Method of synthesizing methyl acetate through acetylene carbonylation

A technology for the synthesis of methyl acrylate, which is applied in chemical instruments and methods, carbon monoxide or formate reaction preparation, organic compound/hydride/coordination complex catalysts, etc., can solve problems affecting industrial applications and homogeneous catalysts Difficult to recycle and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

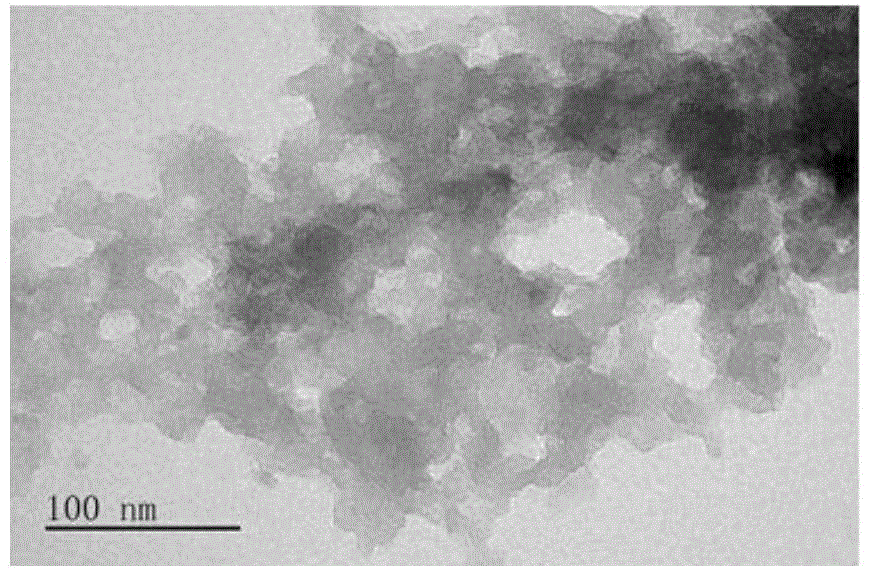

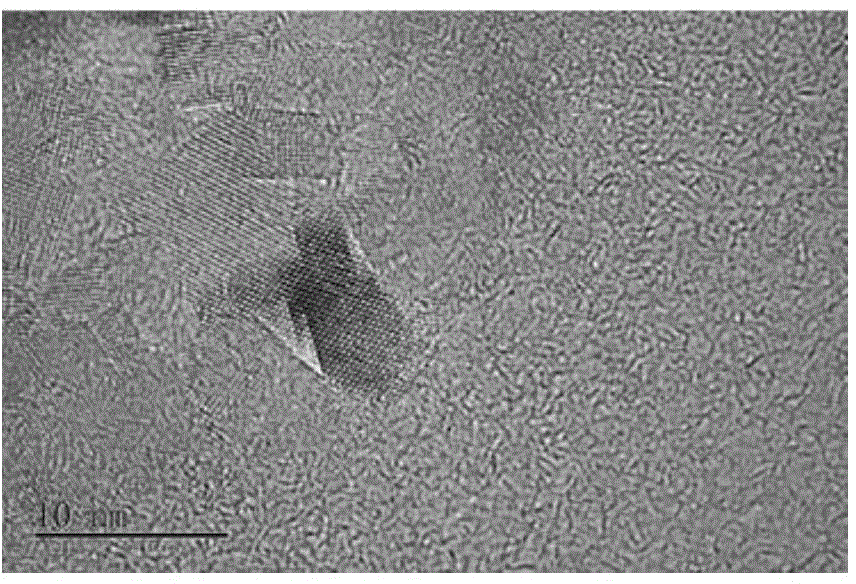

Image

Examples

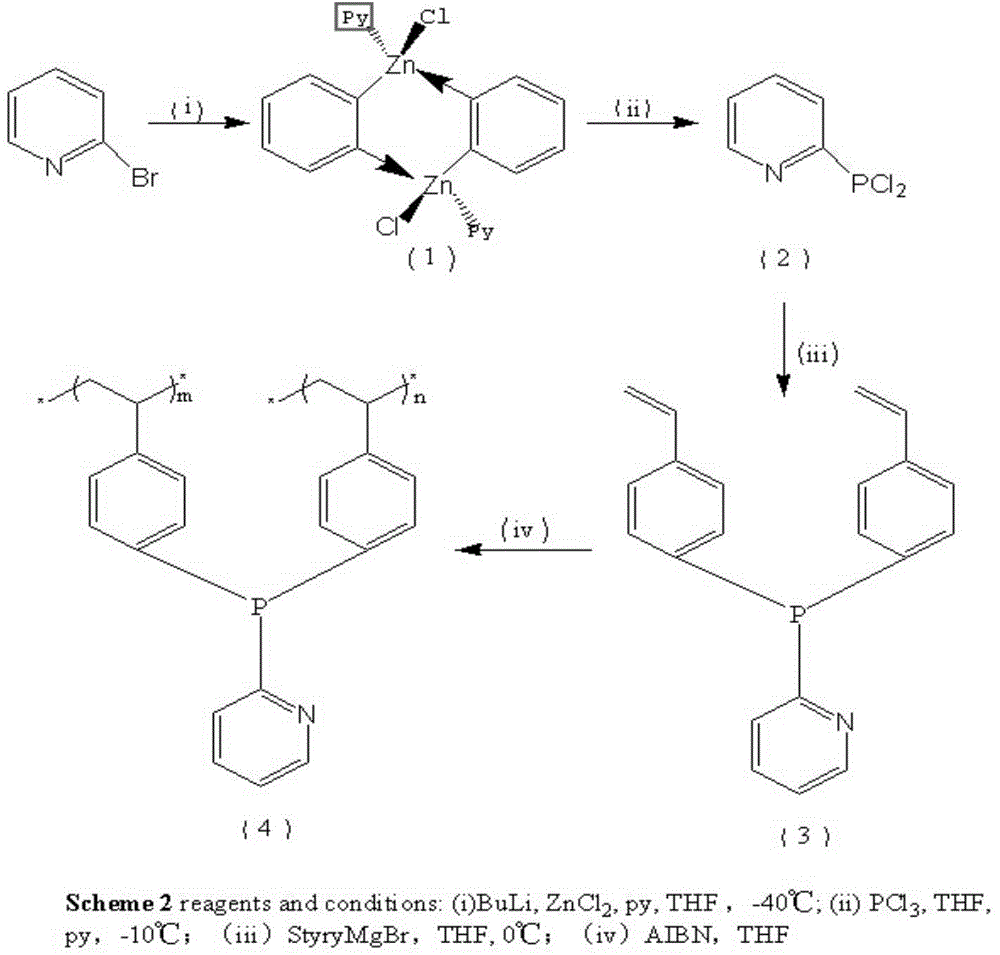

Embodiment 1

[0020] N-PPOL preparation method: In a liquid nitrogen bath and a nitrogen atmosphere, add 45ml of tetrahydrofuran, 0.12mol of n-butyllithium, 0.1mol of o-bromopyridine, 0.135mol of ZnCl 2 , 45ml pyridine, 90ml tetrahydrofuran, and react at room temperature for 14h. Pour out the liquid in the bottle under nitrogen protection, then add 60ml of pyridine, 180ml of tetrahydrofuran, and 0.12mol of PCl3 solution (dissolved in 60ml of pyridine and 60ml of tetrahydrofuran) successively under the condition of a liquid nitrogen bath, and then react at room temperature for 26h (named as reaction Liquid 1). In a liquid nitrogen bath and a nitrogen atmosphere, add 0.22mol (5.4g) of magnesium chips, 35ml of tetrahydrofuran, and 36.6g (0.2mol) of p-bromostyrene to another 1L three-necked round-bottomed flask with a magnetic stirring bar. (named as reaction solution 2). After the reaction solution 1 was filtered, it was added to the reaction solution 2 in a liquid nitrogen bath and a nitro...

Embodiment 2

[0023] Tetrahydrofuran was used instead of acetone as the solvent, and other conditions were the same as in Example 1.

Embodiment 3

[0025] Adopt normal hexane to replace acetone as solvent, other conditions are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com