Working device lifting and swinging connecting frame device used on roadside stone cleaning machine

A working device and swing connection technology, applied in road cleaning, cleaning methods, construction, etc., can solve problems such as abnormal work, high labor intensity, and potential safety hazards, and achieve the effects of simple structure, convenient maintenance, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

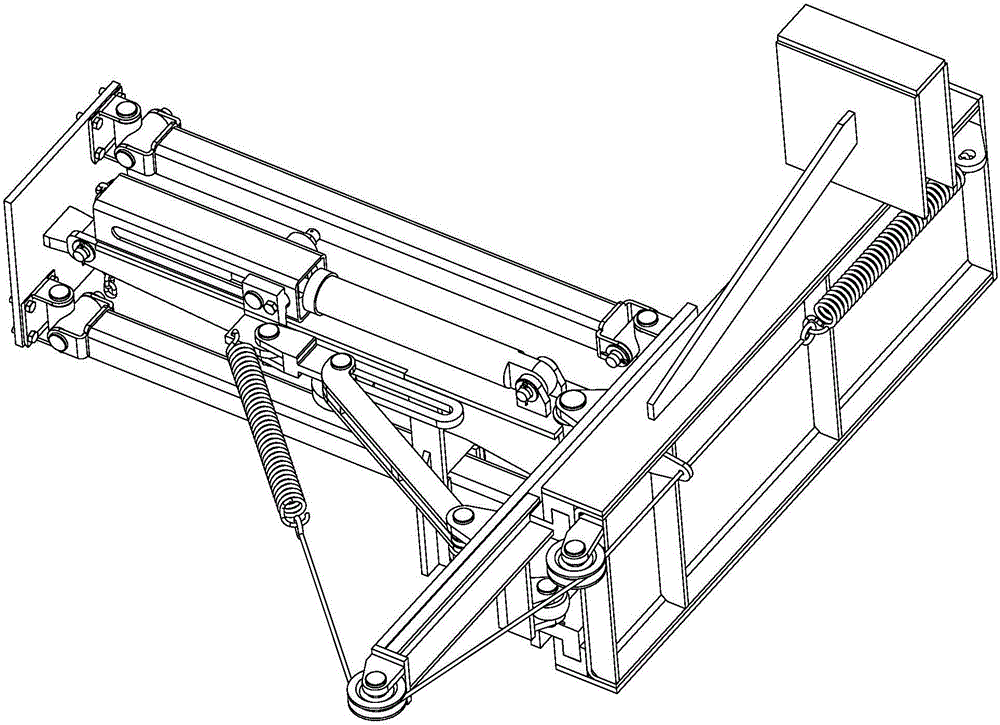

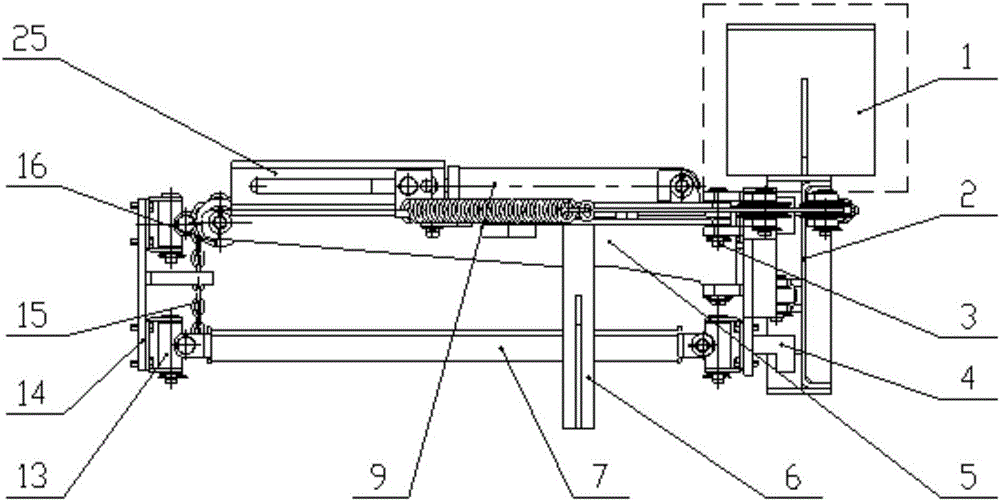

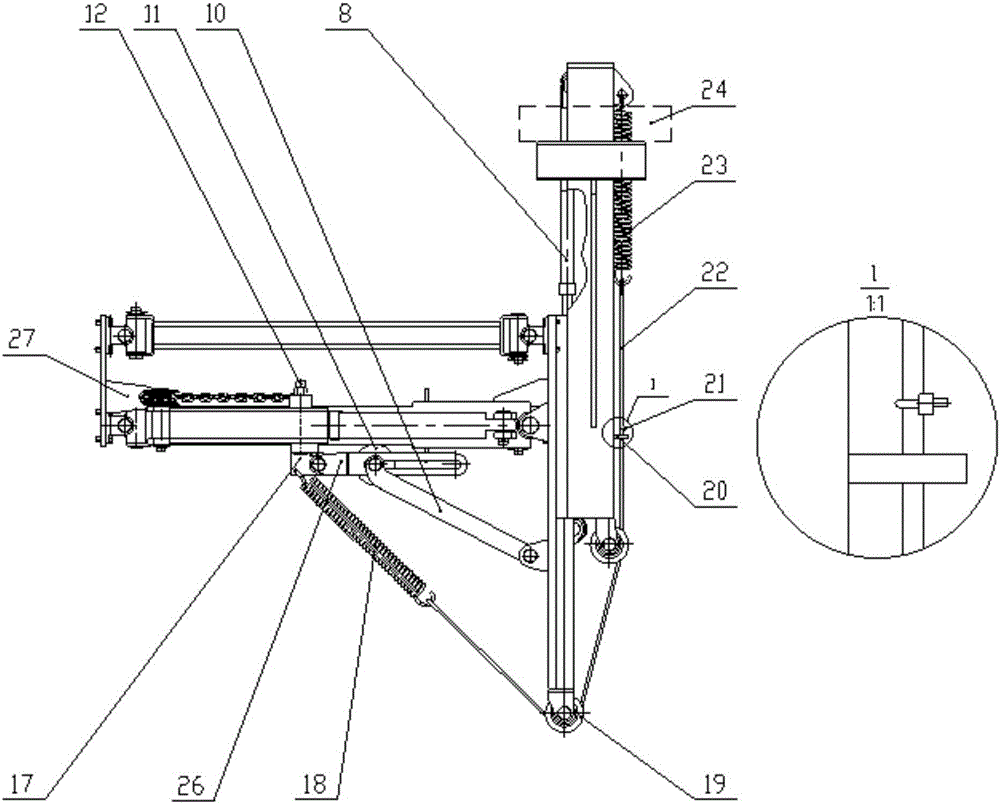

[0023] The following is attached figure 1 The given embodiment further describes in detail the lifting and swinging connecting frame device of the working device used on the curb cleaning machine of the present invention.

[0024] refer to Figure 1 to Figure 5 , a lifting and swinging connecting frame device for a working device on a curb cleaning machine, including a main connecting plate 1, a side vertical plate assembly 2, a main sliding vertical plate assembly 4, a horizontal swing arm assembly 5, and left and right limiters Plate 6, lifting swing connecting rod 7, side telescopic oil cylinder 8, lifting swing oil cylinder 9, auxiliary pull rod 10, connecting plate 14 of cleaning working device, chain 15, guide wheel 16, connecting slider 17, auxiliary tension spring 18, fixed pulley 19 , limit plate 20, limit fixed block 21, steel wire rope 22, preload spring 23, limit square tube 25, limit groove plate 26, chain limit plate 27.

[0025] The main connecting plate 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com