A tvs-2m grid cell and coaming welding electrode clamping device

A TVS-2M, welding electrode technology, applied in auxiliary devices, electrode features, welding equipment, etc., can solve the problems of product repair, restricting production efficiency, unstable electrode chuck clamping force, etc., to achieve stable clamping pressure, Guaranteed welding quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

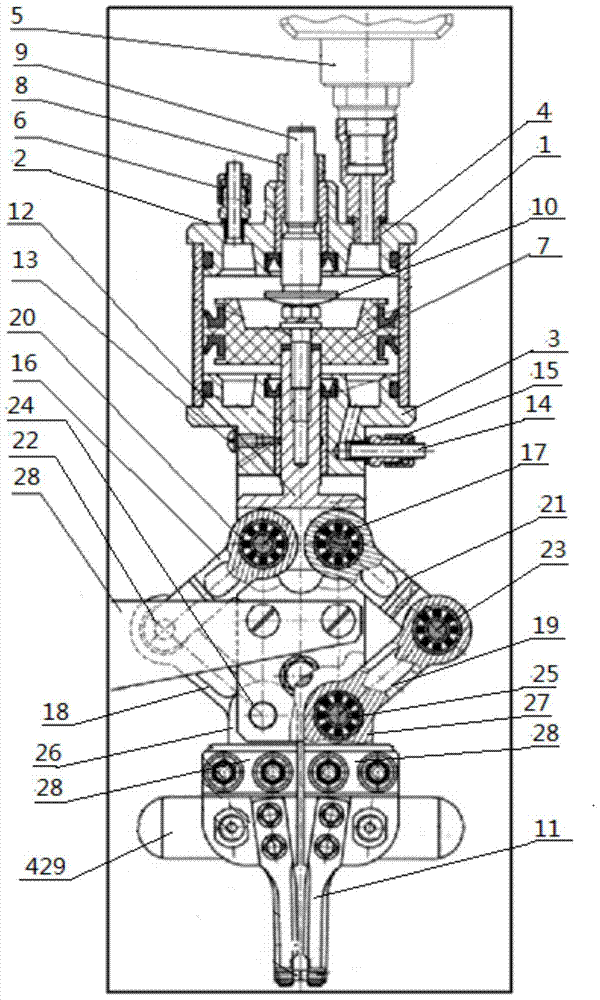

[0017] The TVS-2M grid cell and shroud welding electrode clamping device of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] like figure 1 As shown, the TVS-2M grid cell and coaming welding electrode clamping device of the present invention has a cylinder 1, the cylinder 1 is cylindrical and hollow inside, and the upper and lower ends pass through the upper sealing cover 2 and the lower sealing cover 3 sealed. The upper sealing cover 2 is provided with a pressure measuring port 4 communicating with the inside of the cylinder 1 , and the pressure measuring port 4 is connected to the air pressure sensor through a connector 5 . The upper sealing cover 2 is also provided with an air inlet 6 for the entry and discharge of air. The middle part of the upper sealing cover 2 is also provided with a through hole, and a nut 8 is sealed and installed in the hole, and a movable screw mandrel 9 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com