Winding device for active optical fiber and fiber winding method

An optical fiber and winding technology, which is applied in the field of high-power fiber lasers or fiber amplifiers, can solve the problems that a certain compressive stress is easily generated at the fixed place, affects the uniformity of fiber heat dissipation, and affects the stability of output light, so as to reduce the difference in winding diameter. , maintain natural stretch, optimize the effect of output beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0017] like Figure 1~3 As shown, a coiling device for active optical fiber, it includes a body, the body has:

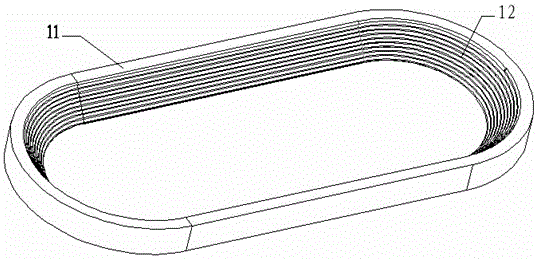

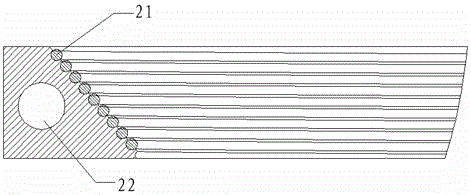

[0018] The heat dissipation disk 11, the heat dissipation disk 11 is a racetrack structure, and the inner wall surface of the heat dissipation disk 11 is a slope, and the inner wall slope of the heat dissipation disk 11 is provided with a container for attaching the optical fiber 21 to the heat dissipation disk 11. There is a space between adjacent turns of the optical fiber 21 on the housing structure.

[0019] like Figure 1~3 As shown, the accommodating structure is a semicircular groove 12 arranged on the inclined surface of the inner wall and coiled from bottom to top, and the diameter of the semicircular groove 12 and the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com