Bulk material conveying system, mobile single-roll crusher and control method and system of mobile single-roll crusher

A single-roller crusher and control method technology, applied to conveyors, chemical instruments and methods, grain processing, etc., can solve the problems of materials that cannot be crushed, broken kinetic energy of the crushing roller, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 example

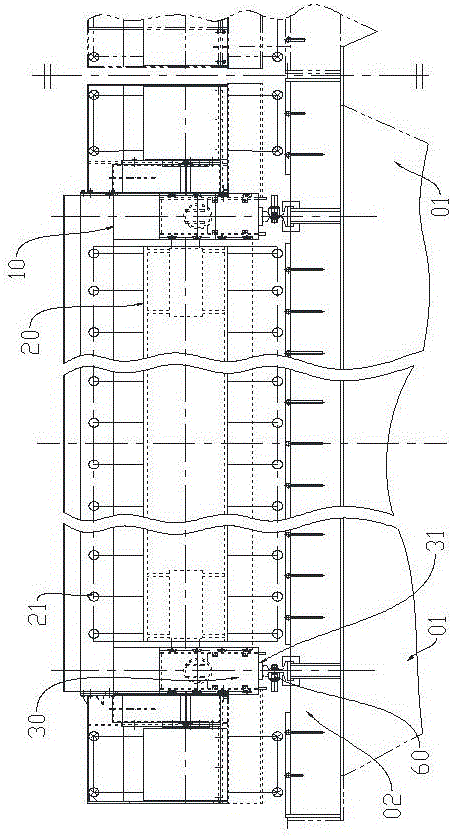

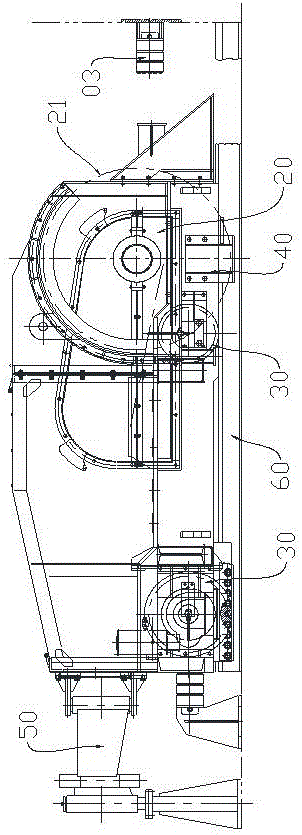

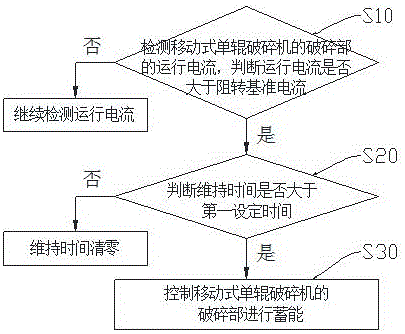

[0147] As mentioned above, the present invention can also use the running current of the running part as a reference. Such as figure 1 , 2 As shown in and 9, the fifth embodiment of the control method of the mobile single roll crusher provided by the present invention includes the following specific steps.

[0148] Step S210: Detect the operating current of the traveling part of the mobile single-roller crusher, and determine whether the operating current is greater than the reference current for stalling, if yes, count the maintenance time; if not, continue to detect the operating current of the traveling part.

[0149] Step S220, judging whether the maintenance time is greater than the first set time, if yes, execute step S230; if not, clear the maintenance time. The first set time is generally 1-5 seconds, preferably 2-4 seconds, more preferably 2-3 seconds.

[0150] Step S230, controlling the crushing part of the mobile single-roll crusher to store energy. Optional ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com