Method for eliminating oil stains of dyed cotton fabric

A technology for pure cotton fabrics and oil stains, applied in the direction of dyeing methods, chemical instruments and methods, detergent compositions, etc., can solve problems such as inability to eliminate oil stains on pure cotton fabrics, oil stains on pure cotton fabrics, and difficult cleaning of dyeing liquor pipelines, and achieve Improve product qualification rate and production efficiency, control production costs, reduce loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

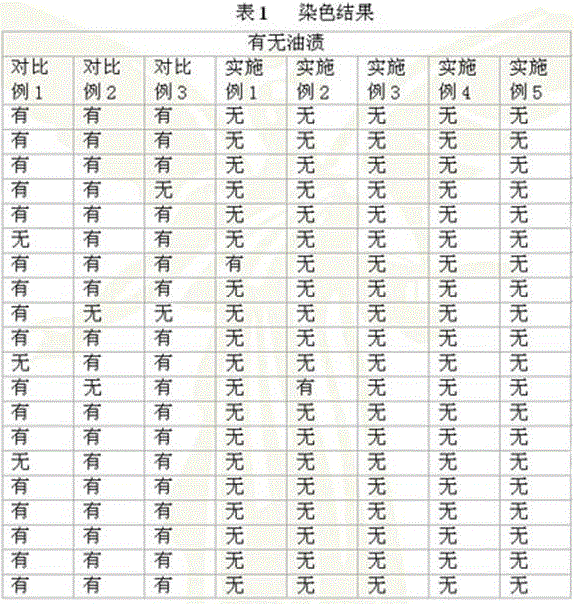

Examples

Embodiment 1

[0026] A method for eliminating oily stains on dyed pure cotton fabrics, comprising the steps of:

[0027] 1) Before dyeing, clean the dyeing device system including the emulsification tank, the dyeing batching tank and the dyeing tank with multiple dyeing liquid pipes leading into the dyeing liquid; the cleaning agent is the complex of caustic soda and hydrogen peroxide, the amount of caustic soda and hydrogen peroxide The ratio is 4:1.

[0028] 2) When dyeing, add the defoaming agent into the emulsification tank with other dyeing auxiliaries, do not stir the emulsification tank immediately, continue to stir for 2-5 minutes after 3 minutes, and then send the stirred dyeing auxiliaries into the dyeing process .

Embodiment 2

[0030] A method for eliminating oily stains on dyed pure cotton fabrics, comprising the steps of:

[0031] 1) Before dyeing, clean the dyeing device system including the emulsification tank, the dyeing batching tank and the dyeing tank with multiple dyeing liquid pipes leading into the dyeing liquid; the cleaning agent is the complex of caustic soda and hydrogen peroxide, and the The dosage ratio is 5:1.

[0032] 2) When dyeing, add the defoaming agent into the emulsification tank with other dyeing auxiliaries, do not stir the emulsification tank immediately, continue to stir for 2-5 minutes after 5 minutes, and then send the stirred dyeing auxiliaries into the dyeing process .

Embodiment 3

[0034] A method for eliminating oily stains on dyed pure cotton fabrics, comprising the steps of:

[0035] 1) Before dyeing, clean the dyeing device system including the emulsification tank, the dyeing batching tank and the dyeing tank with multiple dyeing liquid pipes leading into the dyeing liquid; the cleaning agent is caustic soda, hydrogen peroxide and oil emulsifier, caustic soda and hydrogen peroxide The dosage ratio is 6:1, the densities of caustic soda and hydrogen peroxide are both 35g / L, and the oil emulsifier is 8% of that of caustic soda and hydrogen peroxide.

[0036] 2) When dyeing, add the defoaming agent into the emulsification tank with other dyeing auxiliaries, do not stir the emulsification tank immediately, continue to stir for 2-5 minutes after 5 minutes, and then send the stirred dyeing auxiliaries into the dyeing process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com