Double-cladding all-solid photonic crystal gain fiber and manufacturing method thereof

A photonic crystal fiber, all-solid-state technology, applied in cladding fiber, multi-layer core/cladding fiber, glass manufacturing equipment, etc., can solve the limitation of single-mode all-solid-state photonic crystal fiber High, did not achieve large mode field single-mode output and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned double-clad all-solid-state photonic crystal fiber is characterized in that it comprises the following steps:

[0026] ① Preparation of glass rods with uniform outer diameter:

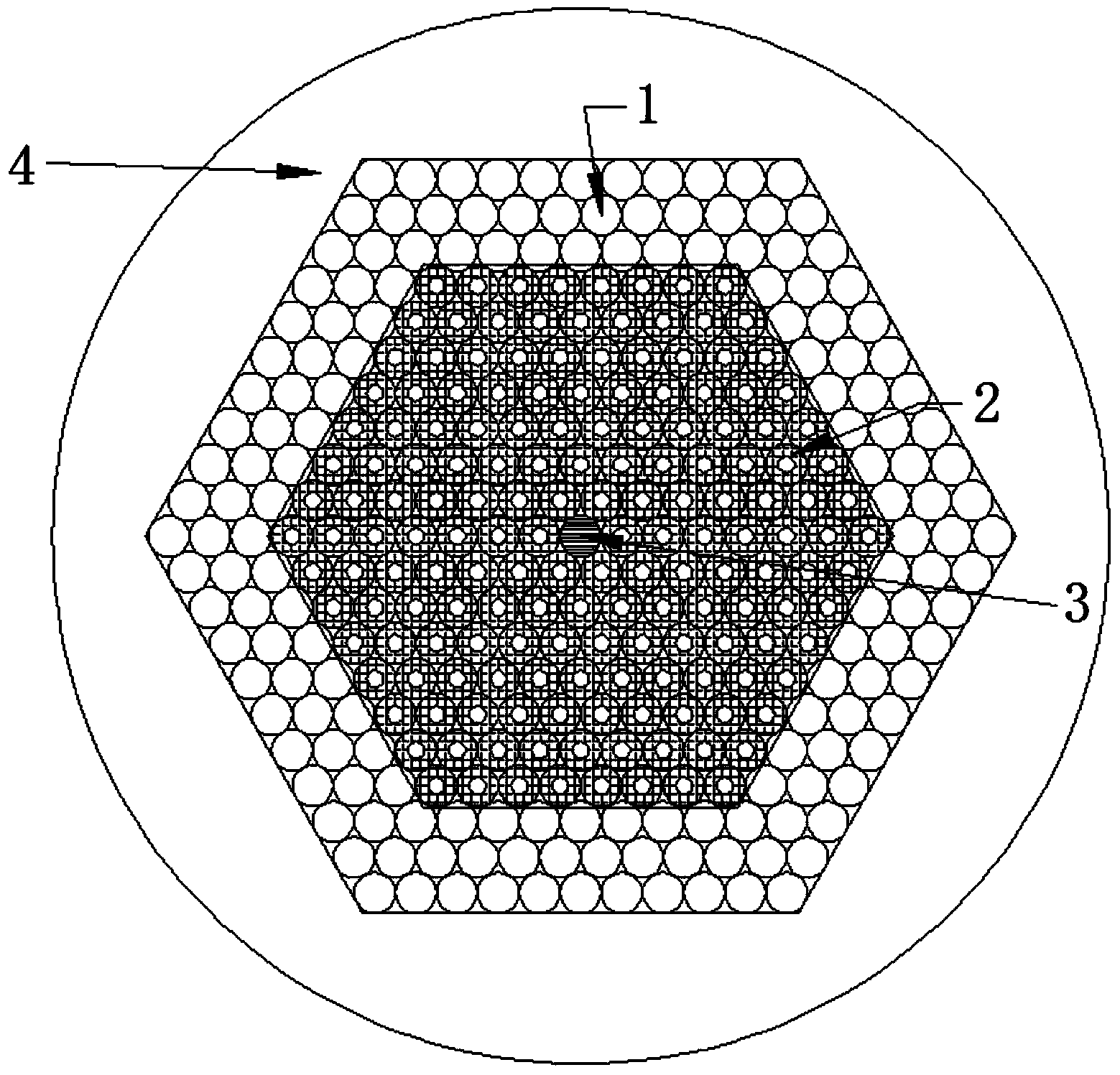

[0027] The first glass rod 1, the second glass rod 2 and the third glass rod 3 are made by using a drawing tower, the first glass rod 1 is a uniform thin rod of undoped glass, and the third glass rod 3 is a doped glass uniform thin rod, the second glass rod 2 is composed of core glass and cladding glass, the refractive index of the core glass is lower than that of the cladding glass, and the cladding glass finally becomes the optical fiber inner cladding layer, the refractive index of the first glass rod 1 is smaller than the refractive index of the cladding glass of the second glass rod 2, the refractive index of the third glass rod 3 is smaller than the refractive index of the cladding glass of the second glass rod 2, Then according to the require...

