Method for drawing color lines on plate-type ceramic product to form concave-convex embossment pattern

A ceramic product and embossing technology, which is applied in the crafting and decorative arts for producing decorative surface effects, can solve the problems of thick pad printing lines, no layering, dull glaze color, etc., and achieve the coordination of patterns and glaze layers and the operation steps Simple, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

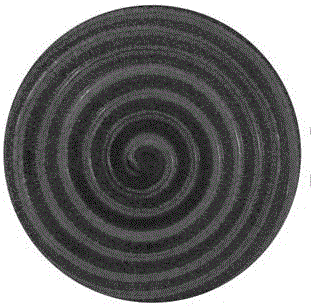

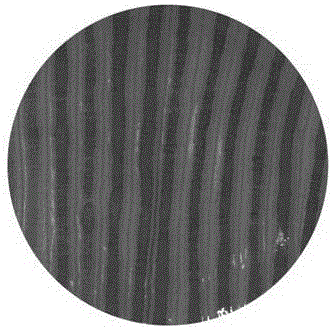

Image

Examples

Embodiment Construction

[0020] This embodiment takes daily-use ceramic disc products as an example. It is a method for drawing color lines on disc ceramic products to form concave-convex relief patterns. It is dried and sent to a kiln for firing. It is characterized in that the above-mentioned method is a combination of glazing and needle drawing to form a concave-convex relief pattern, that is, kiln-changing glaze is used as the bottom glaze and a strong flux is used for cleaning. Ear balls and needles are formed by drawing lines and circles. The specific steps are as follows: A. Firstly, after washing the green body, bisque firing is carried out. The biscuit firing temperature is 500-600°C, and the bisque firing time is 4-5 hours;

[0021] B. Prepare the designed artwork, and prepare the corresponding colors according to the artwork. At the same time, prepare the body for glaze operation, measure the corresponding concentration for the glaze that needs to be glazed, and pass through a 200-mesh sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com