Probe of eddy current sensor and eddy current sensor

An eddy current sensor and cable technology, which is applied in the direction of instruments, electric devices, and electromagnetic means, etc., can solve the problem that the sensor cannot accurately reflect the measured displacement, the sensor probe cannot withstand high temperature, unfavorable installation and displacement Detection and other problems, to achieve the effect of eliminating the influence of eddy current field, wide temperature compensation range, and reducing the size of the probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

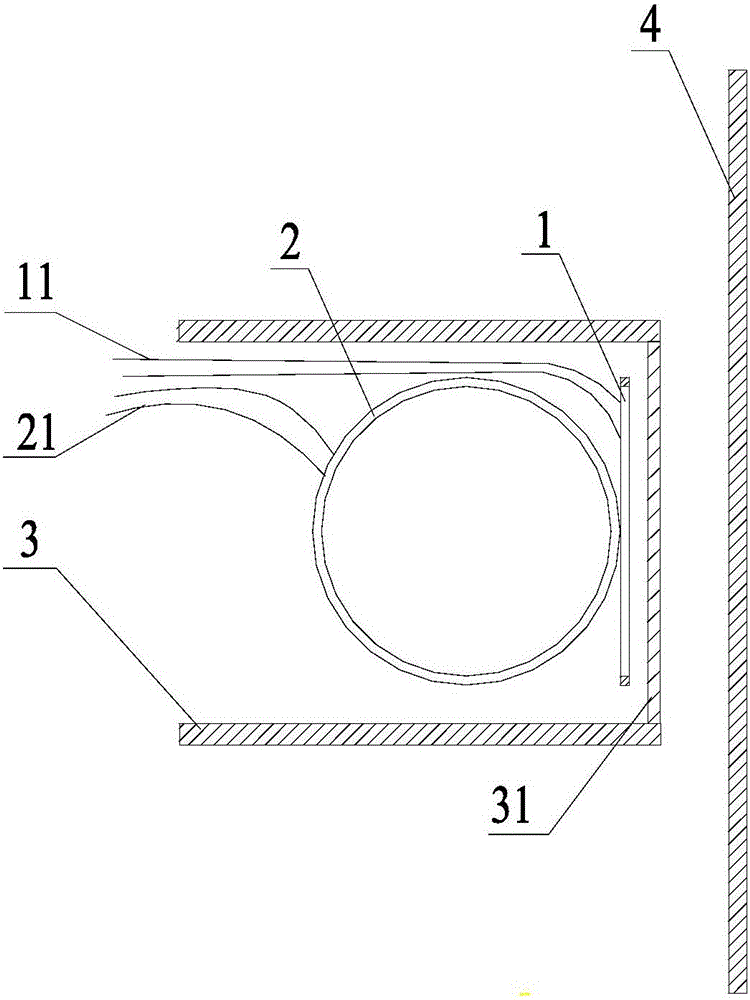

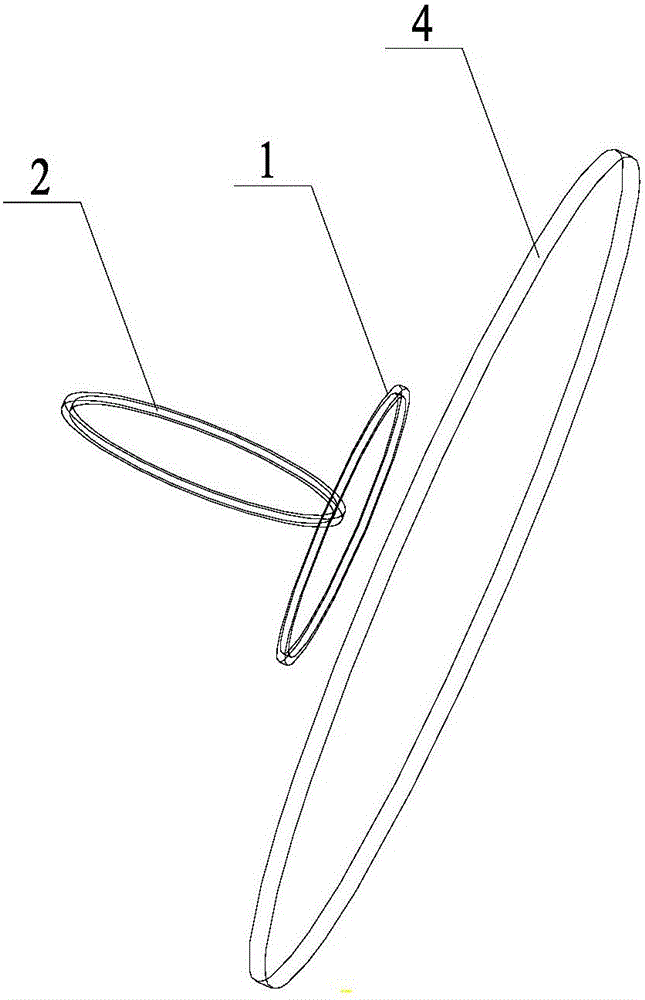

[0022] figure 1 This is a schematic plan view of a probe of an eddy current sensor provided in the first embodiment of the present invention. This embodiment may be suitable for reducing the size of the probe on the basis of ensuring the detection accuracy, and specifically includes: a detection coil 1 and a temperature compensation coil 2. The detection coil 1 is parallel to the detection surface 31 of the probe 3, and the temperature compensation coil 2 is perpendicular to the detection coil 1 and does not exceed the plane of the inner coil of the detection coil 1, wherein the inner side of the detection coil 1 The coil is a one-turn detection coil with the shortest distance from the detection surface 31.

[0023] According to Faraday’s law of electromagnetic induction, when the detection coil 1 in the probe 3 passes through a sinusoidal alternating current i 1 When the space around the detection coil 1 inevitably produces a sinusoidal alternating magnetic field H 1 , It makes t...

Embodiment 2

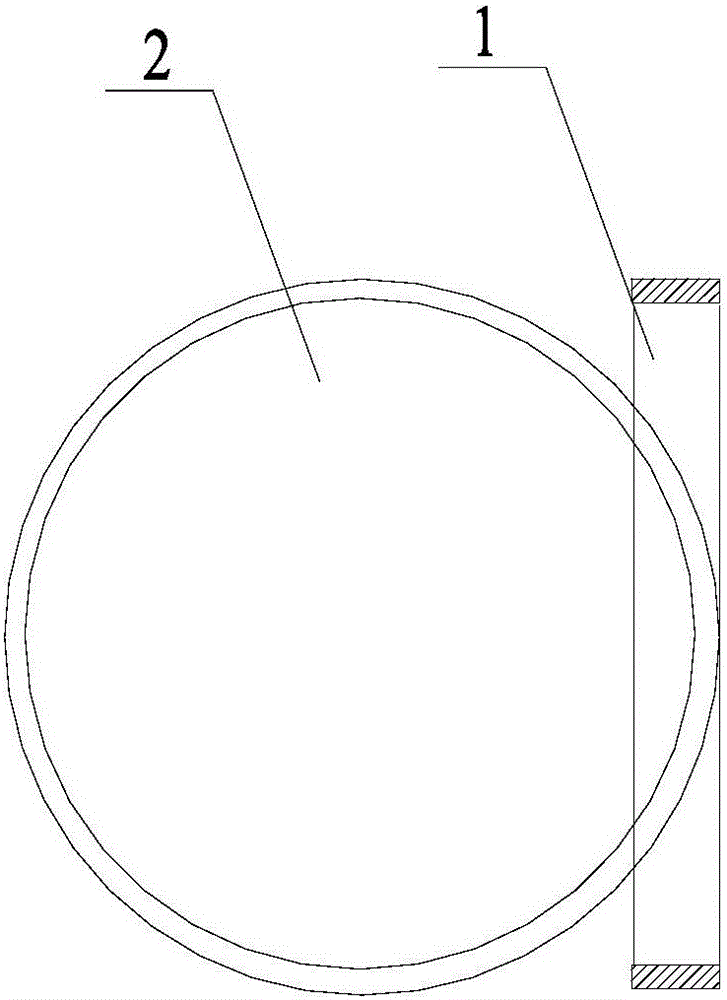

