Mineral carbonate looping reactor for ventilation air methane mitigation

A technology of carbonate minerals and reactors, which is applied in the direction of gas emission, mining equipment, chemical instruments and methods, etc., and can solve the problems of unrealistic commercial application, high material volume, low adsorption degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

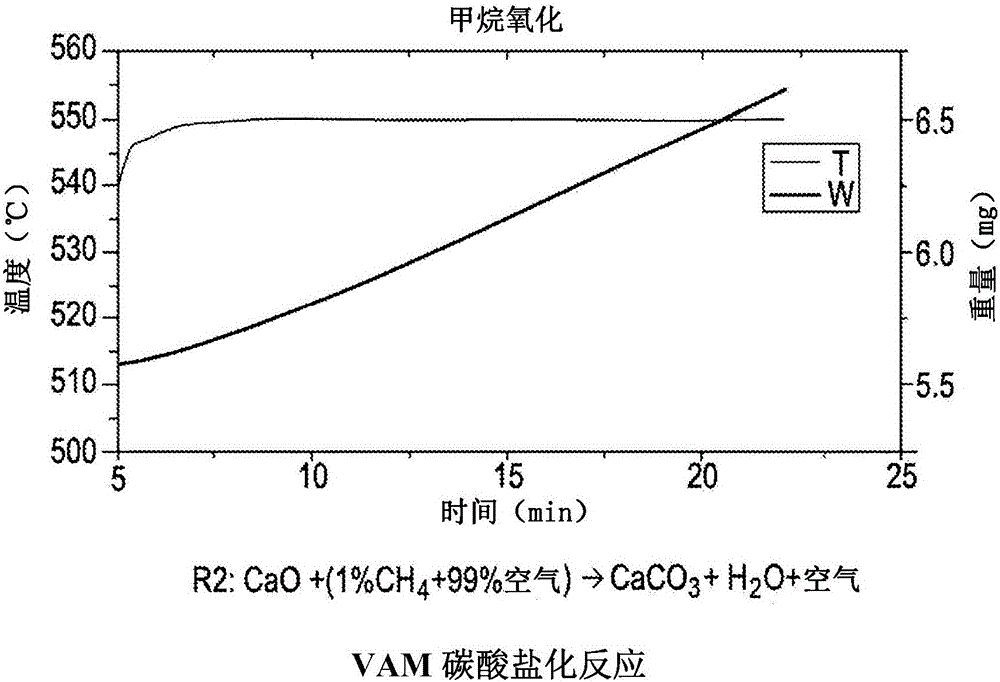

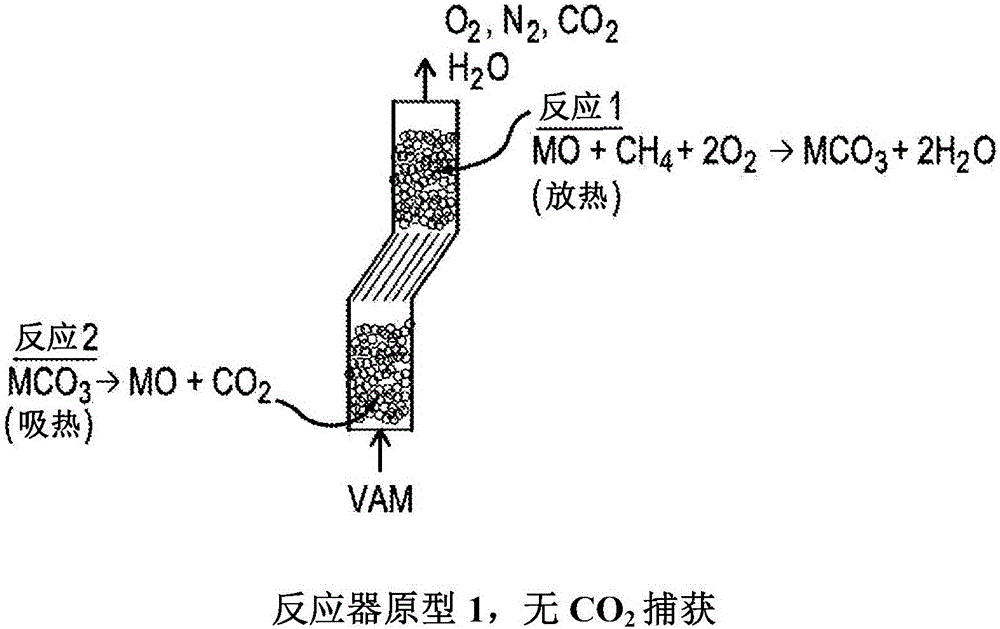

[0035] The present invention is a new VAM destruction technology, which adopts the technology called "carbonate mineral circulation reactor (MCLR)" or "rock dust circulation reactor (SDLR)". The invention can be operated at a lower cost due to the low operating temperature. Moreover, an advantage of