Ratchet mechanism

A ratchet mechanism and ratchet technology, which is applied to mechanical equipment, belts/chains/gears, transmission devices, etc., can solve the problems of small ratchet mechanism precision, difficult spring manufacturing, and difficult realization, so as to ensure high precision and simple processing technology , good practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

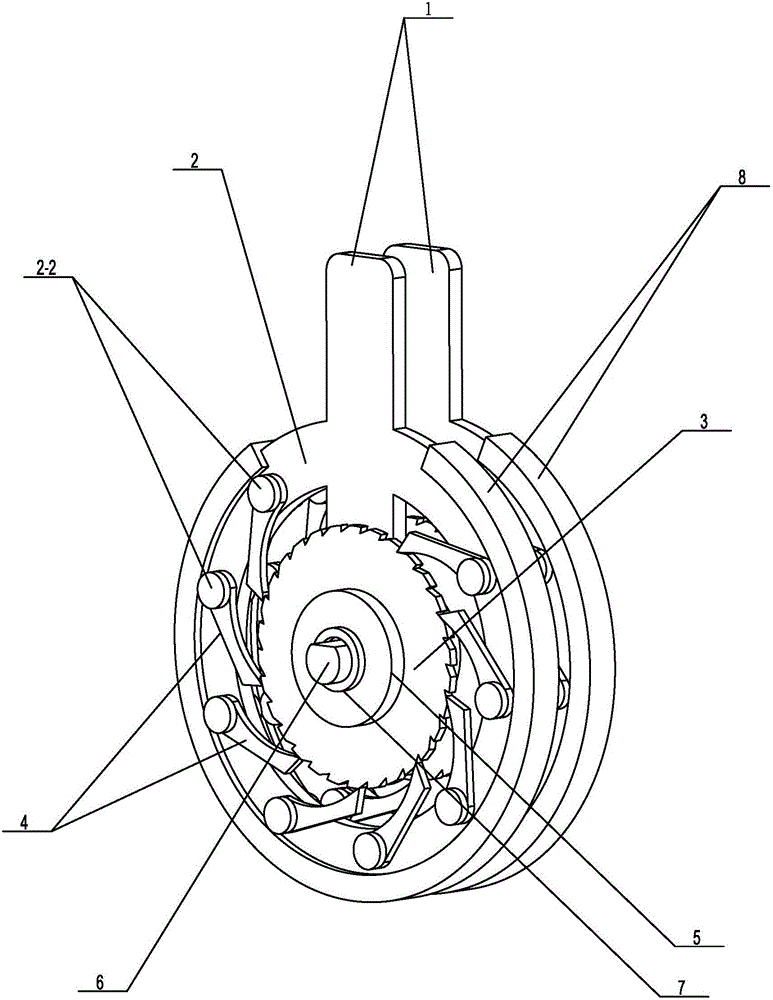

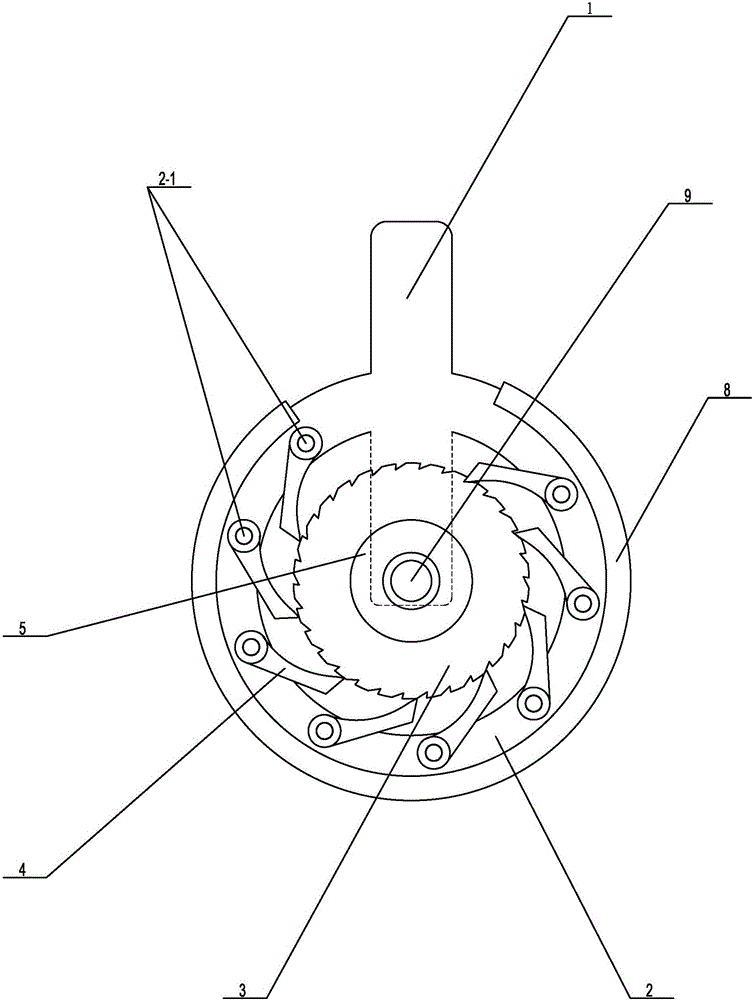

[0019] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention is proposed, a multi-claw ratchet mechanism, including a rocker 1, and a hollow support ring 2 is provided on the rocker 1. In this embodiment, the rocker 1 has an end rod for supporting The support ring 2 is provided with several circular holes 2-1. In this embodiment, 8 circular holes 2-1 are preferably arranged, and the 8 circular holes 2-1 are hinged with magnetic material. The other ends of the ratchets 4 and 8 are all attached to the ratchet 3 located in the round hole of the support ring 2, and one side of the ratchet 3 is provided with ring magnets 5 and 8 that can make the ratchet 4 generate magnetic force A magnetic force is formed between the ratchet 4 and the ring magnet to attach to the teeth of the ratchet 3. In this embodiment, adjacent ratchets 4 are evenly spaced by 25 / 8 teeth, and the rocker 1 swings 8 times, and the ratchet 3 After turning a tooth pitch angle, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com