise the temperature of the feed solution to 65°C, stop stirring, and let it stand for 60 minutes.

[0069] (4), Browning:

[0070] Raise the temperature of the feed liquid to 97°C and keep it for 3 hours, and determine the end point of browning by judging the color of the feed liquid.

[0071] (5), fermentation:

[0072] After the browning is completed, the feed liquid is cooled to ...

no. 3 example

[0092] A method for preparing a lactic acid bacteria fermented vegetable protein beverage, comprising:

[0093] Instant soybean powder 10.0%, anhydrous glucose, 5.0%, almond powder 1.0%, hazelnut powder 0.5%, walnut powder 0.2%, almond powder 0.3%, water to 100%,

[0094] Step 1, preparation of fermentation base material

[0095] (1), ingredients

[0096] Raise the temperature of ingredients with water to 44°C and the stirring speed is 3500r / min, add instant soybean powder, almond powder, and glucose, and keep stirring for 5 minutes.

[0097] (2), homogeneous:

[0098] Homogenize the feed solution at 55°C with a pressure of 280 bar.

[0099] (3), hydration:

[0100] Raise the temperature of the feed solution to 64°C, stop stirring, and let stand for 40 minutes.

[0101] (4), Browning:

[0102] Raise the temperature of the feed liquid to 96°C and keep it for 2.5 hours, and determine the end point of browning by judging the color of the feed liquid.

[0103] (5), fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com