Treatment methods of paint wastewater and coated broken paper

A paint wastewater and coating technology, applied in the field of papermaking, can solve the problems of low recycling rate, achieve the effect of improving filler retention and ash retention rate, reducing anion garbage content, and increasing the ash content of base paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

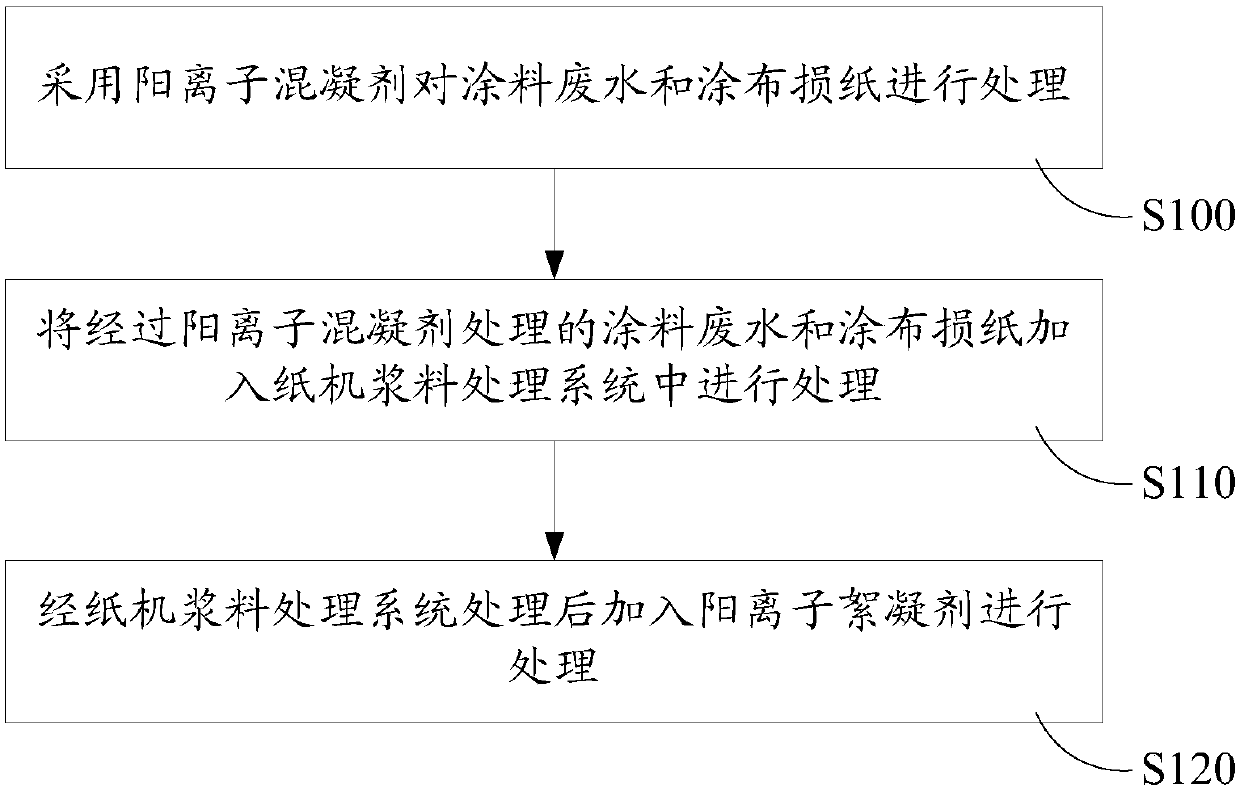

Method used

Image

Examples

Embodiment 1

[0044] Take OMC broken paper, paint wastewater, PA modified PAC to treat paint wastewater, paint wastewater concentration 4%, PA modified PAC addition is 5kg; use 0.5kg cationic polyacrylamide (C-PAM) modified PAC to treat OMC Wastewater, C-PAM molecular weight 1000k Da, charge density 5meq / g. Control the ratio of OMC broken paper and paint wastewater to 1:0.1. After mixing, the mixture was refined with a Wally refiner, and the difference in freeness before and after refining was controlled to be 50 mL. Finally, 3 kg of ultra-high molecular weight polyacrylamide was added, with a molecular weight of 20,000 kDa and a charge density of 10 meq / g. After mixing evenly, make slurry with fresh slurry according to the ratio of 20 / 80. Among them, fresh pulp accounts for 80%, and the ratio of fresh pulp is 20 / 70 / 10 to prepare NBKP, LBKP, BC or APMP. Finally, fillers, starch, cationic polyacrylamide, and anionic filter aid are added to prepare a thin slurry, and a small-scale sheet-mak...

