Electronic frequency shift simulator for laser velocity measurement sensor

A laser speed measurement and sensor technology, applied in the testing/calibration of speed/acceleration/shock measurement equipment, instruments, measuring devices, etc., can solve the problem of difficult to find moving targets and test equipment, high precision requirements for landing navigation measurement, and speed measurement simulation Problems such as difficulty in device design, etc., to achieve the effect of small error, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

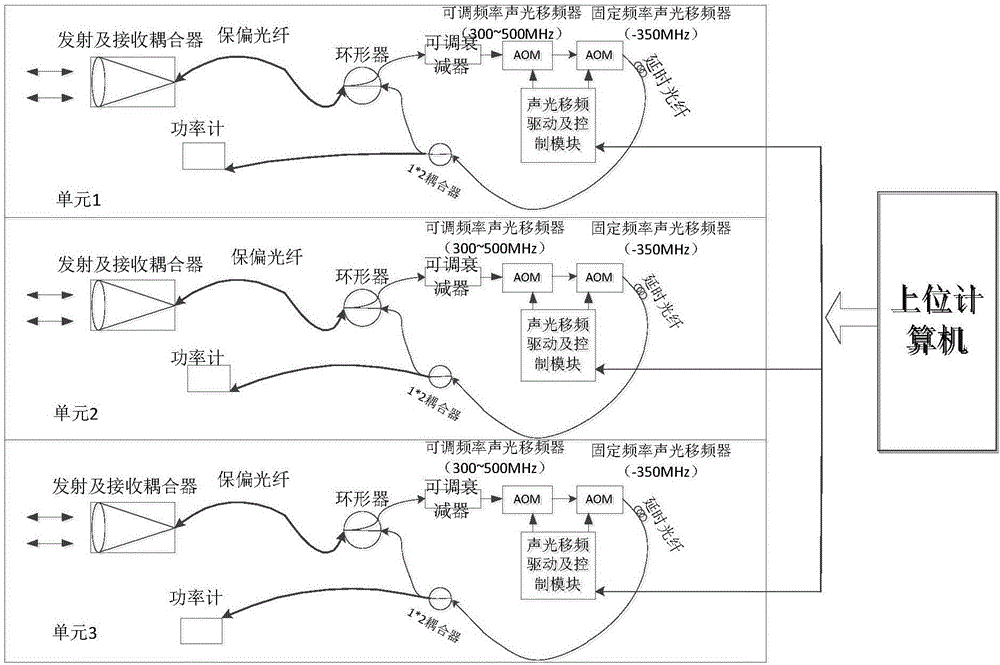

[0026] The present invention is composed of three analog channels, which respectively correspond to the three velocity vector channels of the laser speed measuring sensor. The hardware of the three channels is consistent. The following only describes one channel:

