Drag reduction and efficiency enhancement ship

A ship and hull technology, applied in the direction of ship propulsion, hull, ship parts, etc., can solve the problems of not reaching the reverse rotation output power of the main engine propeller, affecting the reverse speed of the ship, affecting the power efficiency of the ship, etc., and achieving flexible and convenient steering , outstanding effect, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

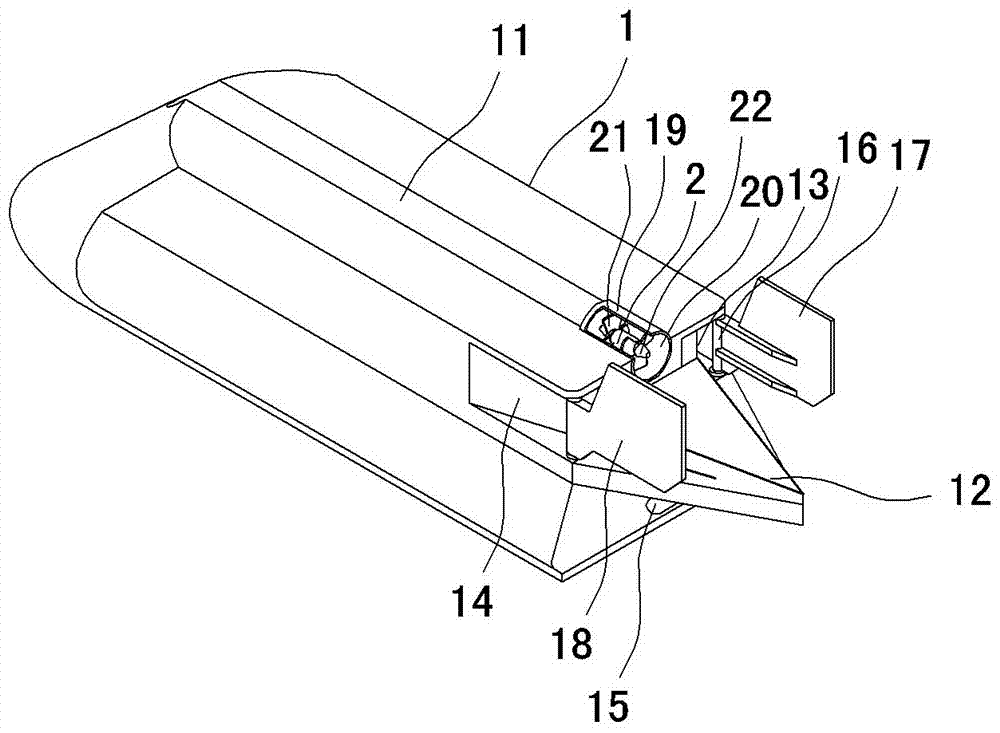

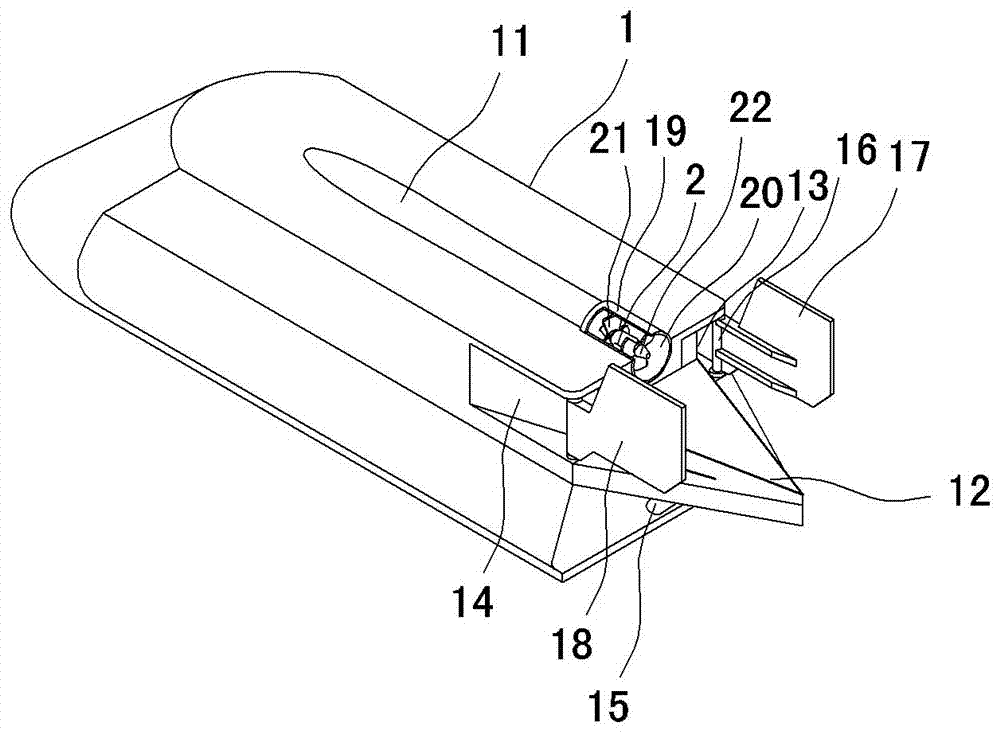

[0010] Embodiment one, such as figure 1 , figure 2 As shown, it includes a hull 1 and a propeller 2. The bottom of the hull 1 is forwardly provided with a diversion groove 11 recessed into the hull 1 and opening to the bottom and rear of the hull 1 from the rear of the hull 1. The rear portion stretches to the front of the hull 1 and opens to the front of the hull 1 or only stretches to a certain distance ahead of the rear of the hull 1. The propeller 2 is positioned in the diversion groove 11 and is installed on the hull 1. There is a vortex eliminator 12, the front side of the vortex eliminator 12 is connected to the upper and lower sides of the hull 1, and the lower side is located above the bottom of the diversion groove 11 and submerged below the water