Oxygen control device used for liquid lead or liquid lead-bismuth alloy loop system and method thereof

A liquid lead-bismuth alloy and loop system technology, which is applied in the direction of various fluid ratio control, etc., can solve problems such as constraints and structural steel corrosion, and achieve the effect of flexible operation scheme, easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

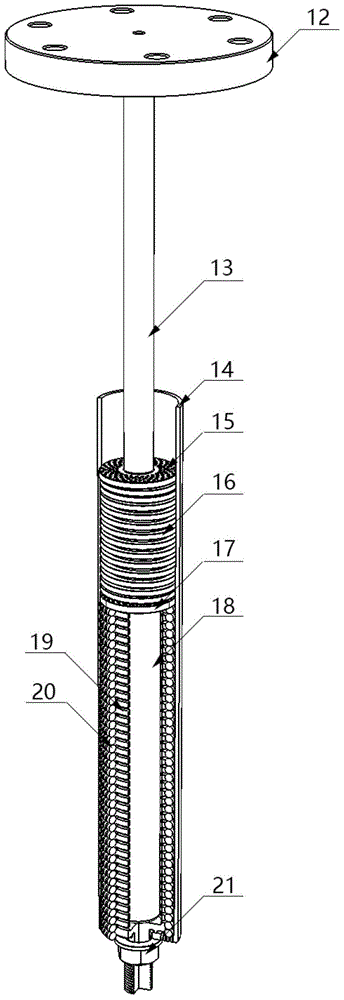

[0034] 1 Design of oxygen control device

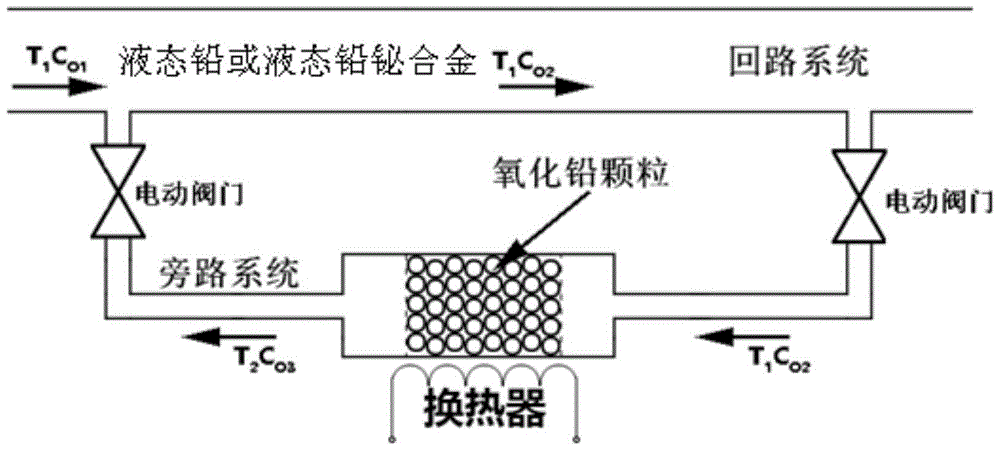

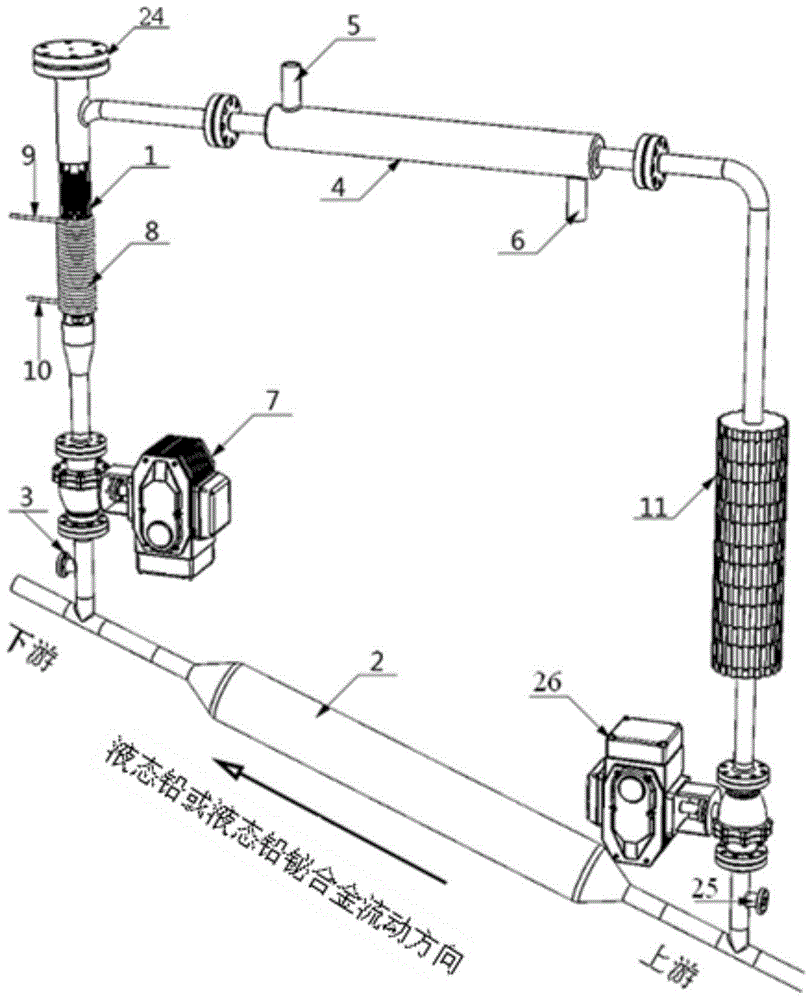

[0035] The oxygen control device is designed as a bypass system, so that when the liquid lead or liquid lead-bismuth alloy loop system is running, the mass exchanger 1 can be installed and removed without stopping the loop system; When liquid lead or liquid lead-bismuth alloy is used, the oxygen control device is enabled by opening the first electric valve 7 and the second electric valve 26; control device isolation.

[0036] The installation position of the bypass system is parallel to the driving pump 2, and the liquid lead or liquid lead-bismuth alloy enters the bypass system from the downstream of the driving pump 2, and returns to the loop system from the upstream of the driving pump 2.

[0037]The oxygen control device includes: a driving pump 2, two oxygen sensor interfaces, two electric valves, a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com