Low-viscosity heat conducting silicone grease and preparation method thereof

A heat-conducting silicone grease and low-viscosity technology, which is applied in the field of thermal interface materials for electronic components, can solve the problems of poor surface wettability of heat-conducting silicone grease, unfavorable heat dissipation of electronic devices, and increased interface thermal resistance, so that it is not easy to settle and seep oil, eliminate interface defects, and reduce viscosity

Inactive Publication Date: 2016-07-13

苏州柯仕达电子材料有限公司

View PDF3 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

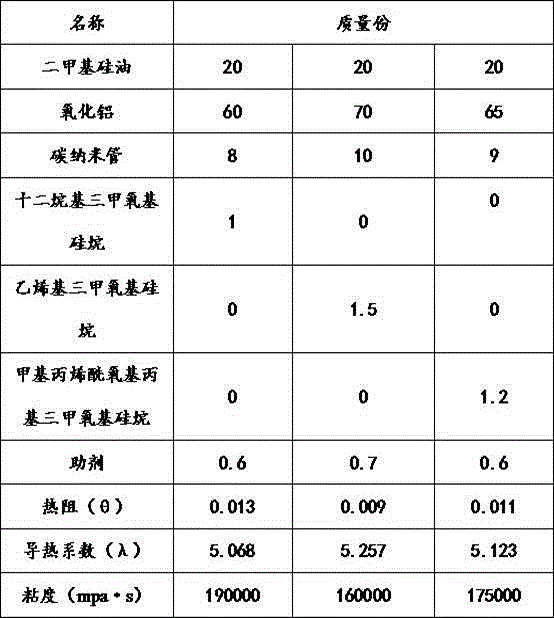

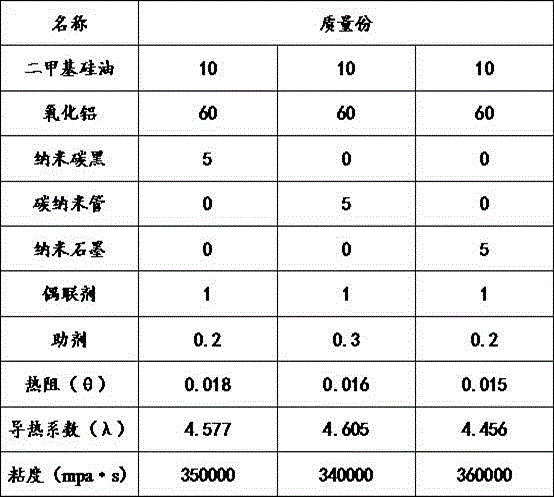

The thermally conductive silicone grease obtained by this method is a thermally conductive silicone grease product with high thermal conductivity, insulation and low contact thermal resistance. Adding a coupling agent can reduce the viscosity of the system, but the viscosity of the thermally conductive silicone grease obtained after mixing is close to 350,000 centipoise, the viscosity is still very high, and the surface wettability of thermal conductive silicone grease is poor, resulting in an increase in interface thermal resistance and poor overall thermal conductivity, which is not conducive to heat dissipation between electronic devices

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] The specific implementation process of the present invention will be described in further detail below in conjunction with the examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses low-viscosity heat conducting silicone grease. Composition of the low-viscosity heat conducting silicone grease comprises components of dimethyl silicone oil, heat conducting powder of class I, heat conducting powder of class II, a coupling agent and an auxiliary. A preparation method of the low-viscosity heat conducting silicone grease comprises steps as follows: step 1, the dimethyl silicone oil, the coupling agent and the auxiliary are added to a double-planet stirring machine to be mixed uniformly; step 2, the heat conducting powder of class II is added to a mixed liquid obtained in the step 1 and mixed uniformly; step 3, the heat conducting powder of the class I is added to a mixed liquid obtained in the step 2 and mixed uniformly; step 4, a mixed liquid obtained in the step 3 is sufficiently stirred and subjected to vacuum pumping and defoaming. The heat conducting silicone grease produced with the method has the characteristics of low viscosity, high heat conduction coefficient, low probability of sedimentation, low permeability, good long-term stability and the like.

Description

technical field [0001] The invention relates to a thermal interface material for electronic components, in particular to a low-viscosity heat-conducting silicone grease and a preparation method thereof. Background technique [0002] Thermally conductive silicone grease, also known as heat dissipation paste, is a paste heat dissipation material containing silicone oil. Due to the limitations of the manufacturing process and clamping method, there is always a small gap between the components and the heat sink, and the gap is filled with air, and air is a poor conductor of heat. The thermal conductivity of air is very low, which seriously affects the electronic components. the overall cooling effect. Filling the thermal conductive silicone grease in the gap between the components and the heat sink can ensure the close contact between the components and the heat sink, increase the contact area, improve the heat transfer efficiency, and quickly and evenly spread the heat generat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L83/04C08K3/22C08K3/28C08K3/38C08K3/04C08K7/24C08K5/5419C08K5/5425C08K5/5415

CPCC08L83/04C08K3/04C08K3/22C08K3/28C08K3/38C08K5/5415C08K5/5419C08K5/5425C08K7/24C08K2003/2227C08K2003/2296C08K2003/282C08K2003/385C08L2203/20

Inventor 李春方李成春倪丹丹曾域

Owner 苏州柯仕达电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com