Turbine tester

A testing device and turbine technology, which is used in measurement devices, engine testing, and machine/structural component testing. The number of iterations, the accuracy of test data, and the effect of saving R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The turbine testing device provided by the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

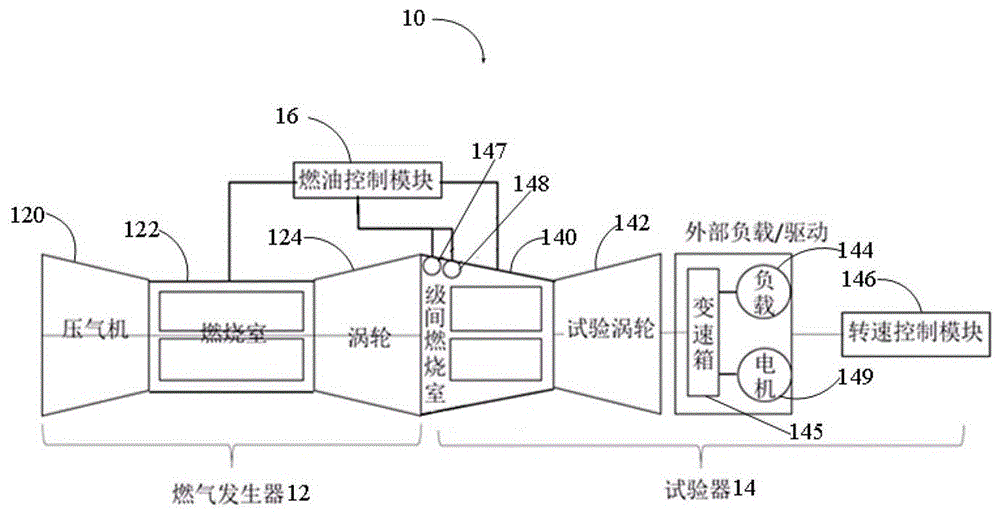

[0022] see figure 1 , The turbine testing device 10 provided by the embodiment of the present invention includes: a gas generator 12 , a tester 14 and a fuel control module 16 . The gas generator 12 includes: a compressor 120 , a combustion chamber 122 and a working turbine 124 . The tester 14 at least includes: an interstage combustion chamber 140 and a test turbine 142 . The interstage combustion chamber 140 is arranged behind the gas generator 12 , so that the high temperature and high pressure gas in the combustion chamber 122 can enter the interstage combustion chamber 140 after passing through the working turbine 124 . The test turbine 142 is arranged behind the interstage combustion chamber 140 , so that the high temperature and high pressure gas in the interstage combustion chamber 140 can flow thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com