Steel body PDC (Polycrystalline Diamond Compact) directional bit for directional drilling under coal mine

A technology of directional drilling and directional drill bits, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc. It can solve the problems of high cutting resistance, PDC cutter positioning accuracy needs to be improved, and high production cost, and achieves strong branching ability and realizes Effects of repeated use and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

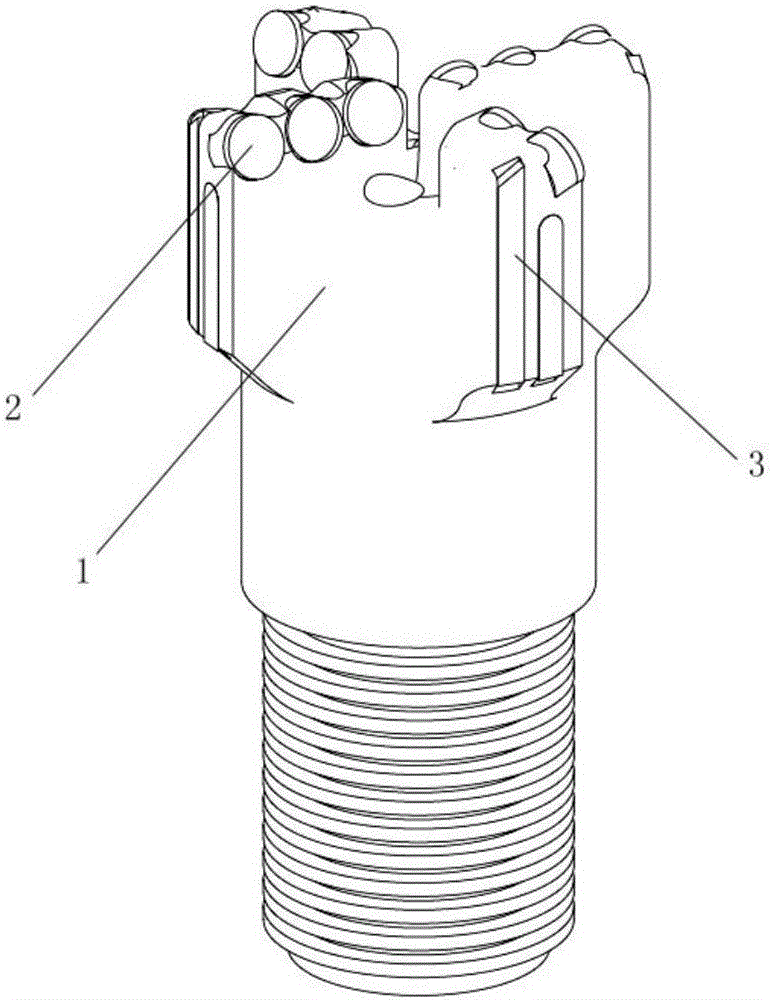

[0022] Such as figure 1 As shown, a steel body type PDC directional drill bit for directional drilling in underground coal mines includes a drill bit steel body 1, four blades and diamond-impregnated gage blocks 3,

[0023] The outer surface of one end of the drill bit steel body 1 is provided with threads,

[0024] The bottom surface of the other end of the drill bit steel body 1 is welded with four blades, and the outermost side of the blades is welded with PDC cutting teeth 2, and the PDC cutting teeth 2 are distributed in a scraper pattern.

[0025] The outer wall of the other end of the drill steel body 1 is evenly welded with a plurality of diamond-impregnated gauge blocks 3 , and the multiple diamond-impregnated gauge blocks 3 form a gauge surface, which is perpendicular to the PDC cutting teeth 2 .

[0026] Further, the steel body 1 of the drill bit is made of alloy steel.

[0027] Further, the center distances of the outermost PDC cutting teeth 2 are equal.

[0028...

specific Embodiment 2

[0032] Roughly the same as specific embodiment 1, the difference only lies in:

[0033] A steel body type PDC directional drill bit for directional drilling in coal mines includes three blades;

[0034] The height of the outgoing edge of the PDC cutter 2 is 2mm;

[0035] The diamond concentration of the diamond-impregnated gauge block 3 is 120%.

specific Embodiment 3

[0036] Roughly the same as specific embodiment 1, the difference only lies in:

[0037] A steel body type PDC directional drill bit for directional drilling in coal mines includes six blades;

[0038] The height of the outgoing edge of the PDC cutter 2 is 1.5 mm;

[0039] The diamond concentration of the diamond-impregnated gauge block 3 is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com