the present invention is that by capturing the by-product CO 2 To further reduce emissions, but in the current VAM application or destruction technology, due to CO 2 Concentrations in the VAM exhaust flue gas stream are very low and thus are not captured. The MCLR / SDLR approach presented here can be illustrated by reactions 1 and 2 below.

[0036]

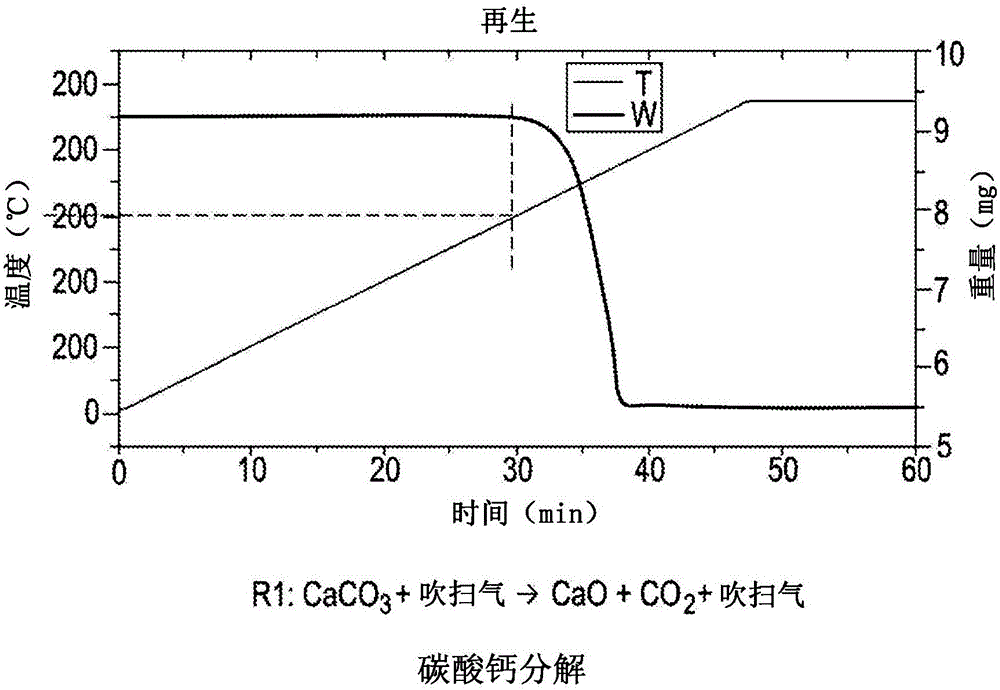

[0037] MCO 3 →MO+CO 2 (2)

[0038] Reaction 1 is called combustion + carbonation, where mineral / oxide minerals (MO) react with the VAM stream to form carbonate minerals. This reaction is exothermic and releases energy. The reaction has been found to proceed at temperatures below the autoignition temperature of methane. This m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com