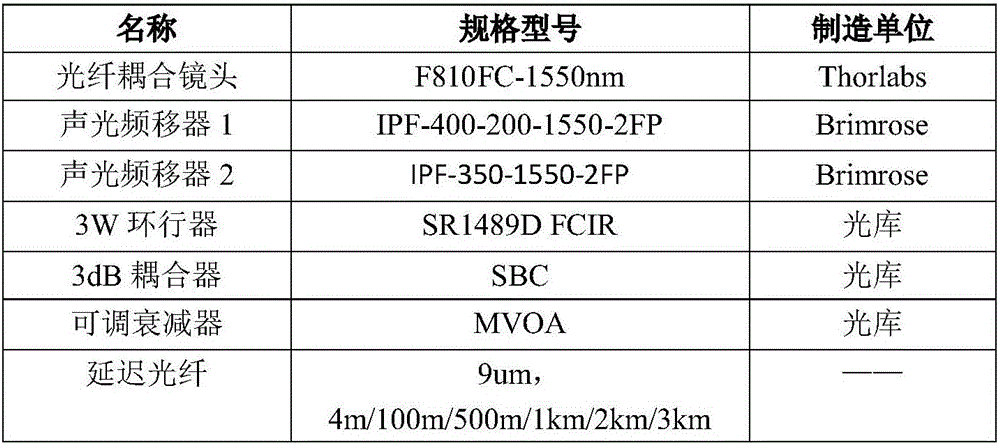

[0027] The transmitting and receiving modules consist of fiber couplers and single-mode polarization-maintaining fibers. The fiber optic coupler is F810FC-1550 from Thorlabs in the United States, with a focal length of 37.13 mm, a numerical aperture of 0.24, an entrance pupil of 8.91 mm, and a convergent spot diameter of 10.3 μm. The single-mode polarization-maintaining fiber adopts CorningPMFibersPI936 of the optical library, the core diameter is 9μm, and the accepted power is greater than 3W.

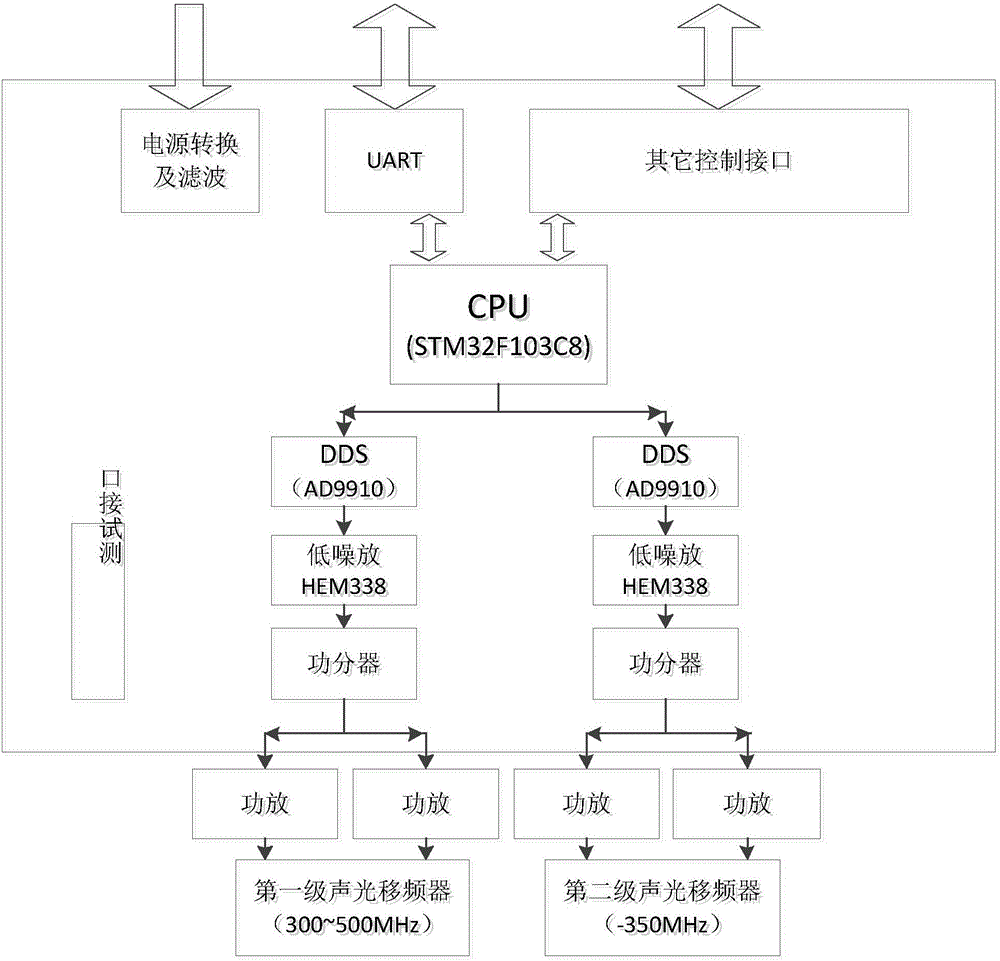

[0028] The electric control box includes an electronic frequency shift function modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com