Formaldehyde catching agent, preparation method thereof and application thereof in formaldehyde removal

A formaldehyde scavenger, methyl technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., to achieve the effect of low production cost, high formaldehyde elimination efficiency, and high affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

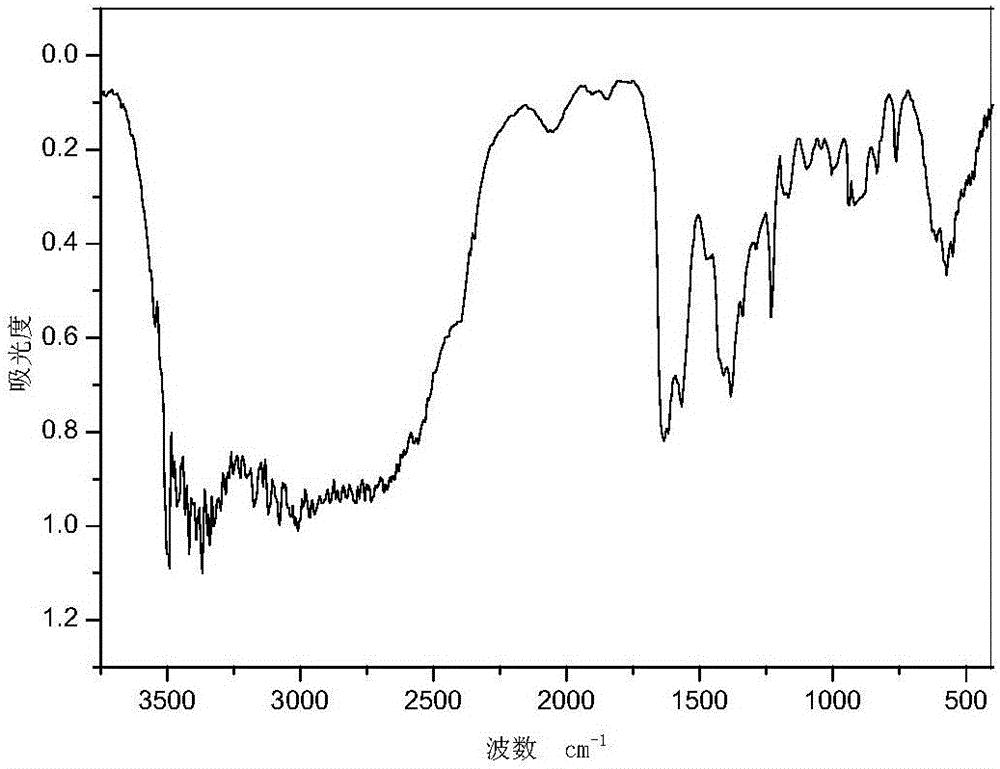

Embodiment 1

[0068] The amount of each raw material used in the preparation of the formaldehyde scavenger in this embodiment is as shown in Table 1, Example 1.

[0069] 1. Preparation of formaldehyde scavenger

[0070] Add various raw materials in the feeding stage to the reactor, the pH value is 4, and the temperature is raised to 85°C. After all the raw materials are completely dissolved, 10wt% ammonium persulfate aqueous solution is started to be added dropwise, and the temperature is maintained at 85-90°C during this process. After hours of dripping, continue to incubate at 90° C. for 4 hours. After the heat preservation is completed, cool down to 0-5°C with ice water, add the required sodium hypochlorite and sodium hydroxide, and react for 5 hours to obtain the formaldehyde scavenger.

[0071] The formaldehyde scavenger prepared in this example is a cross-linked polymer, and its structural units are shown in formula I, formula II, formula III and formula IV,

[0072]

[0073] In ...

