Defoaming device of single-component liquid resin and defoaming method

A liquid resin, single-component technology, applied in the field of degassing devices for single-component liquid resin, can solve the problems of high viscosity of resin mixture, unguaranteed quality, short operating time, etc., to achieve improved defoaming rate, Cleaning is completely economical and the effect of improving the defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

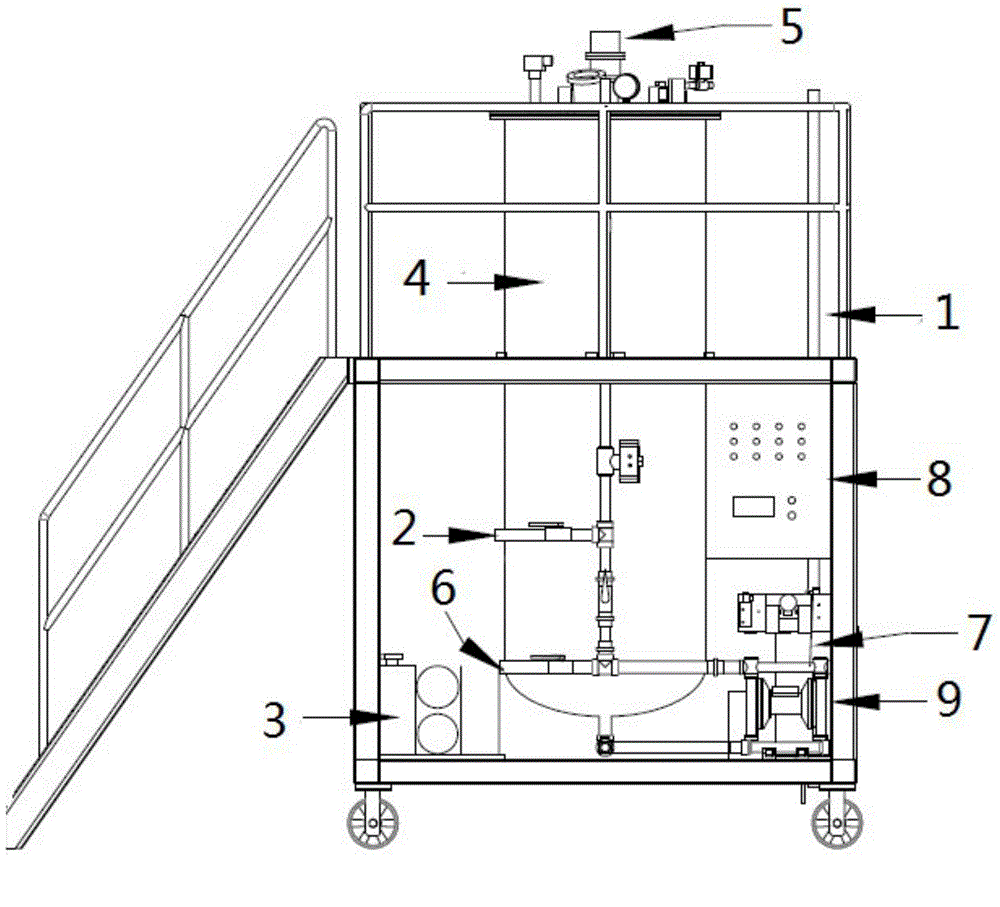

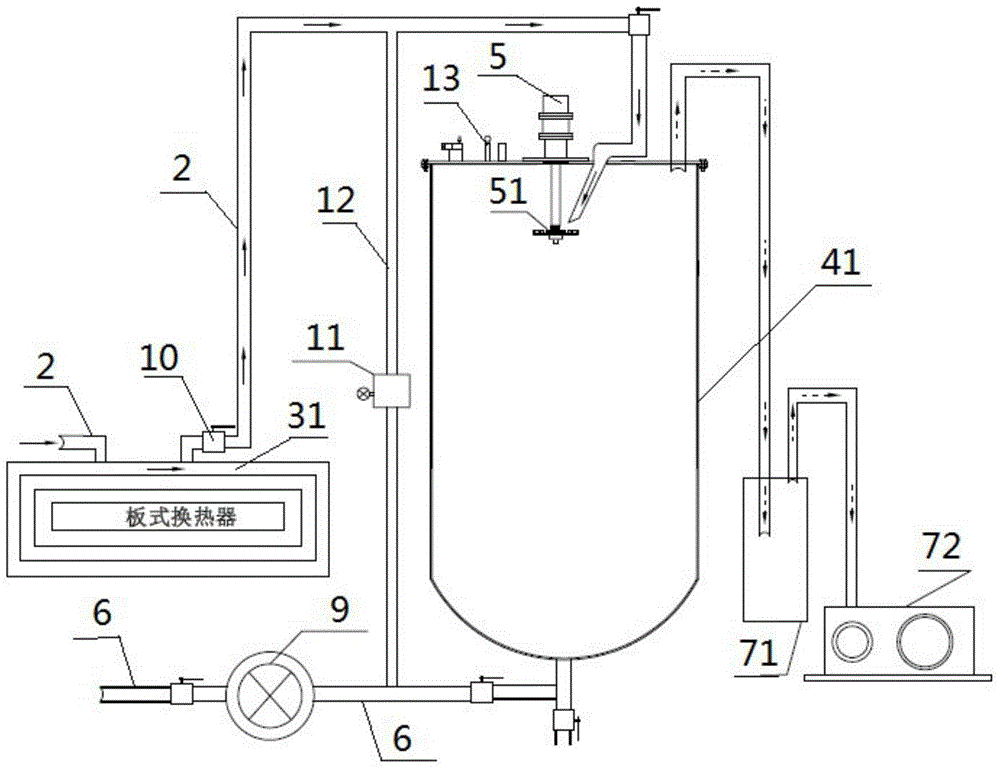

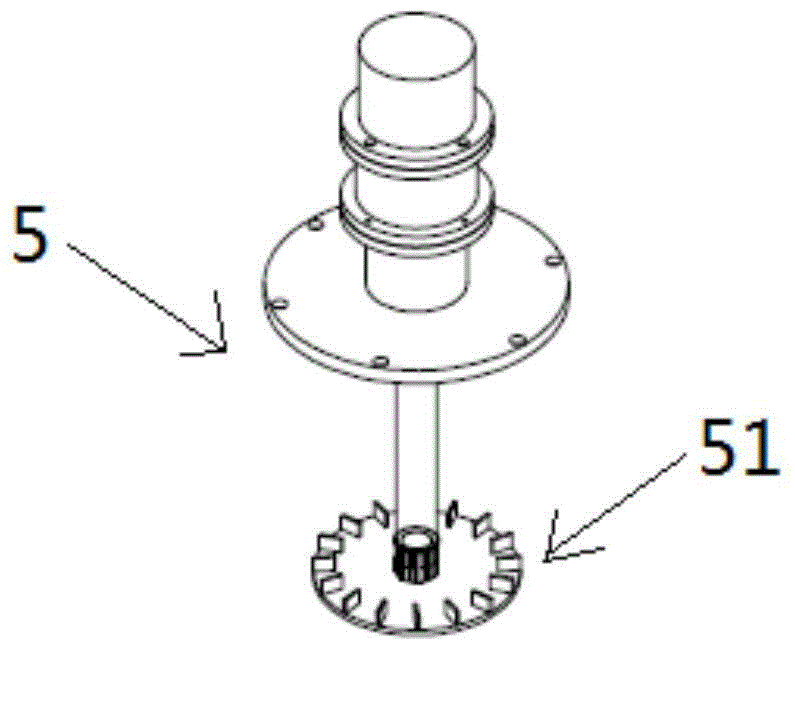

[0032] combine figure 1 , figure 2 , the defoaming device of the single-component liquid resin in the present embodiment is installed on the frame 1 as a whole, including the feed channel 2; the heating system 3, which can be a common PTC heating system with a heating flow channel 31 Devices, plate heat exchangers heated by fluid medium, etc.; defoaming device 4, the defoaming device 4 is equipped with a rotary distributor 5; vacuum system 7; discharge channel 6; control system 8; diaphragm pump 9, etc. The feed channel 2 is connected to the heating flow channel 31 of the heating system 3, the heating flow channel 31 of the heating system 3 is connected to the defoaming device 4, and the defoaming device 4 is connected to the discharge channel 6, and the vacuum system 7 is a defoaming device 4 Provide a vacuum environment. The return pipeline 12 communicates with the discharge channel 6 and the feed channel 2 , and under normal circumstances the return valve 11 is closed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com