A multifunctional end effector for automatic drilling and riveting machine

A technology of end effector and automatic drilling and riveting machine, which is applied in the direction of manipulators, other manufacturing equipment/tools, manufacturing tools, etc., and can solve the problems of enlarged end effector, low degree of unit integration, and decreased riveting quality. Achieve the effect of realizing intelligent detection, ensuring accessibility and efficiency, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

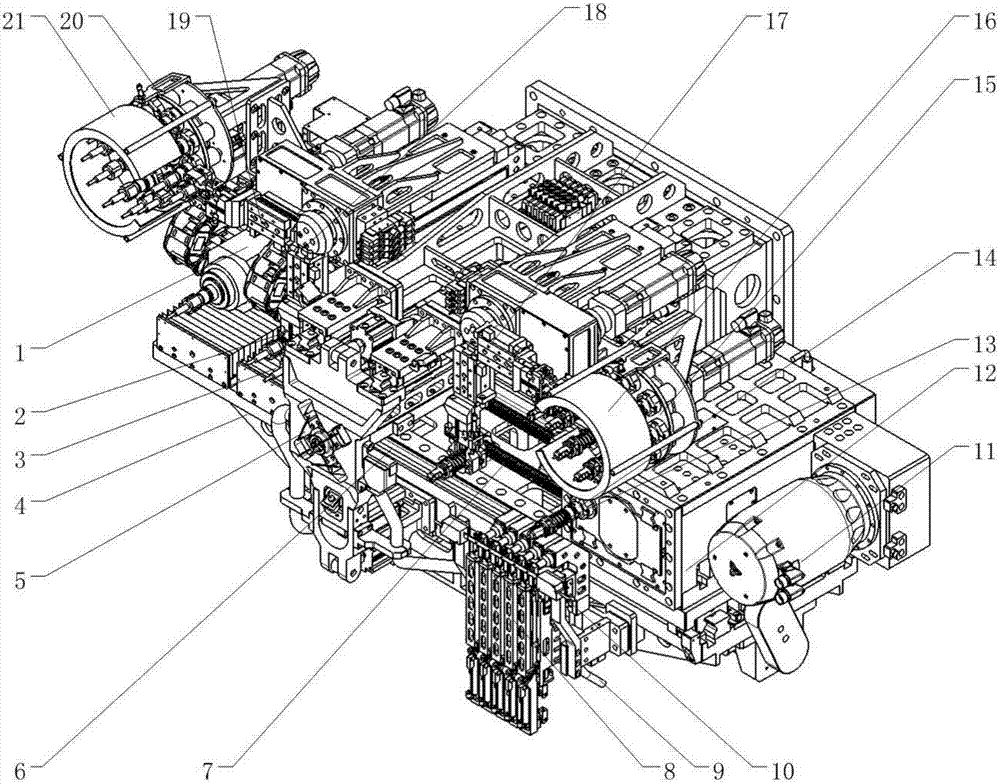

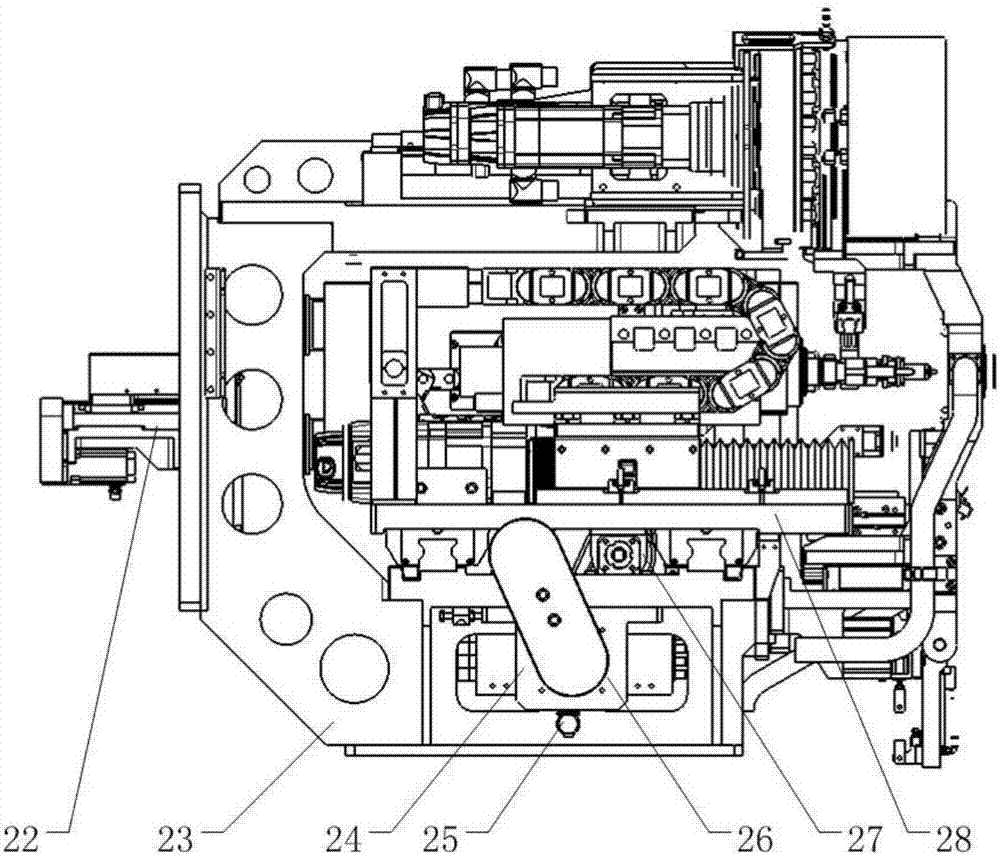

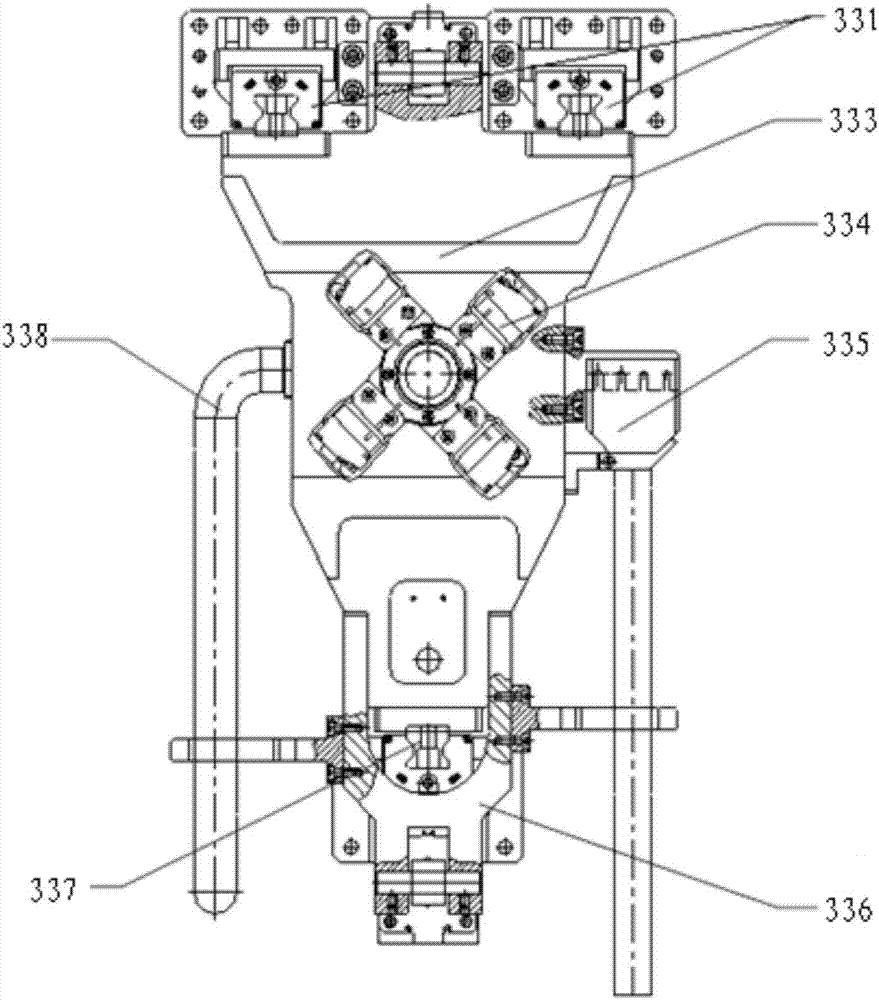

[0058] As shown in Figure 1(a) and Figure 1(b), a multifunctional end effector for automatic drilling and riveting machines includes a hole making unit 1, a milling unit 2, a hole measuring unit 3, a base unit 4, Presser foot unit 5 , nail feeding unit 8 , nail insertion unit 12 , tool changing unit 18 and visual measurement unit 22 .

[0059] The base unit 4 includes an actuator base 23 and a station switch drive assembly 24 installed on the actuator base 23, and the visual measurement unit 22 is fixedly installed on the back of the actuator base 23; the station switch drive assembly 24 includes a servo motor 25, synchronous belt 26, leading screw nut seat 27 and station slide plate 28. The visual measurement unit 22 is fixedly installed on the back of the actuator base 23 . The nail insertion unit 12 is mainly composed of a driving motor assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com