An air flotation transport device

A technology of air flotation and air intake holes, which is applied in the direction of transportation and packaging, conveyors, non-mechanical conveyors, etc., can solve the problems of small driving capacity and workpiece disturbance, achieve easy layout, large motion acceleration, and reduce static electricity pollution And the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

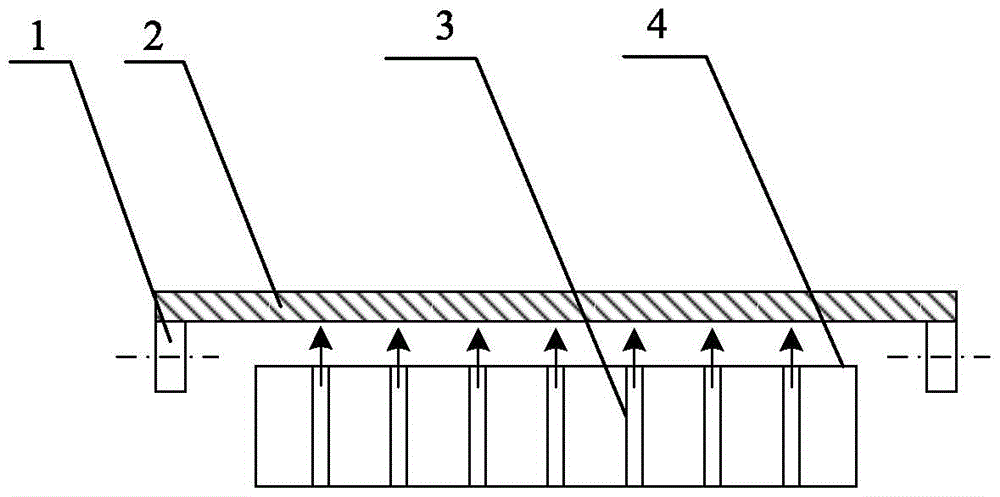

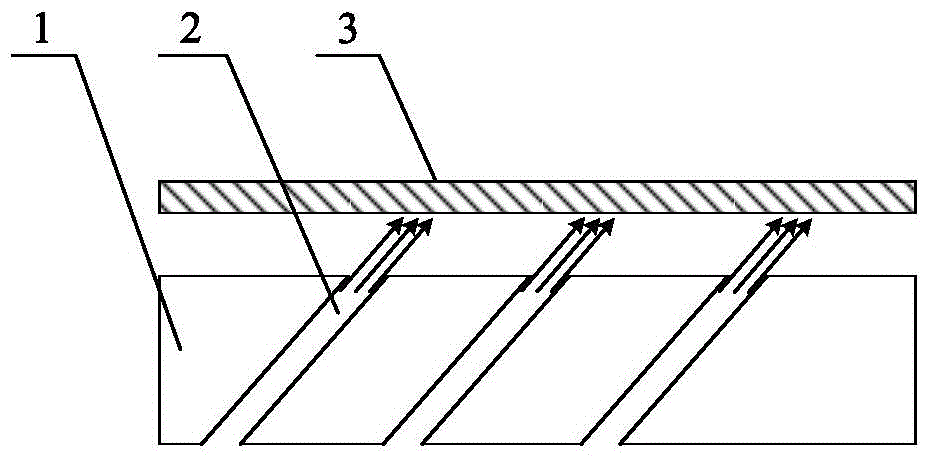

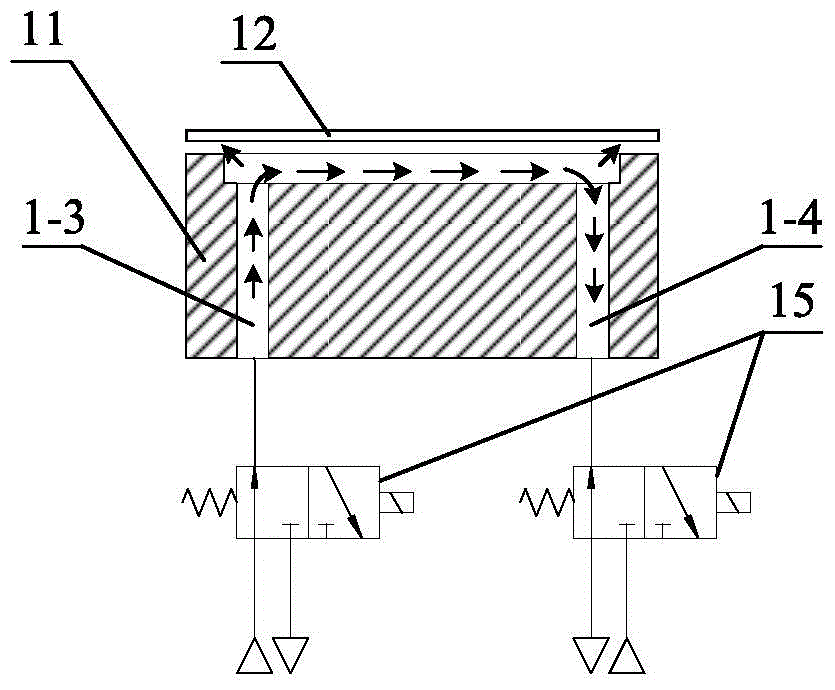

[0031] Such as Figure 3 to Figure 11 As shown, a kind of air flotation transportation device comprises a flat plate 11 with a smooth surface, the surface of the flat plate 11 is provided with a plurality of grooves 1-2 symmetrically distributed, and each groove 1-2 is separated from each other by the surface of the flat plate 11, And the number of grooves 1-2 is greater than 4. The grooves 1-2 on the surface of the plate 11 can be circular, square or cross-shaped, and the depth of the grooves 1-2 is greater than 200 microns and less than 500 microns. Air inlet 1-3 and air outlet 1-4 are provided in pairs in the groove 1-2, and screw thread is provided on the bottom surface of plate 11 where air inlet 1-3 and air outlet 1-4 are located, for connecting Gas connector for gas supply. Inlet holes 1-3 supply positive pressure, and air outlet holes 1-4 supply negative pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com