Embodiment 2

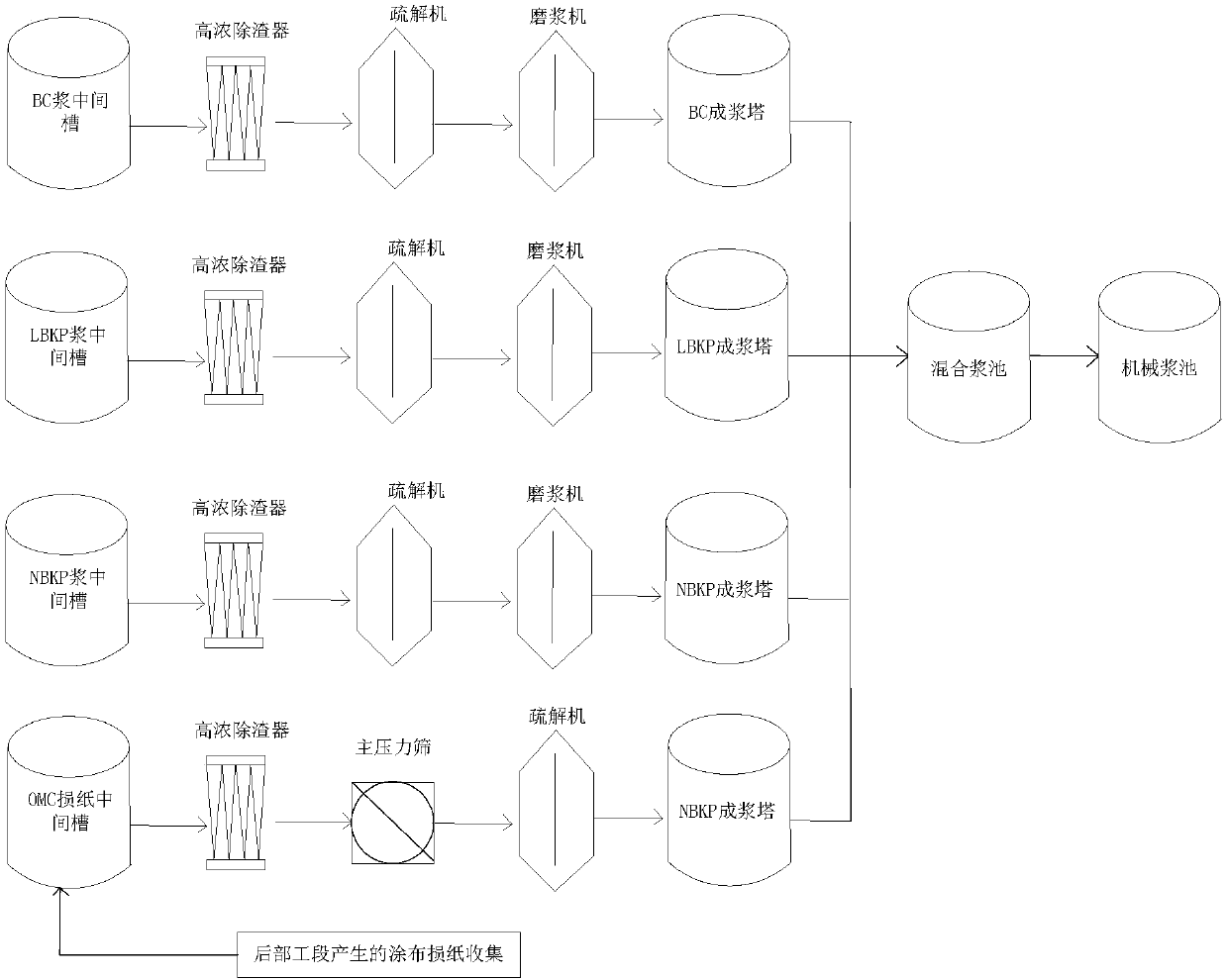

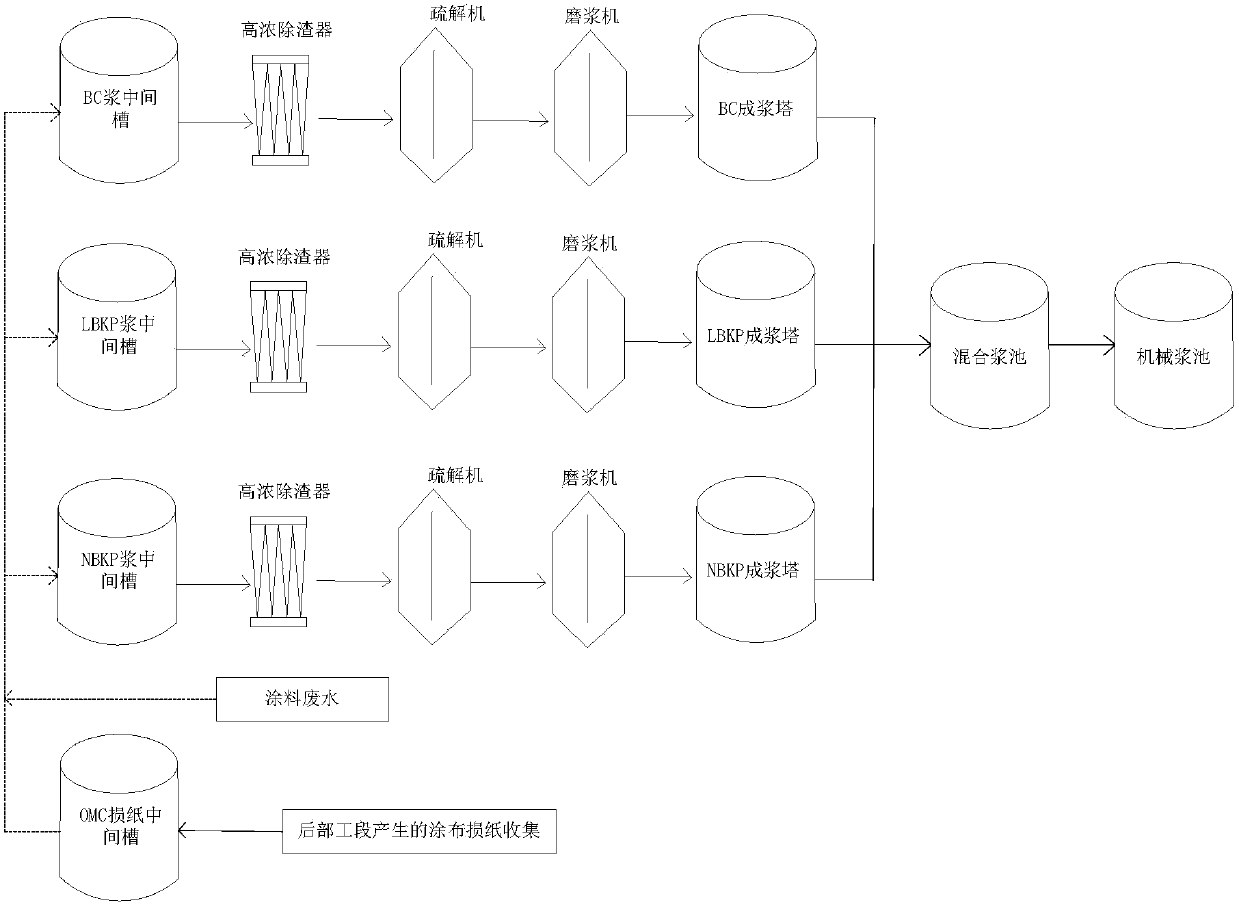

[0048] Pump the slurry and paint waste water in the OMC broken paper barrel tank to the NBKP refining intermediate tank of the stock stock preparation section, and refine the OMC broken paper and paint mixture through one of the 2 NBKP refining lines, and then and NBKP enter the NBKP pulping tower according to a certain ratio, and finally through the direct pulping process, the OMC broken paper and coating wastewater are mixed and refined, and the mixed pulp enters the paper machine papermaking process according to a certain ratio. Among them, the concentration of paint wastewater is controlled at 18%, and 4kg PAC is added for treatment, and the addition point is the paint wastewater tank; the concentration of OMC broken paper is controlled at 5.5%, and PEI modified PAC is added to treat OMC broke paper. The molecular weight of PEI is 200k Da, and the charge The density is 8meq / g, the addition amount is 2k g, and the addition point is from the OMC barrel tank to the pump suctio...

Embodiment 3

[0051]Pump the slurry and paint waste water in the OMC broken paper barrel tank to the NBKP refining intermediate tank of the stock stock preparation section, use one of the 2 LBKP refining lines to refine the OMC broken paper and paint mixture, Then it enters the LBKP pulping tower with LBKP according to a certain ratio, and finally through the direct pulping process, the OMC broken paper and coating wastewater are mixed and refined, and the mixed pulp enters the paper machine papermaking process according to a certain ratio. Among them, the concentration of paint wastewater is controlled at 70%, and 0.5kg PAC is added for treatment. The adding point is the paint wastewater tank; the concentration of OMC broken paper is controlled at 4.5%, and PAE modified PAC is added to treat OMC broke paper. The molecular weight of PAE is 1200k Da, and the charge The density is 0.5meq / g, the addition amount is 5k g, and the addition point is from the OMC barrel tank to the pump suction inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com