Non-contact transmission and positioning platform device and control method thereof

A positioning platform, non-contact technology, used in transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of lack of object pose detection and control functions, unfavorable for workpiece motion control, and small workpiece motion acceleration. Suppression of unstable vibration, excellent control performance, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

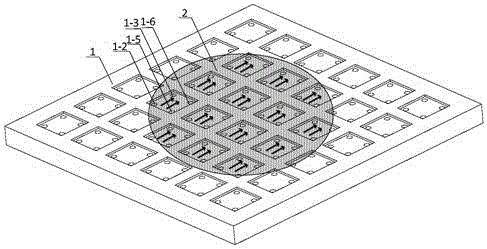

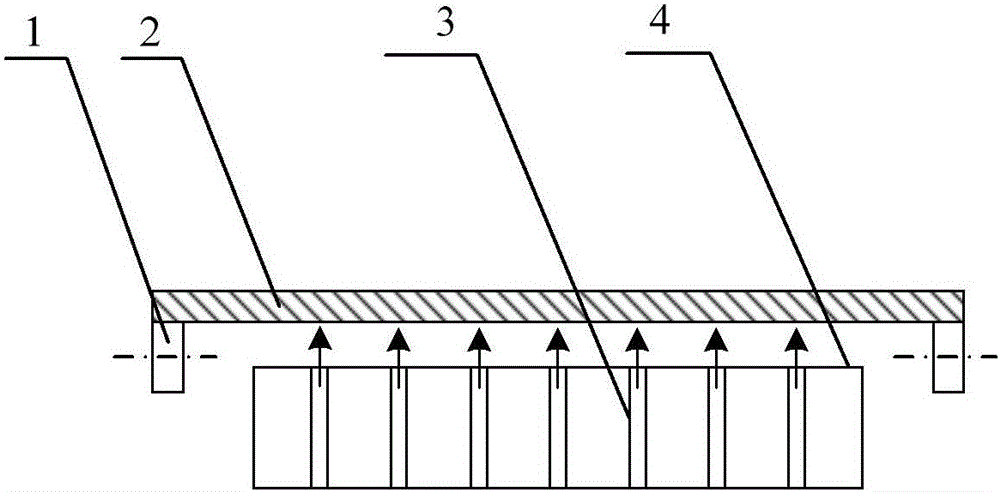

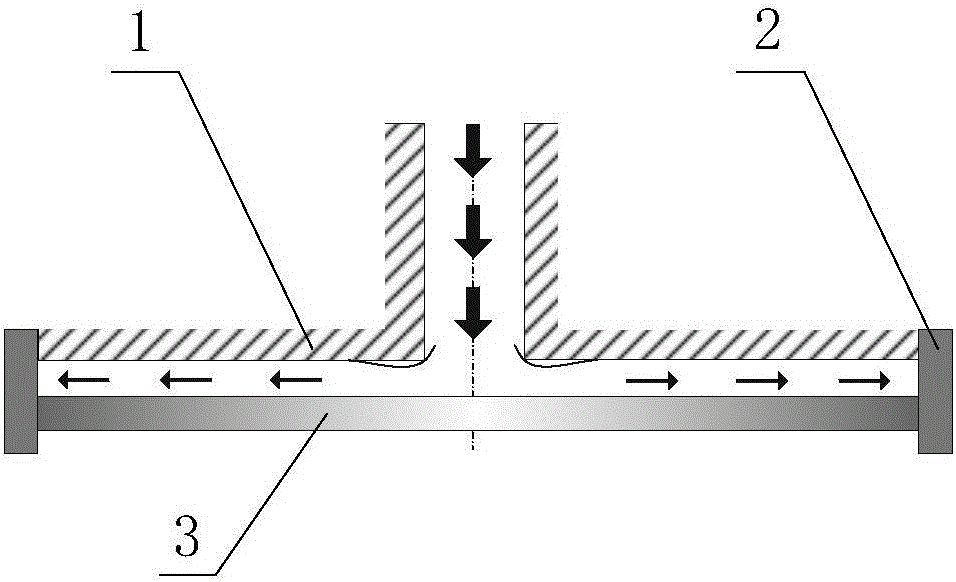

[0047] Such as Figure 4 to Figure 10 As shown, in the non-contact transportation and positioning platform device of the present invention, the transportation platform 2 is supported above the fixed platform 4 by the leveling nut 3, and the leveling nut 3 can adjust the levelness of the transportation platform 2; the fixed platform 4 and the base The seat 8 is rigidly connected by a threaded fixed platform support 15 to form a space for installing the pneumatic solenoid valve group 7 and pipelines, the pneumatic solenoid valve group 7, flow meters 6a, 6b, valve seat manifold 9, pressure reducing valve 5a, 5b is installed on the base 8 .

[0048] The positive pressure gas source is connected to the positive pressure reducing valve 5a through the connecting hose 15a, the output end of the positive pressure reducing valve 5a is connected through the intake hose 14a of the flowmeter, and the output end of the flowmeter 6a is converging through the valve seat The intake hose 13a o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com