level line. The depth gradually deepens towards the left oblique water tank 13 that opens to the left and rear sides of the hull 1, and the stern of the hull 1 is located on the underwater right side wall. Right obliquel...

Embodiment 2

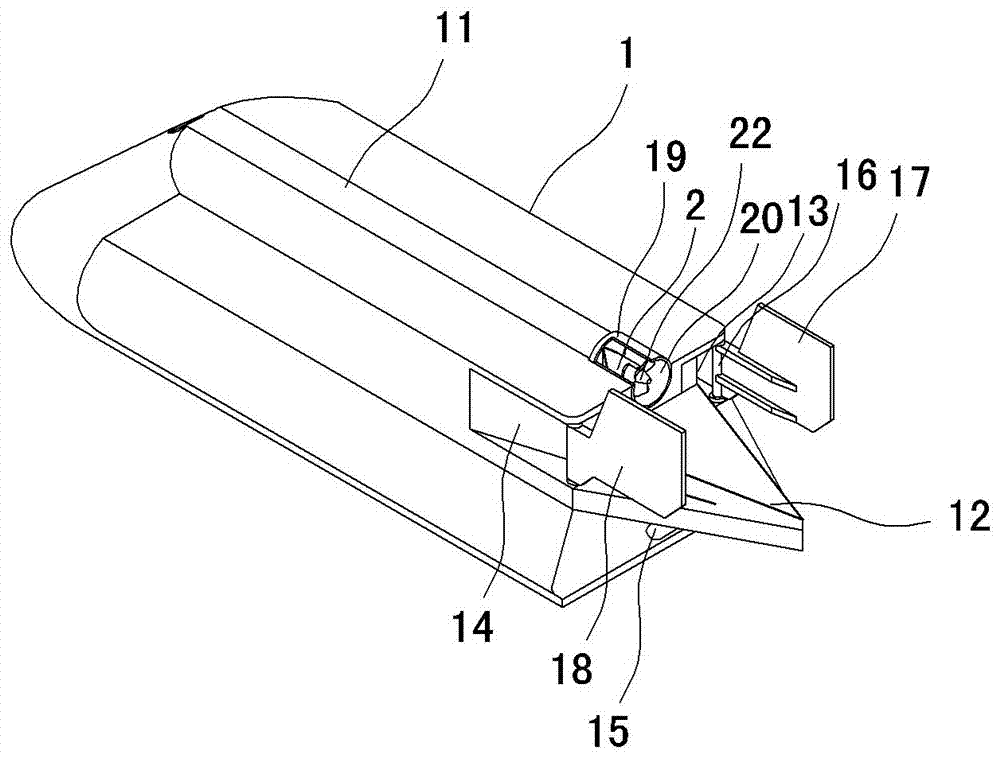

[0016] Embodiment two, such as image 3 , Figure 4 As shown, the difference from the first embodiment is that the propeller 2 is only provided with a rear propeller 22 towards the rear of the hull 1 .

[0017] Technical effect of the present invention:

[0018] 1. Since the ship is equipped with a vortex breaker 12 with a wide front and a sharp rear, the water flow can flow down when the ship sails forward, and no vortex phenomenon can be formed at the tail of the hull, which means that the ship cuts off the existing ship tail. Part of the eddy current is equivalent to cutting off part of the eddy current resistance when sailing forward, thereby improving the efficiency of the ship when sailing forward.

[0019] 2. When the ship is sailing forward, since the left and right oblique water tanks 13 and 14 are respectively provided on both sides of the stern of the hull, the two parallel water tanks can reduce the cross-sectional area of the hull stern, which is equivalent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com