Temperature measurement alarming device for electrical equipment jointing clamp

A technology for electrical equipment and alarm devices, applied in the field of alarm devices, can solve the problems of large connection gap between steel-cored aluminum stranded wires and equipment clamps, accelerated oxidation and scaling of contact surfaces, and poor operating conditions, and achieves simple structure, The installation is firm and reliable, and the effect of normal operation is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

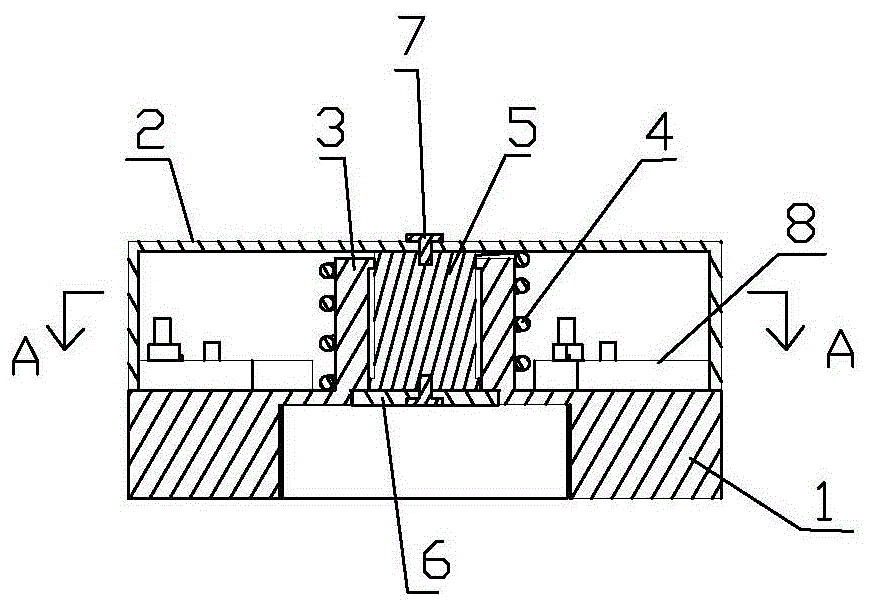

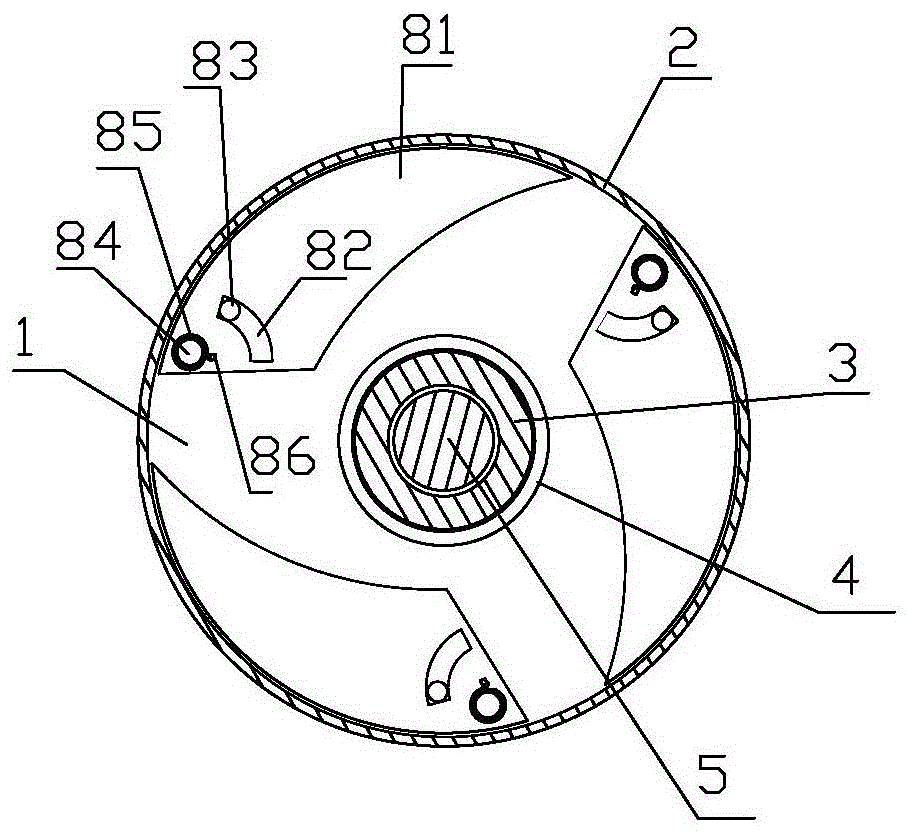

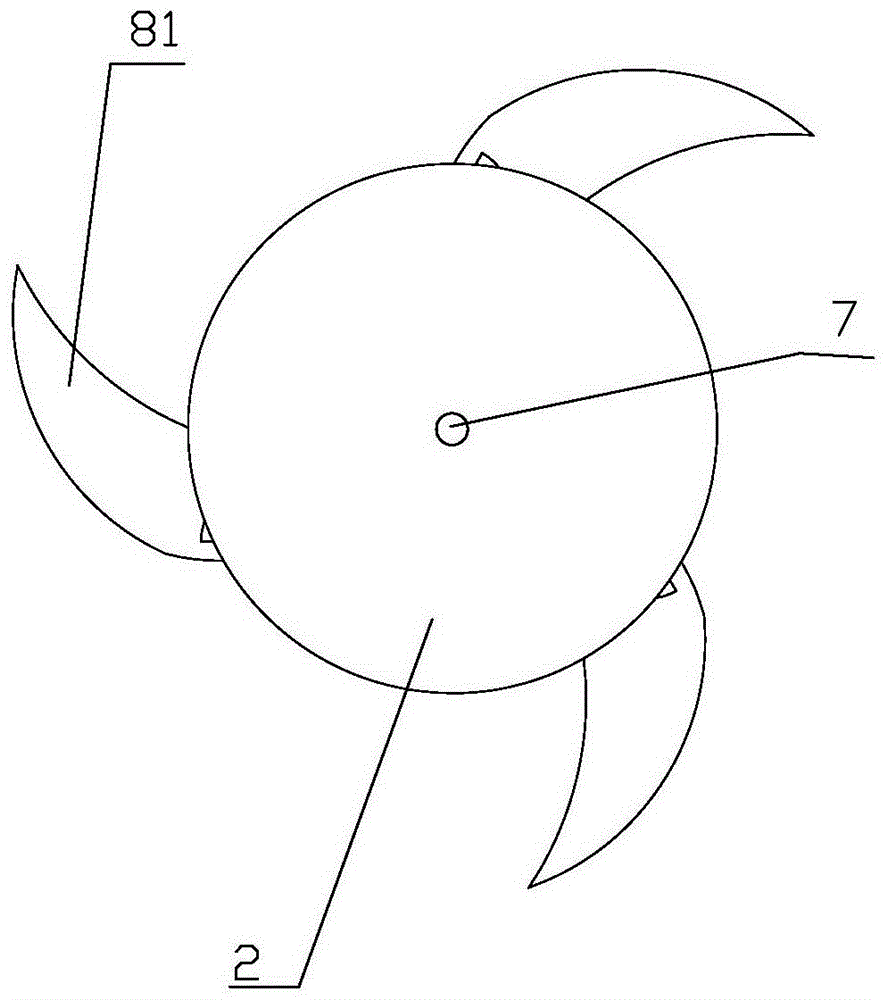

[0013] refer to figure 1 , figure 2 Make the invention. The temperature measurement and alarm device of the electrical equipment wiring clip includes a base 1 and an upper cover 2, the middle part of the base 1 is provided with a through hole, and the inner wall of the lower part of the through hole of the base 1 is provided with a screw thread suitable for the bolt, so that the base 1 is installed at the end of the bolt of the electrical equipment connection clamp, the upper cover 2 is set on the upper part of the base 1, and the lower end of the side wall of the upper cover 2 coincides with the upper plate surface of the base 1, and its feature is: the through hole of the base 1 The upper part is fixed with a sliding sleeve 3, and a sliding column 5 is arranged in the cavity of the sliding sleeve 3. The upper end of the sliding column 5 passes through the upper edge of the sliding sleeve 3 and is connected and fixed with the upper cover 2 through the screw 7. Between the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com