High-quality sand crushing production technique

A production process and high-quality technology, applied in the direction of grain processing, etc., can solve the problems of limited varieties of sand and gravel, uneven particle size, and excessive dust content, and achieve high-quality, high-yield, and high-quality effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

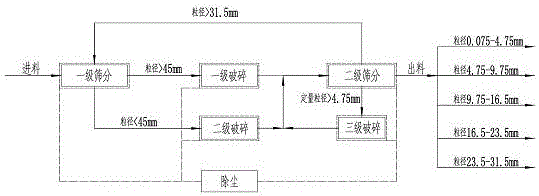

[0016] Such as figure 2 As shown, the high-efficiency and high-quality sand and gravel crushing production process of the present invention, the steps are: first, the sand and gravel materials are subjected to primary screening and divided into different particle sizes, and then sent to the impact crusher for primary crushing and sent to the impact crusher. The impact crusher performs secondary crushing, and then performs secondary screening on the materials to produce several kinds of product materials. Among them, the product materials exceeding the particle size requirements are returned to the upper level for crushing and rework, or the quantitative product materials meeting the required particle size are sent to the into the sand making machine for three-stage crushing to increase the output of fine sand.

[0017] Among them: primary screening: u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com