3D printer with power failure continuous printing function and printing method

A 3D printer, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of damage to the adhesive part, time-consuming and labor-intensive, etc., and achieve the effect of not increasing the cost of the circuit and not increasing the volume of the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

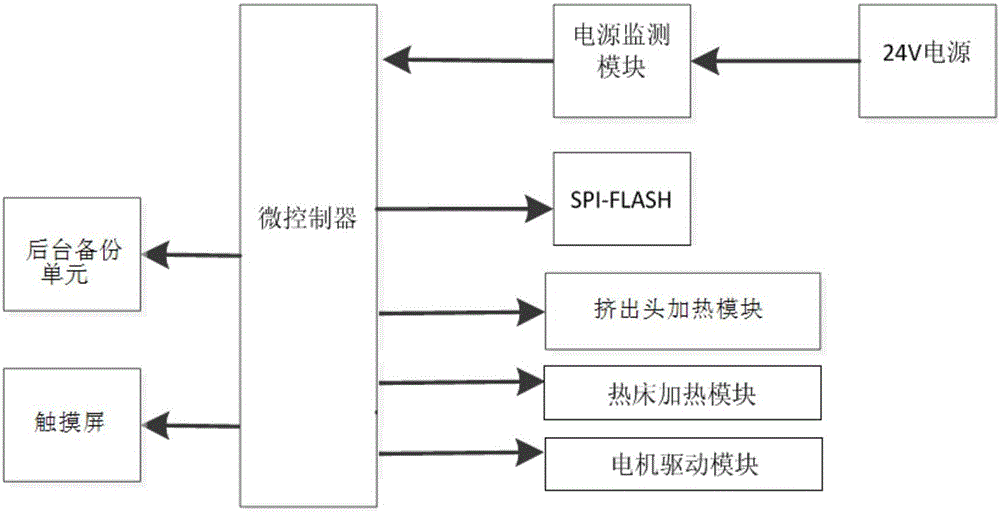

Method used

Image

Examples

example

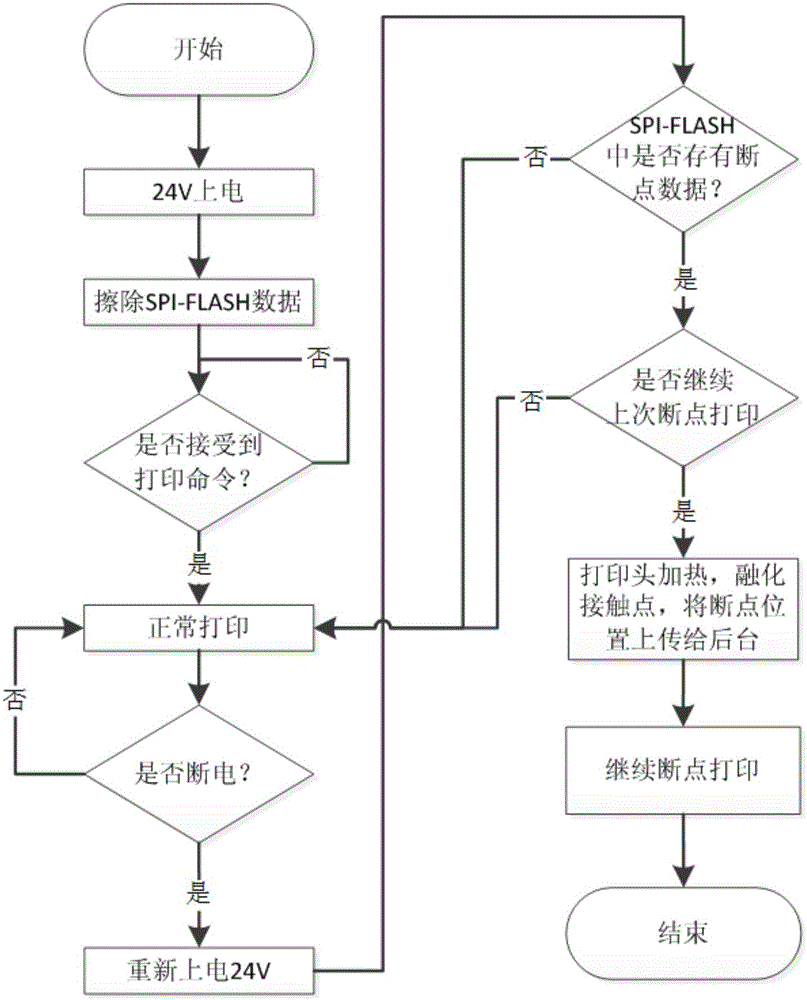

[0053] It takes 30 hours to print an avatar file. When the progress bar showed 90%, there was a sudden power failure, which caused the printing to be interrupted. This was discovered by the operator 4 hours later. At this time, the call has come, and the avatar is still a skull away, and the printer's UI will display whether to continue the previous printing.

[0054] The operator chooses to continue with the last print. At this time, the extrusion head starts to heat until it is heated enough that the extrusion head can be separated from the unfinished model, and the motor drive module drives the three-axis motor to move for mechanical reset. The extrusion head then continues to heat, and the thermal bed heating module of the printer also starts to heat, until both are heated to the specified temperature, and the microcontroller looks for the breakpoint of the last printing in SPI-FLAH. And map that breakpoint to the corresponding location in the gcode file. The printer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com