[0029] image 3 It is a schematic plan view of the probe of an eddy current sensor in the second embodiment of the present invention. The technical solution of this embodiment specifically limits the positions of the detection coil 1 and the temperature compensation coil 2 on the basis of the foregoing embodiment, specifically including: the outlines of the detection coil 1 and the temperature compensation coil 2 are both circular , The diameter of the inner coil of the detection coil 1 is tangent to the outer contour of the temperature compensation coil 2. The advantage of this design is to eliminate the influence of the temperature compensation coil 2 on the eddy current field of the detection coil 1 while reducing the size of the probe.

Embodiment 3

[0031] Figure 4 It is a schematic plan view of a probe of an eddy current sensor in the third embodiment of the present invention. The technical solution of this embodiment specifically limits the positions of the detection coil 1 and the temperature compensation coil 2 on the basis of the first embodiment, specifically including: the contours of the detection coil 1 and the temperature compensation coil 2 are both circular , The diameter of the inner coil of the detection coil 1 is separated from the outer contour of the temperature compensation coil 2, and the diameter of the outer coil of the detection coil 1 intersects the outer contour of the temperature compensation coil 2, wherein The outer coil of the detection coil 1 is the one-turn detection coil that is the farthest from the detection surface. The advantage of this design is to eliminate the influence of the temperature compensation coil 2 on the eddy current field of the detection coil 1 while reducing the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com