Low-temperature extracted snake oil and method for deodorizing and de-coloring snake oil

A snake oil and low temperature technology, applied in the field of animal oil extraction, can solve the problems of snake oil active ingredient destruction, unpleasant odor or fishy smell, and restrictions on the widespread use of snake oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

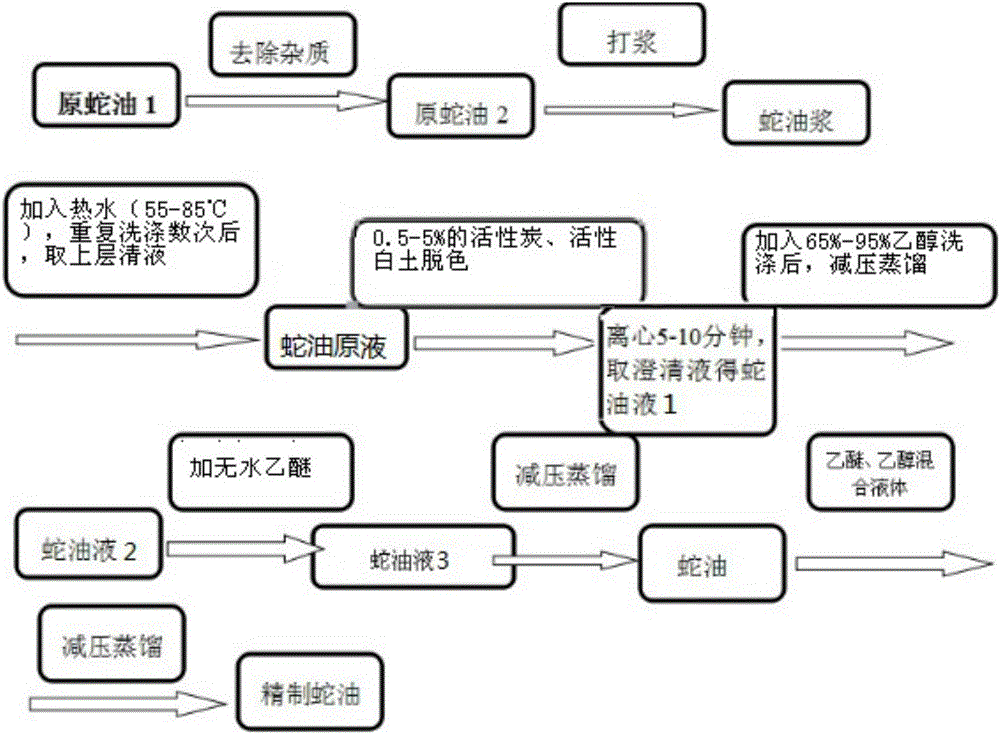

[0023] A method for extracting snake oil at low temperature and carrying out deodorization and decolorization of snake oil, comprising the following steps:

[0024] 1. Remove the impurities in the raw snake oil;

[0025] Two, beating is carried out to obtain snake oil slurry;

[0026] 3. Add hot water at 55°C to the snake oil slurry, and after repeated washing for 3 times, take the above clarified liquid to obtain the snake oil stock solution;

[0027] 4. After adding 0.5% active carbon and activated clay that respectively account for the weight of the snake oil stock solution in the snake oil stock solution, reflux at a temperature of 50°C for 30 minutes to decolorize, then centrifuge at a speed of 6000r / min for 5 minutes, and take the clear liquid to obtain the first a snake oil;

[0028] Five, adding concentration in the first snake oil liquid is the ethanol of 80%, gets clarified liquid, decompression distillation obtains the second snake oil liquid;

[0029] 6. Add anh...

Embodiment 2

[0033] 1. Remove the impurities in the raw snake oil;

[0034] Two, beating is carried out to obtain snake oil slurry;

[0035] 3. Add hot water at 75°C to the snake oil slurry, and after repeated washing once, take the above clarified liquid to obtain the snake oil stock solution;

[0036] 4. After adding activated carbon and activated clay that each account for 1% of the weight of the snake oil stock solution in the snake oil stock solution, reflux at a temperature of 60°C for 10 minutes to decolorize, then centrifuge at a speed of 7000r / min for 8 minutes, and take the clear liquid to obtain the first a snake oil;

[0037] Five, adding concentration in the first snake oil liquid is the ethanol of 65%, gets clarified liquid, decompression distillation obtains the second snake oil liquid;

[0038] 6. Add anhydrous ether to the second snake oil to obtain the third snake oil;

[0039] Seven, carry out decompression distillation to the 3rd snake oil liquid and obtain snake oil...

Embodiment 3

[0042] 1. Remove the impurities in the raw snake oil;

[0043] Two, beating is carried out to obtain snake oil slurry;

[0044] 3. Add hot water at 85°C to the snake oil slurry, and after repeated washing twice, take the above clarified liquid to obtain the snake oil stock solution;

[0045] Four, in the snake oil stock solution, after adding gac and activated clay that each account for 2% of the snake oil stock solution weight, reflux at a temperature of 80°C for 60 minutes to decolorize, then centrifuge at a speed of 5000r / min for 5 minutes, and take the clear liquid to obtain first snake oil;

[0046] 5. Adding concentration to the first snake oil liquid is 75% ethanol, taking the clarified liquid, and decompressing distillation to obtain the second snake oil liquid;

[0047] 6. Add anhydrous ether to the second snake oil to obtain the third snake oil;

[0048] Seven, carry out decompression distillation to the 3rd snake oil liquid and obtain snake oil;

[0049] 8. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com