Color-locking optical cable

An optical cable and color-locking technology, which is applied in the field of color-locked optical cables, can solve the problems of difficulty in the thickness of the marking strip of the sheath of the hanging wire, increase the weight and cost of the optical cable, and the unsatisfactory performance of the optical cable sheath, etc., to achieve convenient thickness control and fast production speed , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

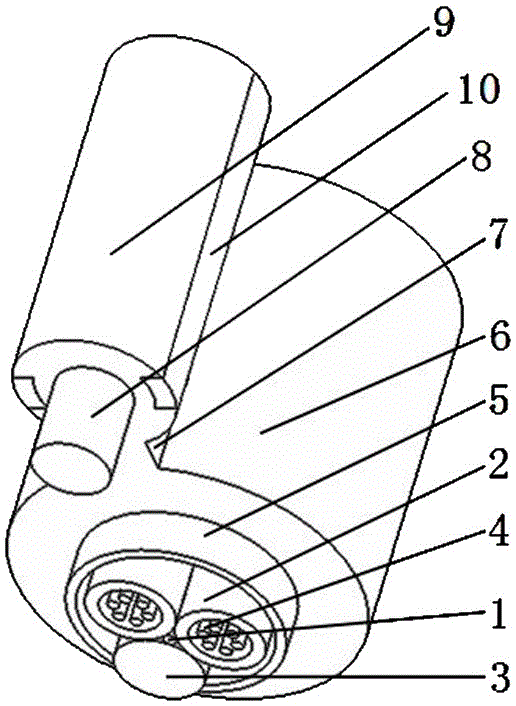

[0035] please seefigure 1 and figure 2 , a color-locking optical cable, which is composed of a cable core, an outer sheath 6 covering the cable core, a reinforcement element 8, a suspension wire sheath 9 covering the reinforcement element, and a rib 7 connecting the suspension wire sheath and the outer sheath The cable core is composed of a central central reinforcement 1, a filling rope 3 outside the central reinforcement, two loose tubes 2, and a protective layer 5 covering the filling rope and the loose tube; each There are six optical fibers 4 in the loose tube; it is characterized in that: the reinforcing element is a single phosphating steel wire, two marking strips 10 are symmetrically arranged on the suspension wire sheath, and the suspension wire sheath, outer sheath, and ribs are integrally formed The filling rope and multiple loose sleeves are twisted around the central reinforcement; the thickness of the marking strip is 0.5mm; the material of the outer sheath is ...

Embodiment 2

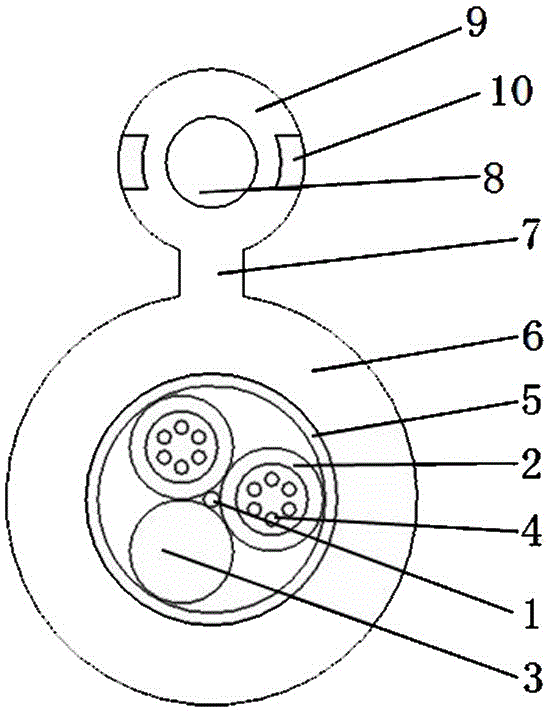

[0037] please see image 3 and Figure 4 , and refer to figure 1 and figure 2 , a color-locking optical cable, basically the same as the implementation example 1, the difference is that there are three filling ropes 3, and two loose tubes 2; the marking strip is made of the following raw materials by weight: the same as the outer sheath 95 parts of materials, 3 parts of commercially available polyethylene color masterbatch, 8 parts of titanium dioxide, 0.8 part of commercially available antioxidant 1010, and 3 parts of natural paraffin.

Embodiment 3

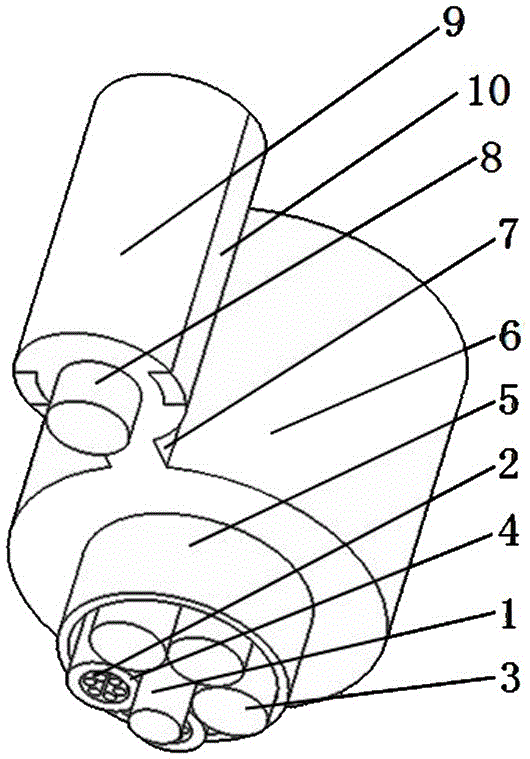

[0039] please see Figure 5 , and refer to image 3 and Figure 4 , a color-locking optical cable, basically the same as the implementation example 2, the difference is that there are two filling ropes 3, and three loose tubes 2; the marking strip is made of the following raw materials by weight: the same as the outer sheath 93 parts of materials, 1.5 parts of commercially available polyethylene color masterbatch, 7 parts of titanium dioxide, 0.6 parts of commercially available antioxidant 1010, and 2 parts of natural paraffin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com