A kind of air energy plant active substance extraction system

An extraction system and active substance technology, applied in the field of air energy plant active substance extraction system, can solve the problems of high equipment operation difficulty, high site requirements, low equipment integration, etc., to reduce operation difficulty and maintenance costs, and reduce site requirements. , the effect of reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

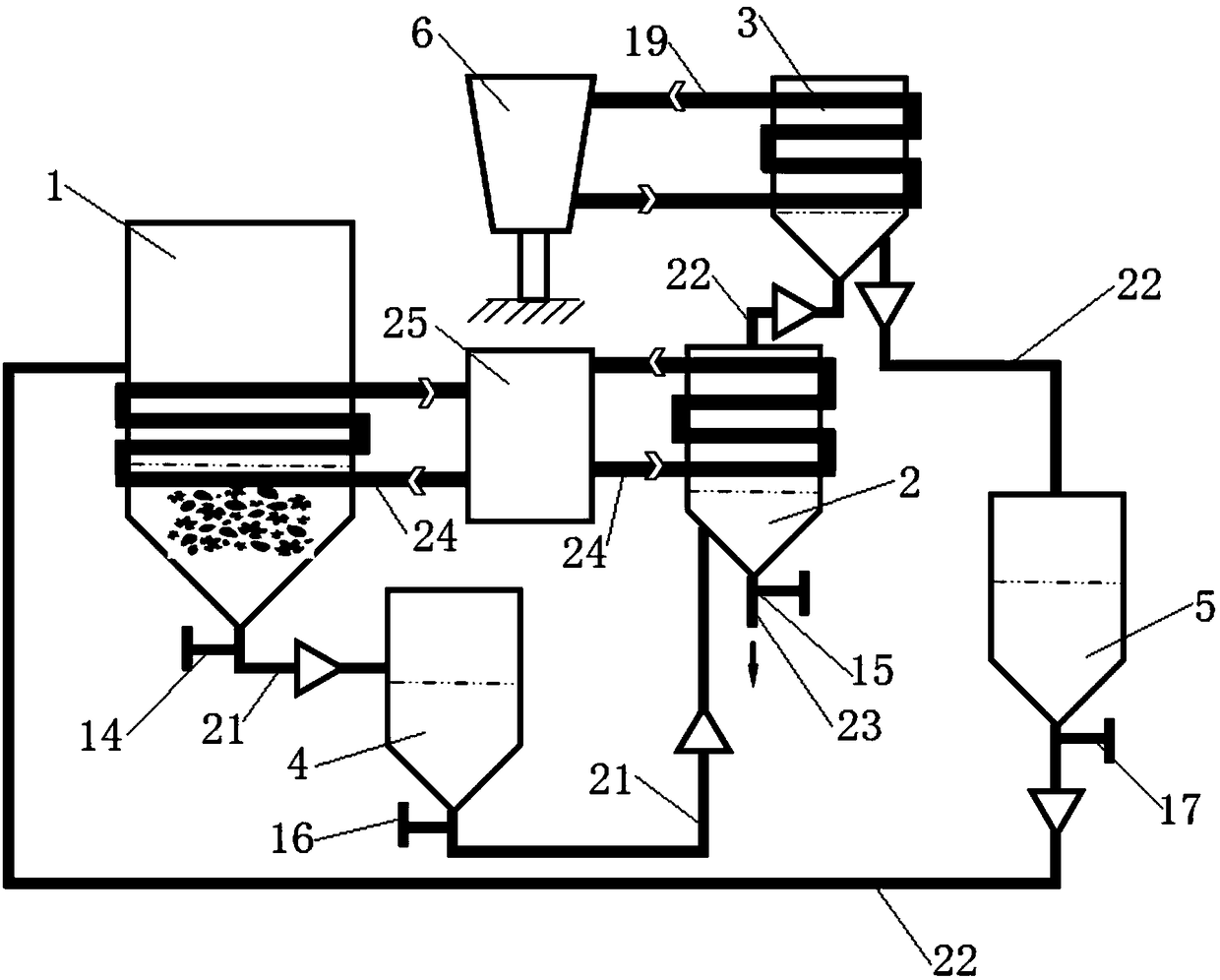

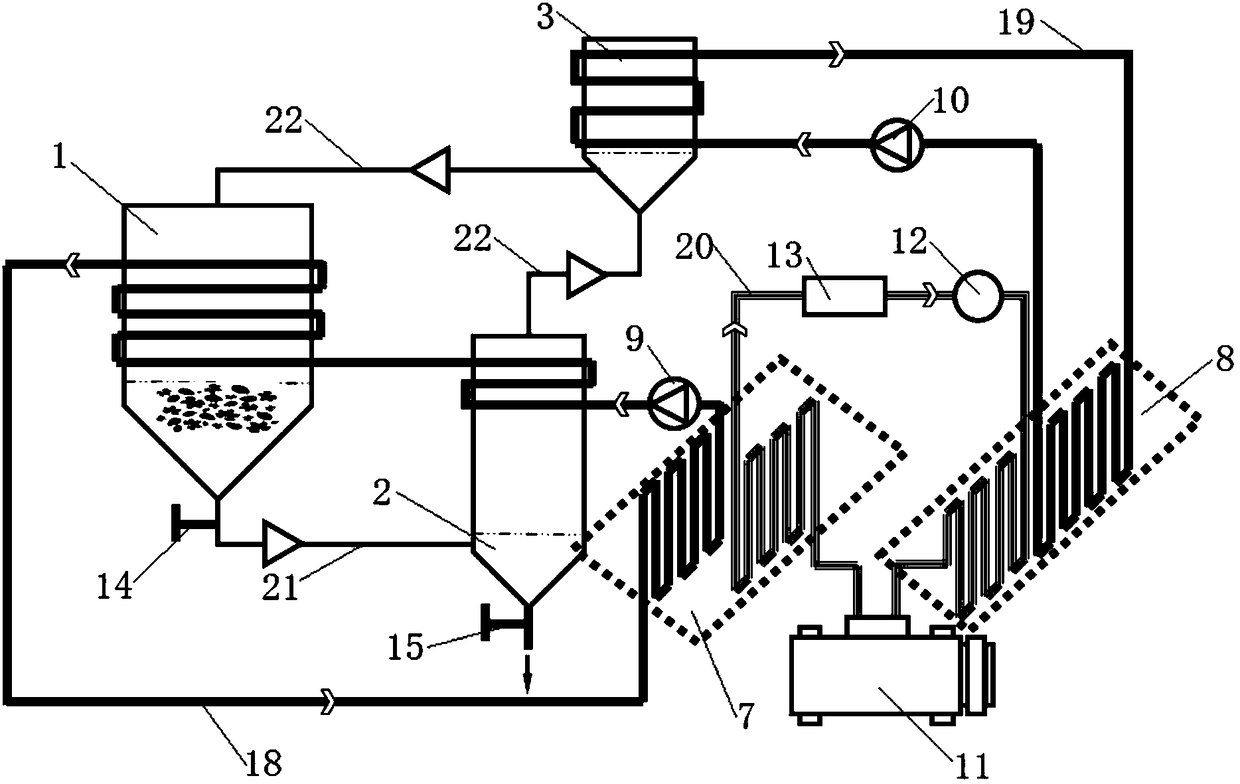

[0035] An air energy plant active substance extraction system, such as figure 2As shown, it includes an extraction tank 1, a vacuum concentrator 2, a condenser 3, a first heat exchanger 7, a second heat exchanger 8 and a refrigerant circuit. The extraction tank 1 is used to mix plants and solvents and extract plant actives The vacuum concentrator 2 is connected with the extraction tank 1 for concentrating the extracted plant actives, and the solvent is separated; the condenser 3 is connected with the vacuum concentrator 2 and the extraction tank 1 at the same time, and the solvent from the vacuum concentrator 2 is carried out Condensed and supplied to the extraction tank 1; the first heat exchanger 7 includes a heating water pipe 18 and a refrigerant heat exchange pipe for mutual heat exchange, and the heating water pipe 18 communicates with the interlayer or heat exchange coil of the extraction tank 1 and the vacuum concentrator 2 at the same time , supplying heat to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com