Energy feedback method and system for hybrid electric vehicle

A technology of hybrid electric vehicles and braking energy feedback, which is applied in hybrid electric vehicles, electric braking systems, motor vehicles, etc., can solve the problems of low efficiency of braking energy feedback, improve fuel economy and increase braking energy Feedback efficiency and the effect of extending battery driving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

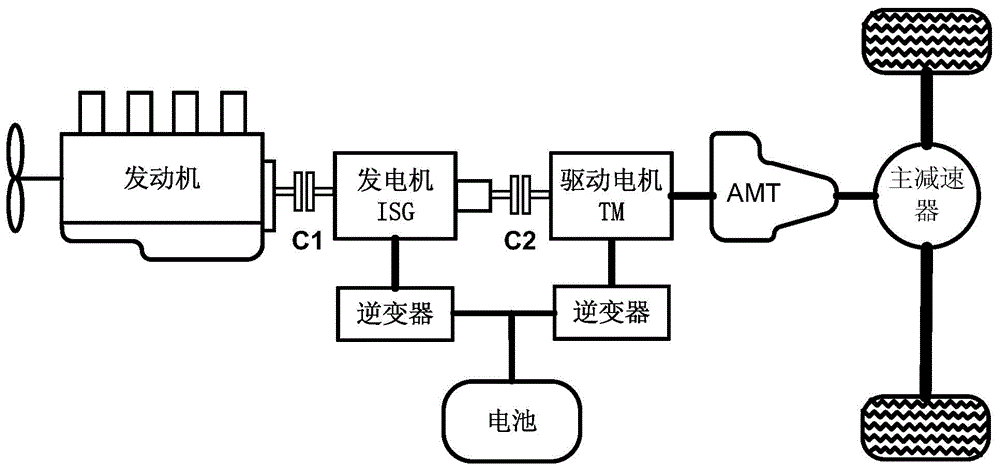

[0063] In this embodiment, the deep hybrid system structure of the hybrid vehicle is as follows figure 2 shown. The engine back is connected with the clutch C1 driving disk, the clutch C1 driven disk is connected with the generator, the clutch C2 driving disk is connected with the generator back, and the clutch C2 driven disk is connected with the drive motor. The power battery is connected with the generator controller and the drive motor controller. The drive motor is followed by an electromechanical automatic transmission (AMT transmission), and the final drive is connected with the AMT transmission through a transmission shaft. The AMT transmission controller (TCU) controls the clutch and the gear selection mechanism to perform the gear selection operation.

[0064] The hybrid system can realize multiple working modes: when the clutch C1 is disengaged, the power battery supplies power to the drive motor (TM) and / or generator (ISG) to drive the vehicle, and this structure...

Embodiment 2

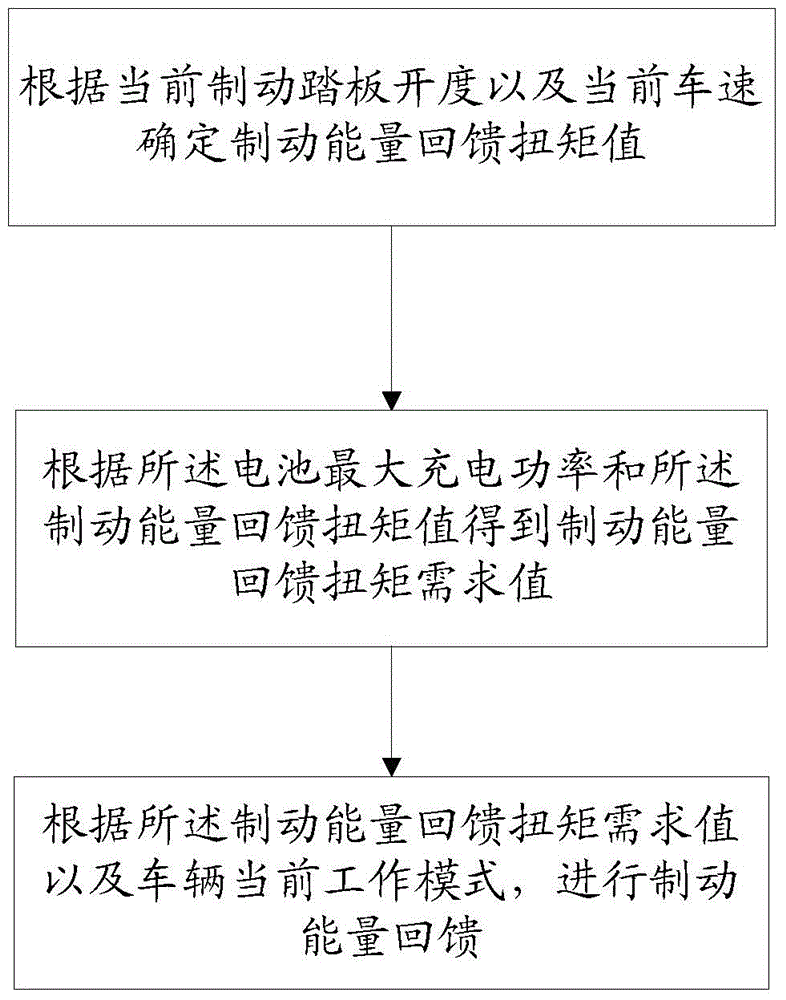

[0067] In this embodiment, an energy feedback method for a hybrid electric vehicle is provided, and the flow chart is as follows image 3 shown, including the following steps:

[0068] The first step is to obtain the current brake pedal opening value and the current vehicle speed, and determine the braking energy feedback torque value according to the current brake pedal opening degree and the current vehicle speed.

[0069] When the vehicle is running, the current recoverable energy value can be obtained through the current speed and the opening value of the brake pedal. The opening value of the brake pedal here can be 0-100%. When the opening value is 0, it means that the vehicle has not stepped on the brake pedal. At this time, it is in a coasting state. When the opening value of the brake pedal is greater than 0 , indicating that the brake pedal is applied, and the braking force is proportional to the opening of the brake pedal. When the opening of the brake pedal is 100%...

Embodiment 3

[0080] This embodiment provides an energy feedback method for a hybrid electric vehicle. The first step and the second step of the method are the same as the first step and the second step in Embodiment 1. Two working modes are explained separately.

[0081] Since the current working mode of the hybrid vehicle includes pure electric working mode, series mode, and parallel mode, when the clutch between the engine and the generator is separated and the power battery supplies power to the drive motor and / or generator to drive the vehicle, the structure is Pure electric mode; when the clutch between the engine and the generator is closed, the clutch between the generator and the drive motor is separated, the engine charges the power battery through the generator, and the power battery provides power for the drive motor at the same time to drive the vehicle. It is a series mode; when the clutch between the engine and the generator is closed, and at the same time the clutch between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com