A wet multi-disc pressure loss brake

A brake, wet technology, applied in the direction of the brake type, axial brake, brake parts, etc., can solve the problems of spring preload elastic force can not be adjusted, static friction plate and brake shell stuck, machining requirements are relatively high, etc., to achieve Reduce the difficulty of machining, simplify the hydraulic system, and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

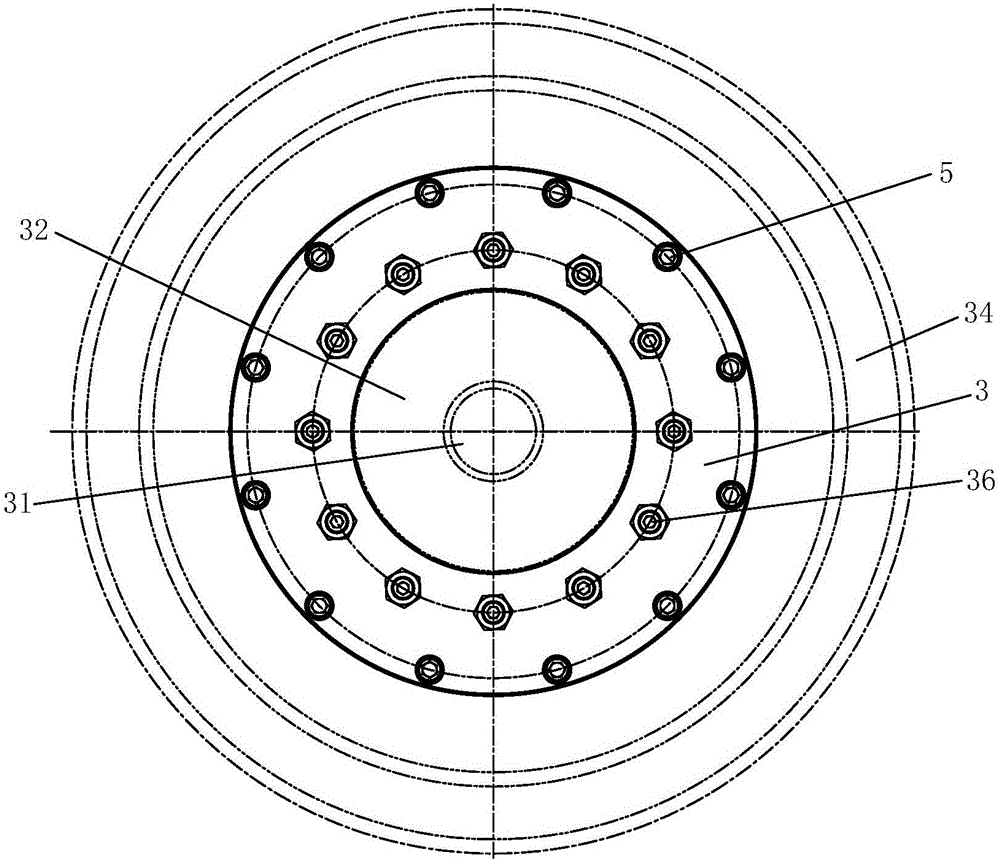

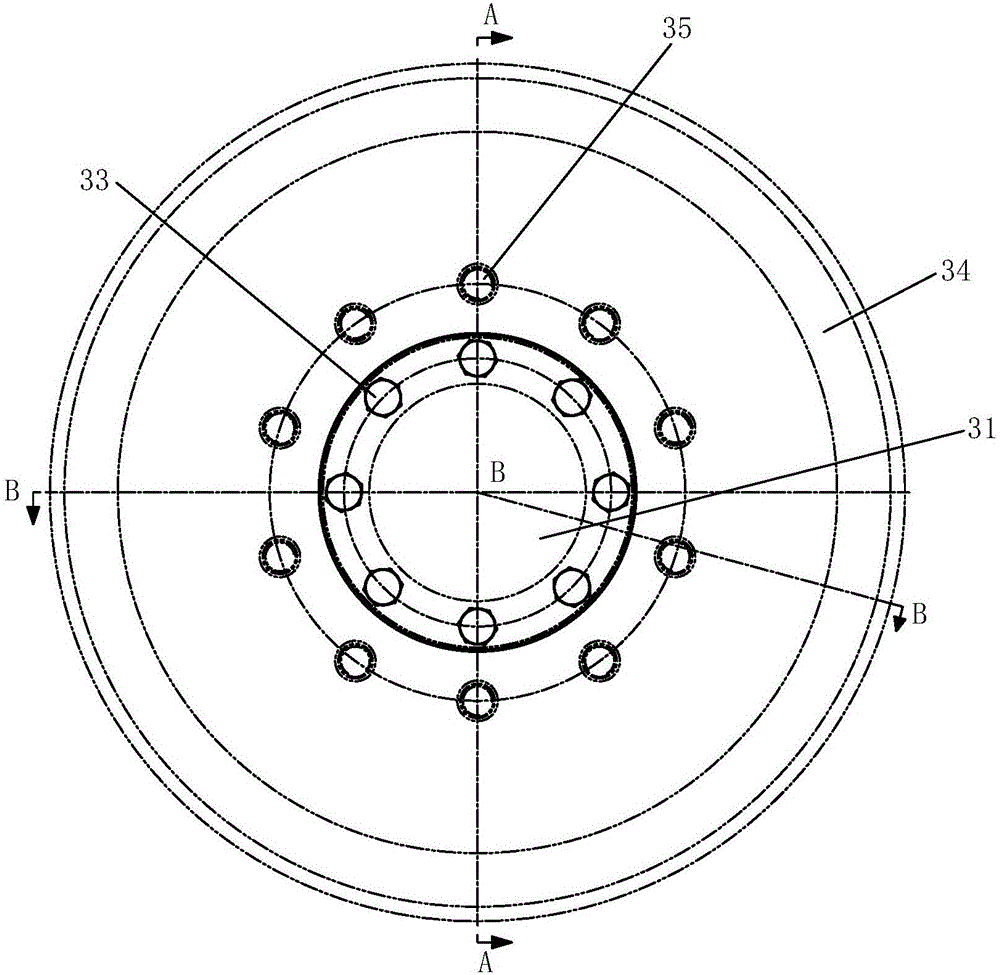

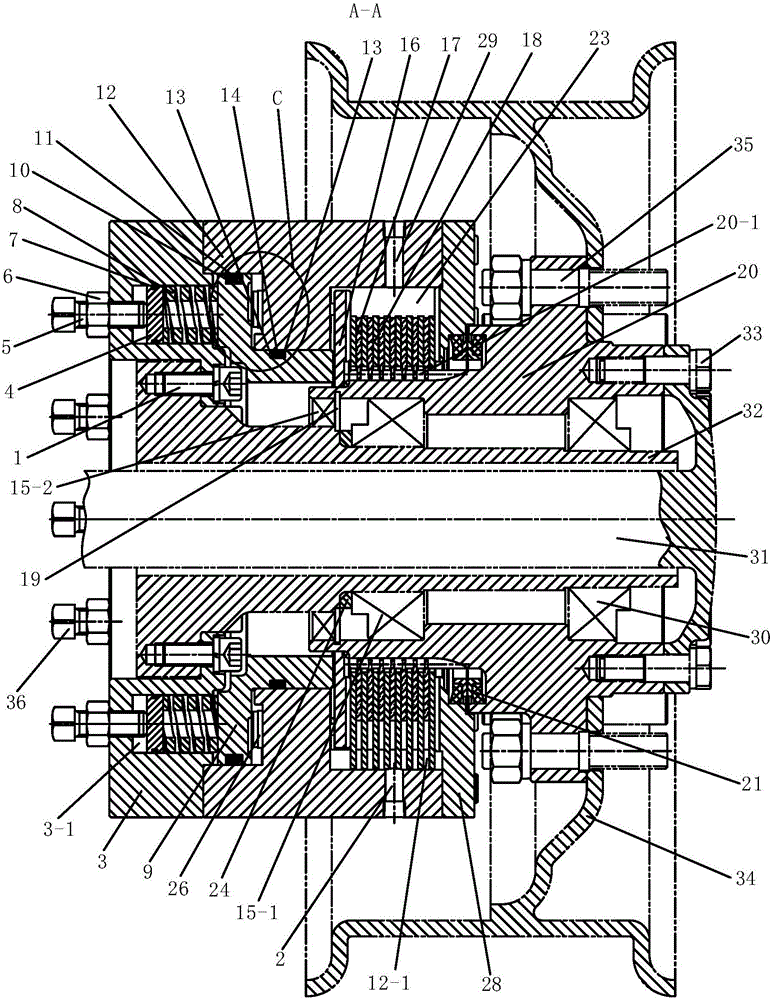

[0048] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the present invention includes a fixed part and a rotating part, and the rotating part includes a spline shaft 20 and a rotating shaft 31, and the rotating shaft 31 passes through the spline shaft 20 and is fixedly connected with the spline shaft 20; the fixed part Including installation shell 3, brake shell 12, brake piston 9, baffle plate 28 and bearing sleeve 32, said brake shell 12 is arranged between installation shell 3 and baffle plate 28, said installation shell 3, brake shell 12 and the baffle plate 28 are fixed together, the brake piston 9 is set in the brake housing 12, a brake chamber 26 is formed between the brake housing 12 and the brake piston 9, and the brake housing 12 A hydraulic oil port 25 communicating with the brake chamber 26 is opened on the top, and a plurality of installation chambers 3-1 are evenly opened around the circumference of the installation shell 3, and a pair of brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com