TDI-CCD-based large-aperture long-focal length remote sensing camera distortion measurement device and measurement method

A remote sensing camera and measuring device technology, applied in the field of optical machinery, can solve problems such as the final image distortion correction residual, and achieve the effects of improving accuracy, saving money, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

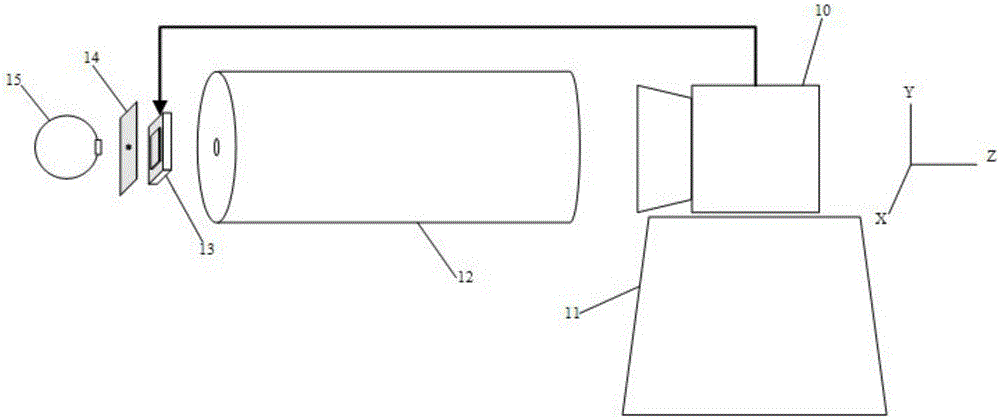

[0028] The present invention will be described in detail below with reference to the drawings and specific embodiments.

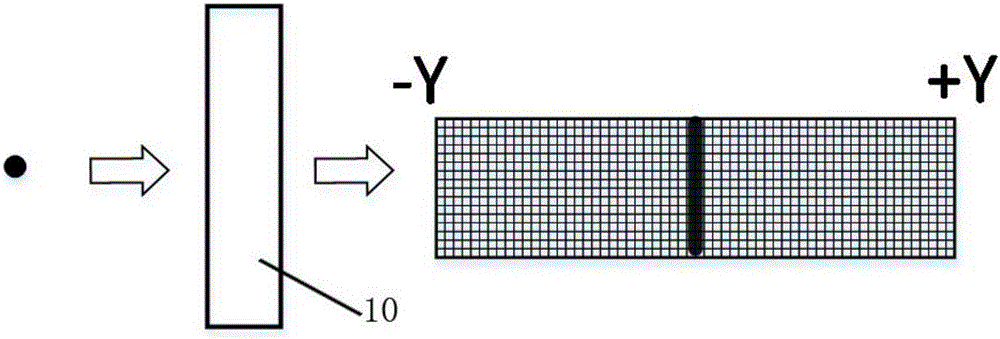

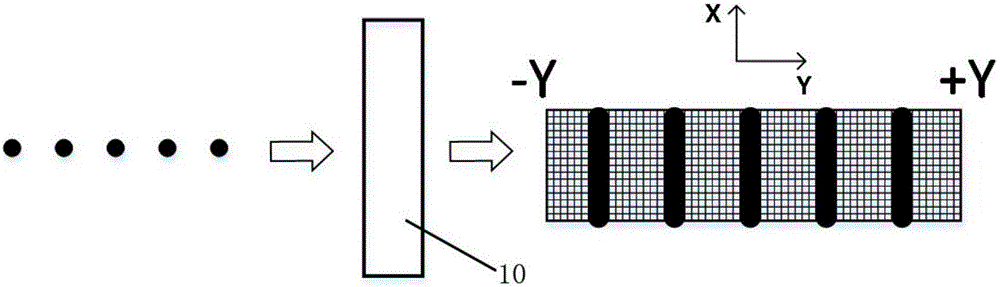

[0029] The camera based on the TDI-CCD large-aperture long focal length sensor is a type of line-scan camera. Its normal working mode is scanning, that is, there must be a certain relative movement between the camera and the imaged target during imaging, and the movement speed must be integrated with the imaging Match the time, otherwise there will be smear in the push sweep direction. When there is no relative movement between the imaged target and the camera, the imaging result is a vertical stripe parallel to the sweep direction, such as figure 2 .

[0030] When measuring the optical distortion of the camera in the normal working mode of the TDI-CCD large-aperture long-focus remote sensing camera, the parallel halo is used to simulate the target at infinity, and the star point target is maintained at a fixed position. Every time the two-dimensional turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com