Multichannel online eliminating conveying belt

A conveyor belt and multi-channel technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of actual processing difficulties, manpower consumption, low efficiency, etc., to reduce manual finishing, reduce intermediate links, and weight accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

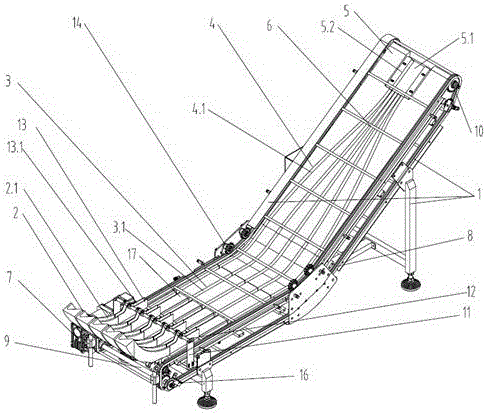

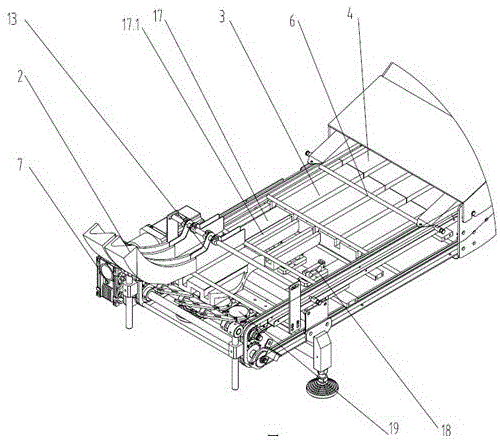

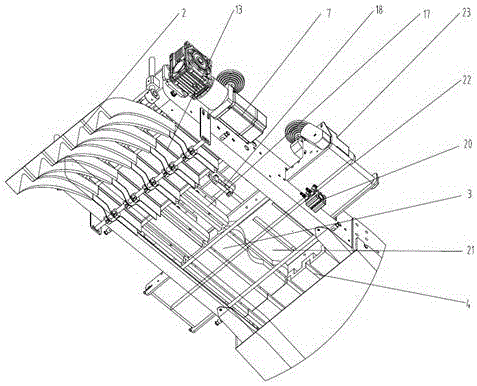

[0028] Such asfigure 1 , figure 2 , image 3 with Figure 4 As shown, the multi-channel on-line rejecting conveyor belt of the present invention includes a frame 1, an adjustable guide block 2 for entering multi-row packaging machine products, a chute guide rail 3, a curved chute guide rail 4, a product output adjustment block 5, A plurality of transmission scrapers 6 and a drive mechanism that drives the transmission scrapers 6; the height of the discharge end of the frame 1 is greater than the height of the feed end, and the adjustable guide block 2, chute guide rail 3, and curved chute guide rail 4 , The product output adjustment block 5 is arranged on the frame 1 in turn, the adjustable guide block 2 is located at the feed end of the frame 1, the product output adjustment block 5 is located at the discharge end of the frame 1, and the adjustable The guide block 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com