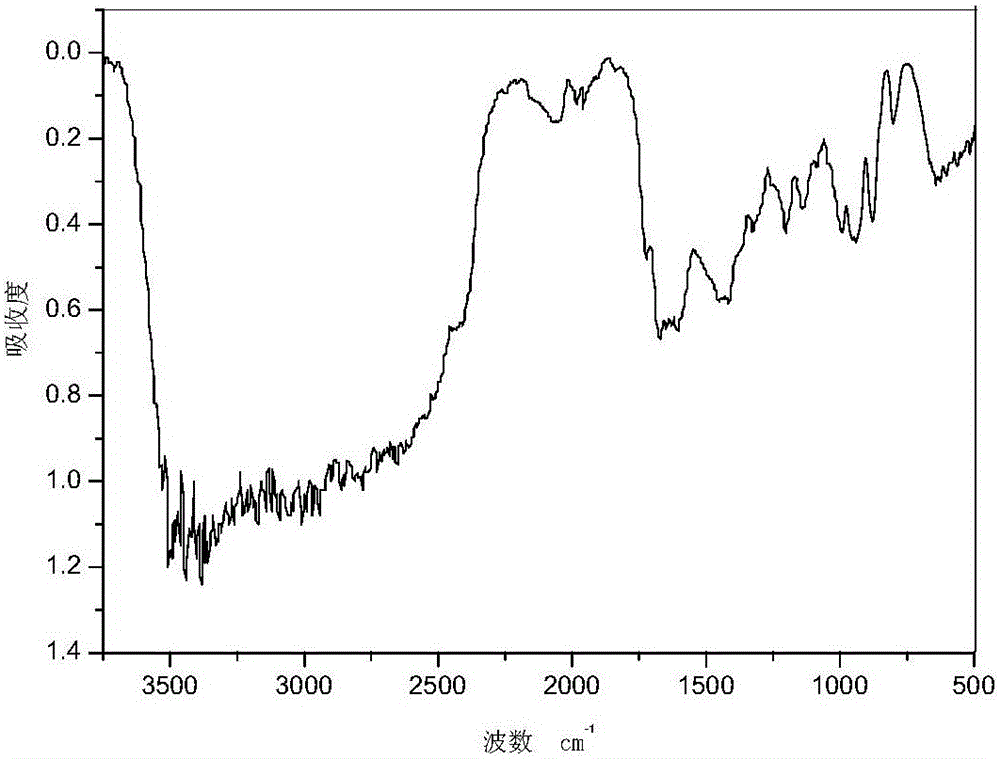

Embodiment 2

[0082] The amount of each raw material used in the preparation of the formaldehyde scavenger in this embodiment is as shown in Table 1, Example 2.

[0083] 1. Preparation of formaldehyde scavenger

[0084] Add various raw materials in the feeding stage to the reactor, the pH value is 4, and the temperature is raised to 75°C. After all the raw materials are completely dissolved, 20wt% ammonium persulfate aqueous solution is started to be added dropwise, and the temperature is maintained at 75-80°C during this process. After 1 hour of dripping, continue to incubate at 80° C. for 4 hours. After the heat preservation is completed, cool down to 5-10°C with ice water, add the required sodium hypochlorite and sodium hydroxide, and react for 6 hours to obtain the formaldehyde scavenger.

[0085] The formaldehyde scavenger prepared in this example is a cross-linked polymer, and its structural units are shown in formula I, formula II, formula III and formula IV,

[0086]

[0087] I...

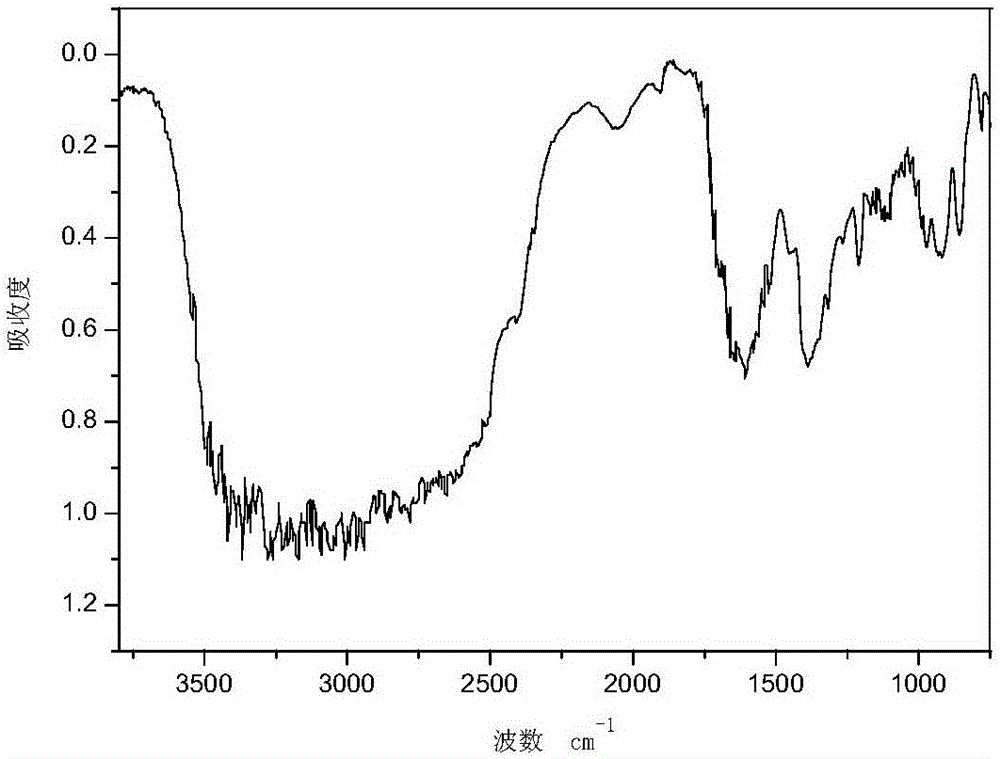

Embodiment 3

[0096] The amount of each raw material used in the preparation of the formaldehyde scavenger in this embodiment is as shown in Table 1, Example 3.

[0097] 1. Preparation of formaldehyde scavenger

[0098] Add various raw materials in the feeding stage to the reactor, the pH value is 4.5, and the temperature is raised to 65°C. After all the raw materials are completely dissolved, 30wt% ammonium persulfate aqueous solution is started to be added dropwise. During this process, the temperature is kept at 65-70°C. After 1 hour of dripping, continue to incubate at 70° C. for 5 hours. After the heat preservation is completed, cool down to 5-10°C with ice water, add the required sodium hypochlorite and sodium hydroxide, and react for 8 hours to obtain the formaldehyde scavenger.

[0099] The formaldehyde scavenger prepared in this example is a cross-linked polymer, and its structural units are shown in formula I, formula II, formula III and formula IV,

[0100]

[0101] In formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com