Apparatus and method for detecting rotor-side dynamic thermal parameter of medium-low-speed motor in real time

A low-speed motor, real-time detection technology, used in measuring devices, temperature measurement in motors, motor vehicles, etc., can solve the problem that real-time thermal detection of motor rotors cannot be performed, achieve real-time monitoring and fault prediction, improve motor efficiency, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the examples.

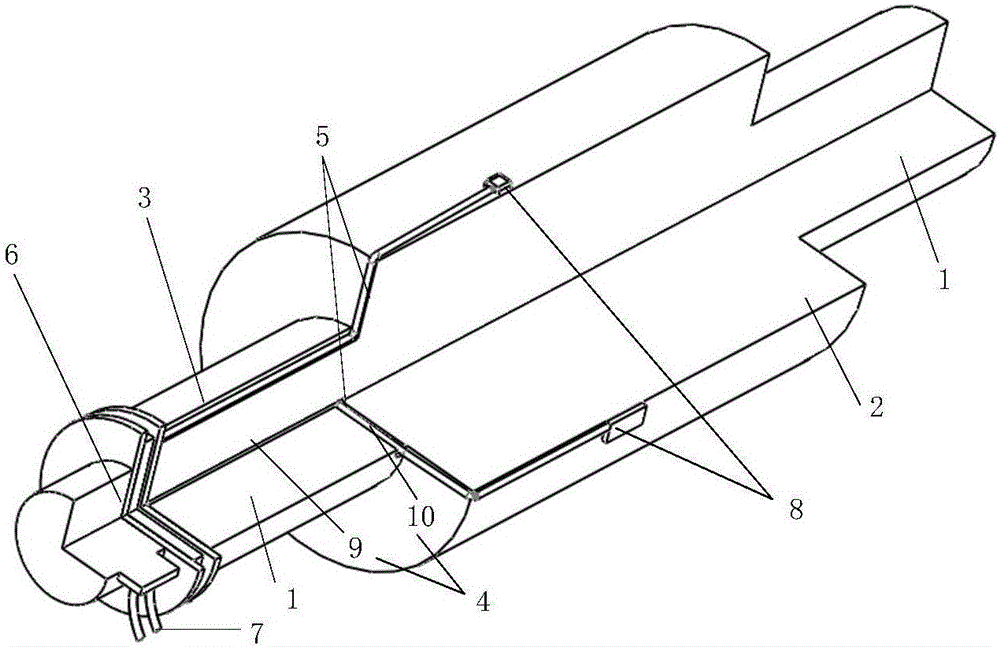

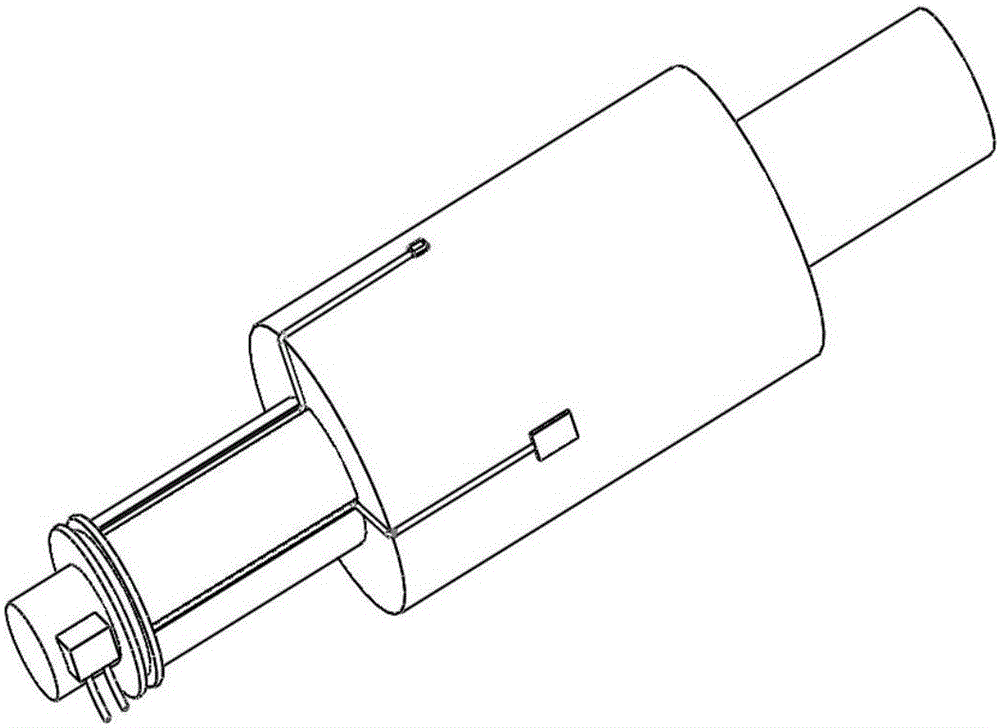

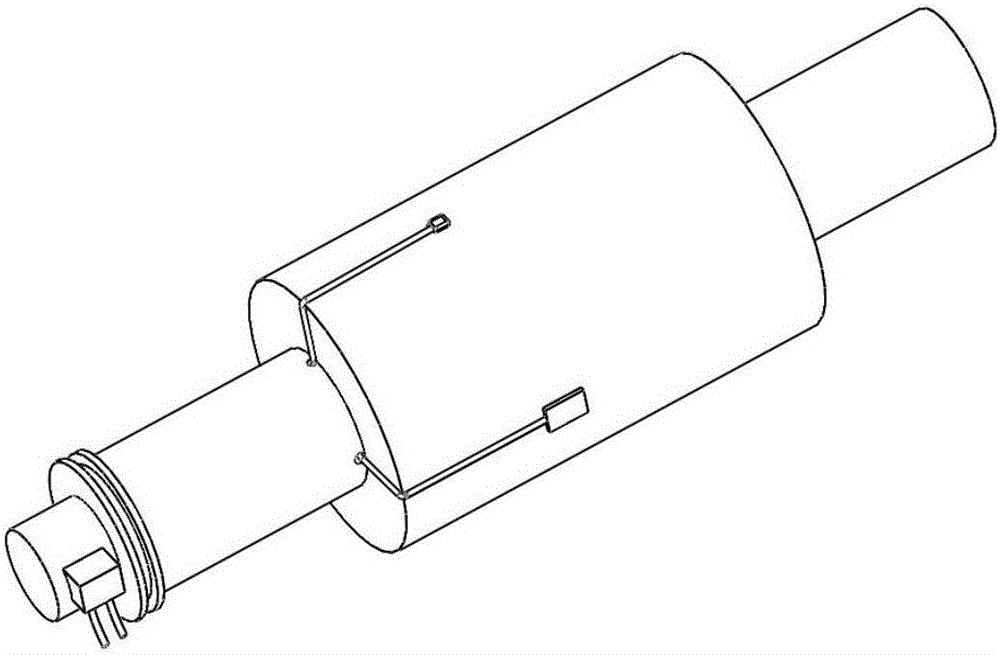

[0022] When the laboratory is measuring the temperature of the rotor side of a certain motor, the first thing to consider is the rotational speed. When the rotational speed is below 10000r / min, the method pointed out by the present invention can be used. Combining the material of the motor shaft and the laboratory technology, the motor adopts the method of punching a small hole in the middle of the shaft. Among them, the axial round hole 9 is opened from one end of the rotating shaft to the stator core, and the diameter of the small hole is 5mm, which can be determined according to the actual situation, and is proportional to the number of detection points and the gauge of the signal wire; the radial round hole 10 is from the iron core The rotating shaft at the cross section opens into the axial circular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com