Preparation method for novel energy-saving anode steel claw

An anode steel claw, a new technology, applied in the field of anode steel claws with a new structure, can solve the problems that it is difficult to achieve the resistivity of electrolytic aluminum anode steel claws, poor controllability of burning elements, and unguaranteed purity. Achieve the effects of superior electrical conductivity, flexible types, and short welding operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

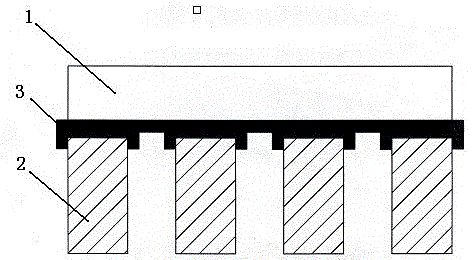

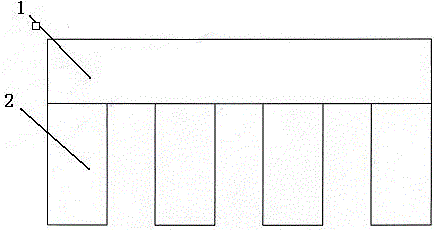

[0020] A new type of energy-saving anode steel claw, including a cross arm 1 and a claw head 2, which is characterized in that the cross arm 1 and the claw head 2 are fixed together by electroslag welding 3;

[0021] The preparation method of the above-mentioned novel energy-saving anode steel claw is as follows:

[0022] (1) Prepare the cuboid claw head and the cylindrical metal cross arm parent blanks in advance, the blank material is Q235, and place these two metal parent materials in the water-cooled mold cavity corresponding to the anode steel claw structure, and assemble and connect;

[0023] (2) Pour the melted flux into the water-cooled mold cavity, turn on the power supply, and the welding flux is made of CeO 2 , CaF 2 , CaCO 3 , AL 2 O 3 , Composition, of which the content of each component by mass percentage is: CeO 2 5-18%, CaF 2 43-58%, CaCO 3 5-15%, AL 2 O 3 18-25%;

[0024] (3) The co-solvent is matched with the secondary low voltage and current output from the transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com