PCB encoding identification method

A PCB board and coding technology, applied in the field of coding, can solve problems such as the difficulty of complete preservation of PCB board-related information, affect identification, classification and use, and fail to meet market requirements, and achieve easy implementation, promotion of informatization, and reduction of PCB area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

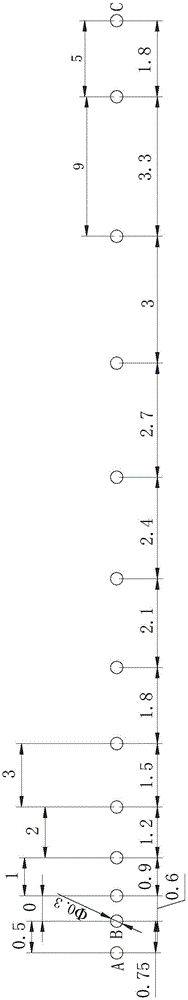

[0024] Such as figure 1 As shown, this embodiment proposes a method for coding and marking PCB boards. The method uses a punching device to process a plurality of through holes on the PCB board. The plurality of through holes are distributed in an array, and the distance between two adjacent through holes is Represents a single digit, and multiple digits are arranged in sequence to form a code. When decoding, image recognition equipment is used to collect multiple through holes, and the sequentially arranged digital code is obtained by measuring the distance between two adjacent through holes.

[0025] In this embodiment, a plurality of through holes are arranged in a one-dimensional array, and the through holes are circular holes, and the distance between the centers of two adjacent through holes minus the diameter of the through holes is used as the distance between two adjacent through holes. However, this is only a preferred embodiment of the present invention, and is not ...

Embodiment 2

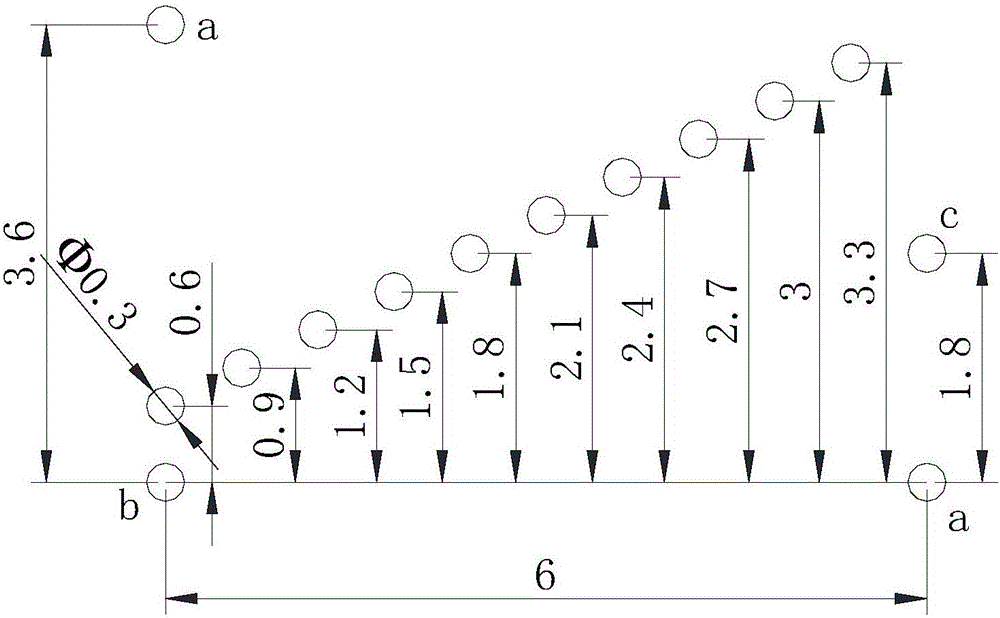

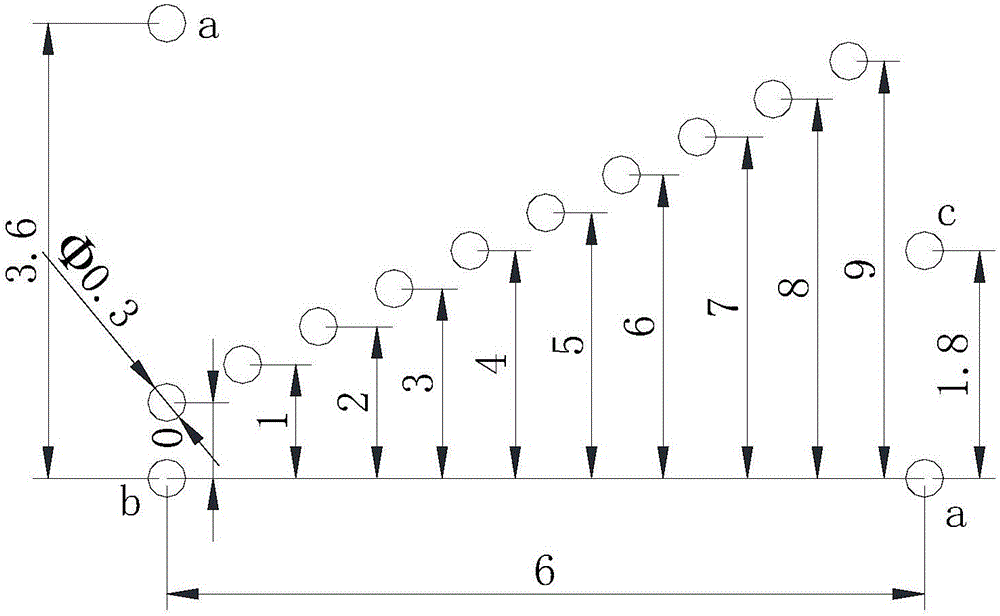

[0033] combine figure 2 and image 3 As shown, this embodiment proposes another array form, wherein a plurality of through holes are arranged in a two-dimensional array, each column in the two-dimensional array includes two through holes, and the distance between the two through holes Represents a single digit.

[0034] The code also includes an azimuth code, which is located before the valid code or on both sides of the valid code and the check code. For the two-dimensional hole distance marking method, three vertex holes can be punched on the edge of the first and last columns to mark the two-dimensional coding direction, and the right angle of the three holes is the starting point. For two-dimensional hole spacing coding, the two horizontal intervals represented by three vertex holes are 11 minimum units.

[0035] Please refer to figure 2 and image 3 , the application example is as follows: the diameter of the round hole is 0.3mm, the minimum spacing unit is 0.3mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com