Modified aluminum pigment and preparation method thereof

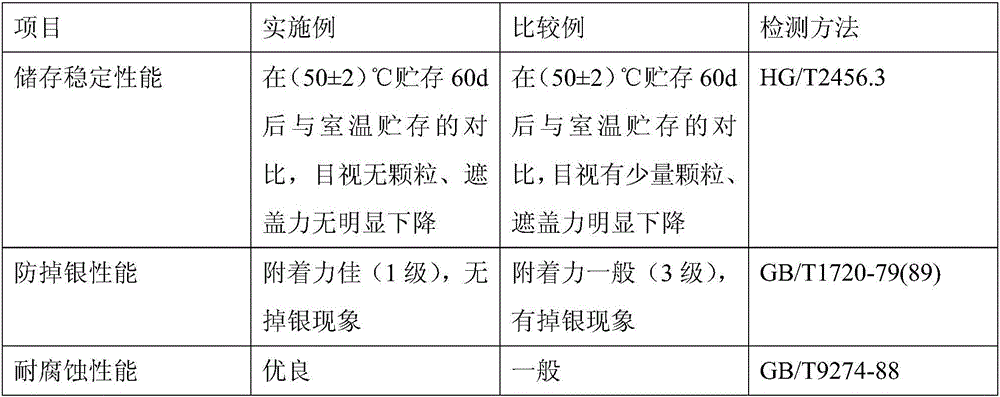

A technology of aluminum pigment modification, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., to achieve the effects of excellent storage stability, excellent anti-silver performance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the above-mentioned modified aluminum pigment, comprising the following steps,

[0030] Step A, preparation of the composition: graphene oxide and fatty acid were stirred and reacted at 80-90° C. for more than 5 hours to obtain the composition; at this temperature, graphene oxide (such as the oxygen-containing functional group therein) and fatty acid produced A chemical reaction produces the composition.

[0031] Step B, ball milling spherical aluminum powder into flake aluminum powder: adding organic solvent, micron-sized spherical aluminum powder and the composition prepared in step A into a ball mill for ball milling, ball milling spherical aluminum powder into flake aluminum powder, and filtering Obtain the filter cake containing flaky aluminum powder afterward;

[0032] Step C, sieving and classifying: sieving the flake aluminum powder in the filter cake obtained in step B into more than two grades of flak...

Embodiment

[0044] exist In the horizontal ball mill, load 2000kg of 1.0mm steel balls, add 300kg of organic solvent (200# solvent oil), D 50 80kg of 8.8μm nitrogen atomized fine spherical aluminum powder, 4kg of graphene oxide oleic acid composition, ball milled for 24 hours, discharged, sieved, filtered through 500 mesh material, and the filtrate was returned to the ball milling process. The filter cake was surface treated by kneading (replenishment of graphene oxide oleic acid composition during kneading). The packaging is an aluminum silver paste product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com