Multilayer oblique slotted self anti-buckling steel plate shear wall and manufacturing method thereof

A technology of steel plate shear wall and multi-layer steel plate, which is applied in the direction of wall, earthquake resistance, building, etc., to achieve the effect of simple structure, high construction efficiency and stable energy dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

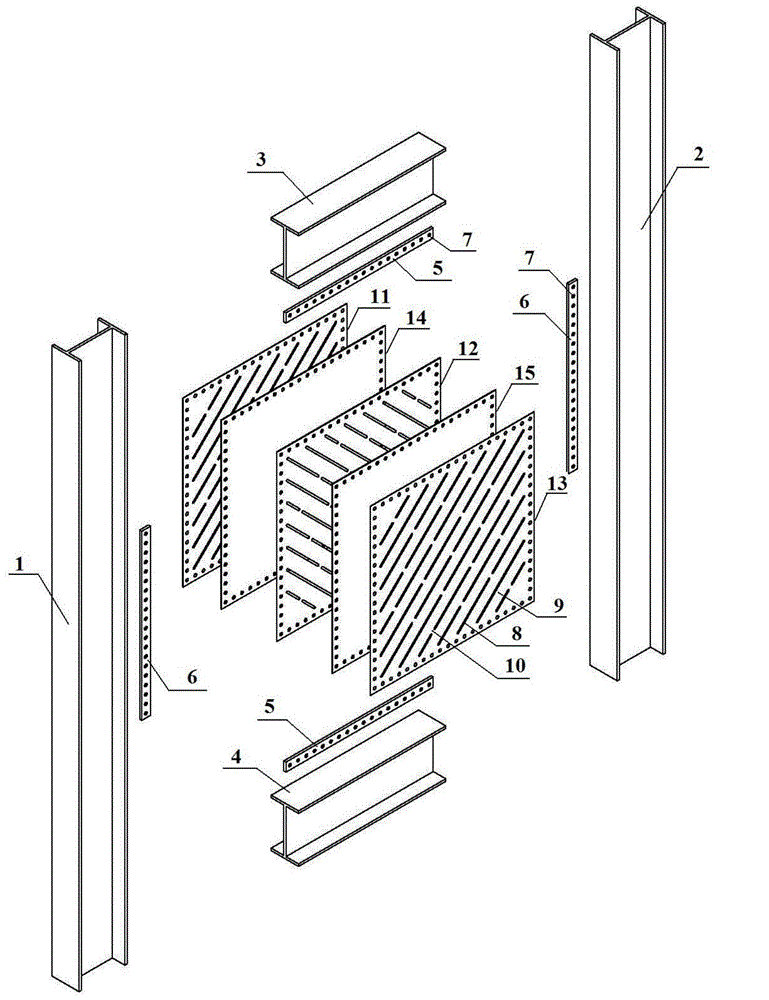

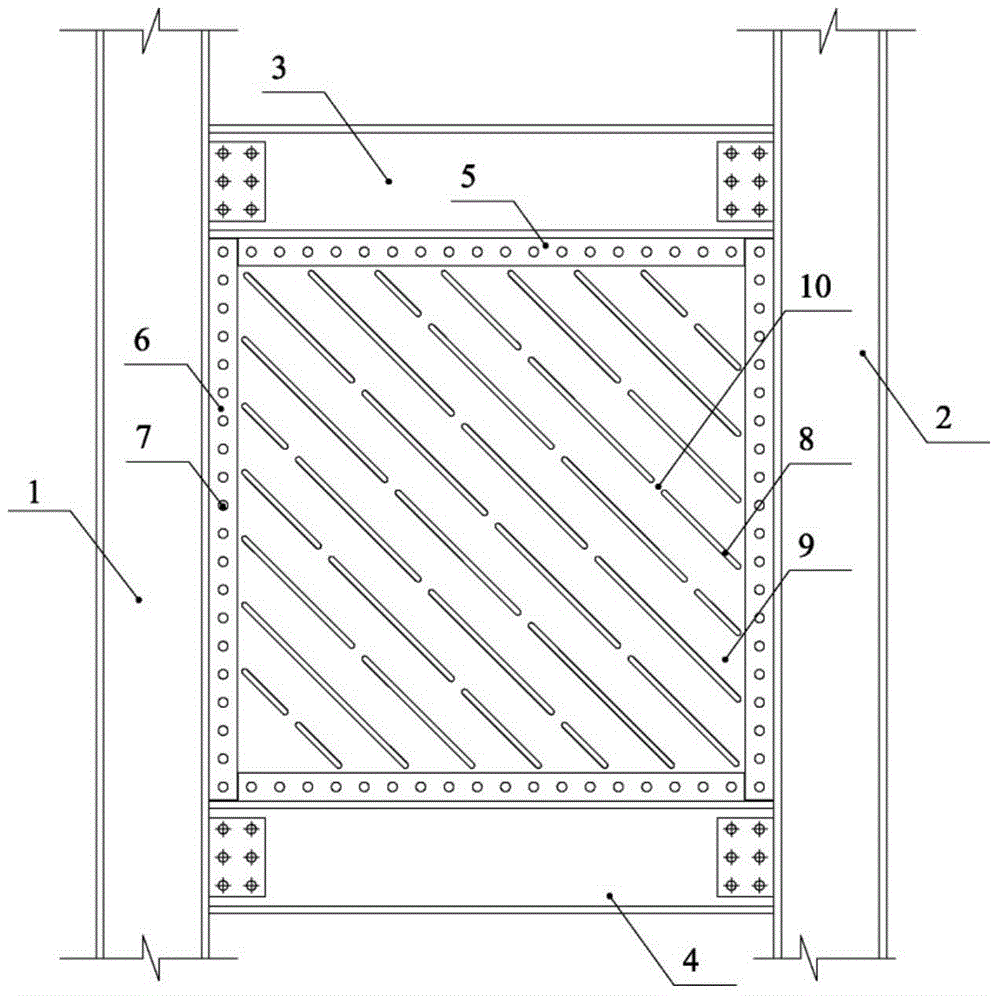

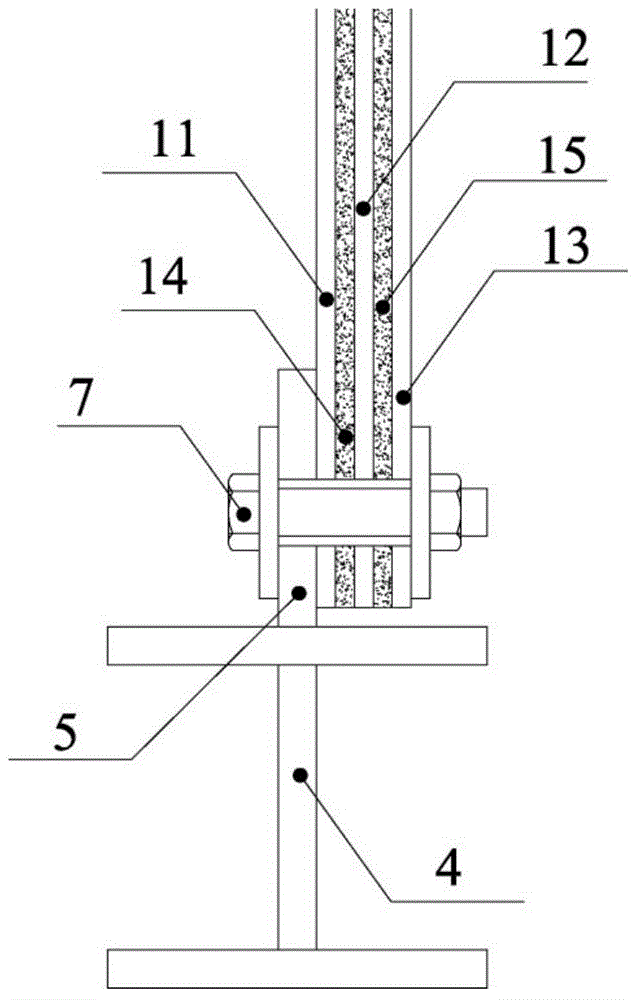

[0031] like Figure 1-2 As shown, a self-buckling steel plate shear wall with multi-layer oblique grooves is characterized in that it includes multi-layer obliquely grooved steel plates, and the oblique grooves of each layer of steel plates have the same groove direction, adjacent The oblique grooves of the two layers of steel plates are in opposite directions; the two adjacent layers of steel plates are bonded by damping rubber; the edges of the multi-layer steel plates are connected to the frame; the damping rubber participates in dissipating seismic energy.

[0032] Under the action of reciprocating horizontal earthquake loads, the oblique slabs in the same direction are in the state of unidirectional tension or unidirectional compression respectively. Using the tension stiffness of a certain layer of slanted slabs in tension, the The strap provides out-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com