Measurement Method of Harmonic Impedance of Traction Power Supply System

A traction power supply system, harmonic impedance technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems such as lightning arrester and other equipment burning, resonance overvoltage, explosion, etc., to reduce purchase and operation Cost reduction, reduced operating voltage, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

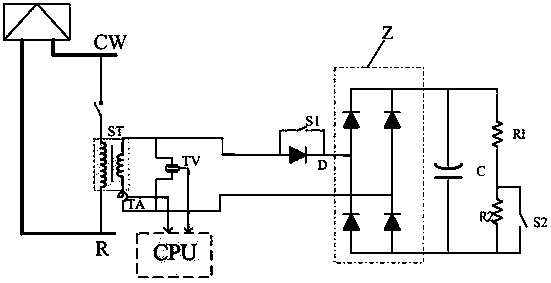

[0027] figure 1 It is shown that a specific embodiment of the present invention is a device for measuring harmonic impedance of a traction power supply system, which is composed of:

[0028] The two ends of the primary coil of the step-down transformer ST are respectively connected with the catenary CW and the rail R of the power supply section, and the current sensor TA is connected in series on the secondary coil, and the two ends of the secondary coil are connected in parallel with the voltage sensor TV; the current sensor TA The output ends of the voltage sensor and the TV are connected to the data processor CPU; the two ends of the secondary coil are also connected to the two output ends of the harmonic current source injection device; wherein, the specific composition of the harmonic current source injection device is:

[0029] One AC terminal of the bridge rectifier circuit Z is directly used as an output terminal of the harmonic current source injection device, the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com