Embodiment 1

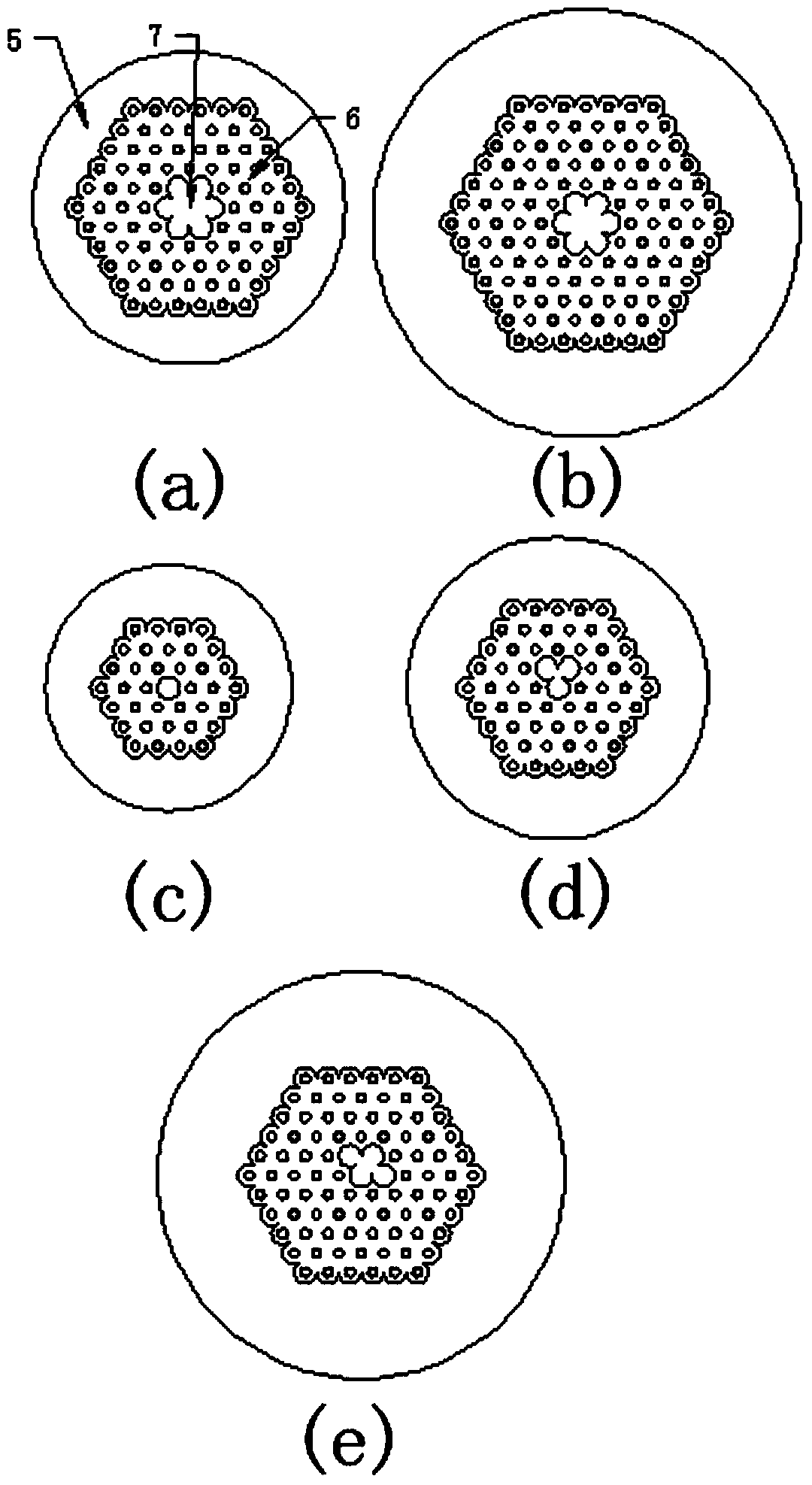

[0034] Using fluoride glass as the matrix material, the double-clad all-solid-state photonic crystal fiber is fabricated by stacking method (see figure 2 (a)). The first glass rod 1 and the second glass rod 2 are respectively undoped fluoride glass, and the third glass rod 3 is Tm-doped fluoride glass with a doping concentration of 3000ppm. The refractive indices of the first glass rod 1 and the third glass rod 3 are (at ~1500nm) 1.49 and 1.505 respectively, and the glass transition temperatures are 450°C and 470°C respectively, and the cladding glass and core glass of the second glass rod 2 have The refractive index (~1500nm) is 1.51 and 1.49 respectively, the glass transition temperature is 455°C and 450°C, the outer diameter of the three kinds of glass rods is 1mm (the error is less than 1%), and the length is 15cm. Close-packed glass rods in a metal sleeve, where the number of layers of preformed rods is m=7, the number of layers replaced by the outermost layer is n=2, a...

Embodiment 2

[0037] Quartz glass is used as the host material, and the stacking method is used to make double-clad all-solid-state photonic crystal fibers (see figure 2 (b)). The first glass rod 1 is fluorine-doped quartz glass with a refractive index (at 1 μm) of 1.447, the cladding glass of the second glass rod 2 is undoped quartz glass, and the core glass is fluorine-doped quartz glass with a refractive index of 1.447. (at 1μm) are 1.45, 1.445 respectively. The third glass rod 3 is Yb-doped quartz glass with a concentration of 3000ppm and a refractive index of 1.449. The outer diameter of the three kinds of glass is 0.8mm (the error is less than 2%), and the length is 15cm. Nine layers (m=9) of the first glass rods 1 are densely packed in the metal sleeve, the outermost 3 layers (n=3) of the first glass rods 1 are replaced by the second glass rods 2, and the center 7 is replaced by the third glass rod 3 A first glass rod 1 was sintered at 1800° C. for 15 minutes. Draw the filament ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com