A continuous plate drawing system for a filter press

A filter press and filter plate technology, which is applied in the fields of papermaking, brewing, and sludge treatment industrial equipment manufacturing, can solve the problems of difficult maintenance, high energy consumption, and large space occupation, so as to achieve easy popularization and use, and solve the problem of filter plate sandwiching , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Figure 1-Figure 5 The traditional method of pulling the plate of the filter press uses a set of pulling plate mechanism. Driven by the motor, the plate is repeatedly taken and pulled to complete the work of removing the filter cake from the pulling plate of the entire filter press.

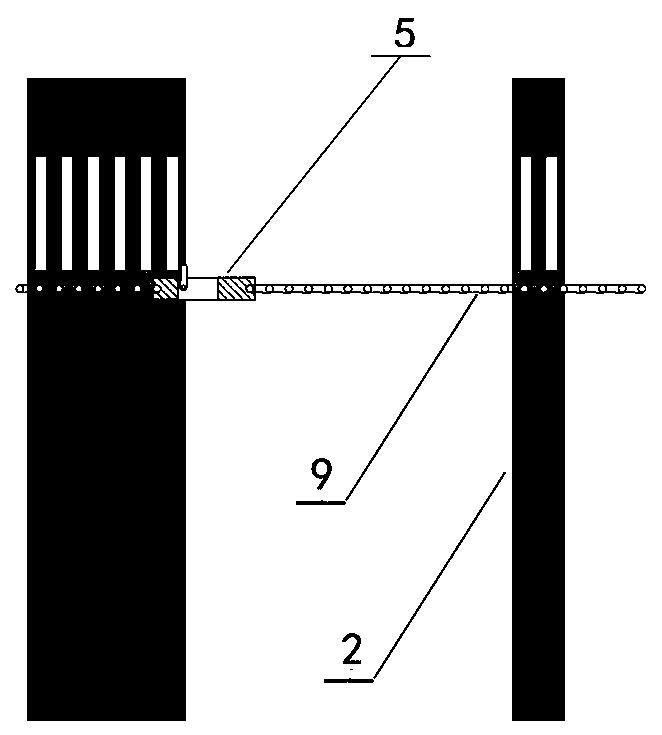

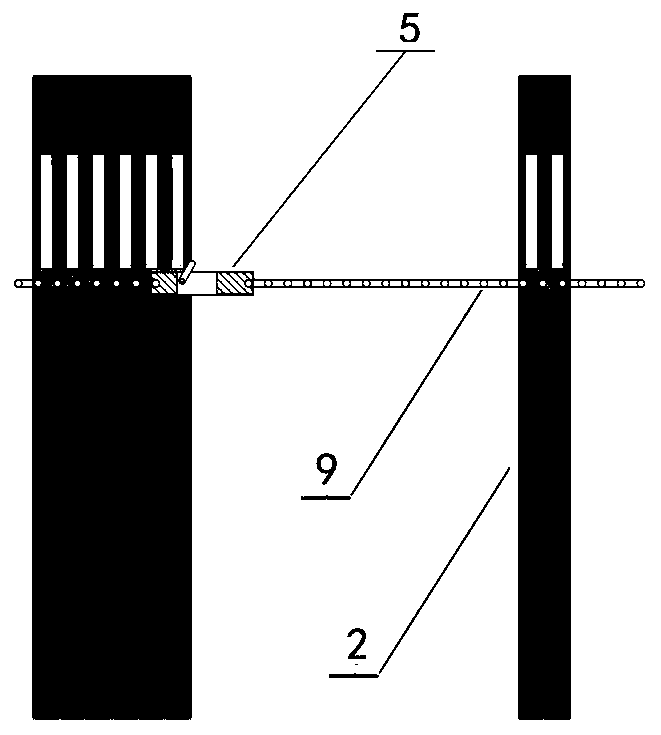

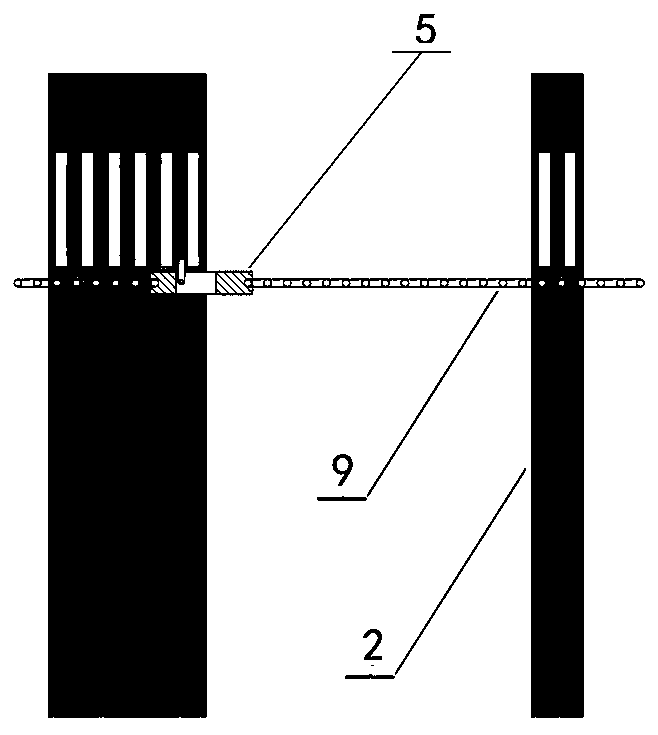

[0033] Figure 6-Figure 7 This is a schematic diagram of the three filter plates of the present invention as a group of drawing plates connected by connecting wires. The working process is that each time the drawing mechanism pulls the first filter plate of a group of filter plates, the first filter plate is Pull open each filter plate in this group in turn by pulling the string to make the filter cake in each filter plate of this group fall off. When the first filter plate of this group is close to the last filter plate of the previous group, push the previous group of filter plates to close, so that the previous group of filter plates are closed sequentially from the last one. When the previ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com