Use method of constant-temperature water glass container

A glass container and constant temperature water technology, applied in the field of kitchen utensils, can solve the problems of not being able to understand the water temperature, inconvenience of drinking hot water, scalding the mouth, etc., and achieve the effects of avoiding scalding lips, high flexibility, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

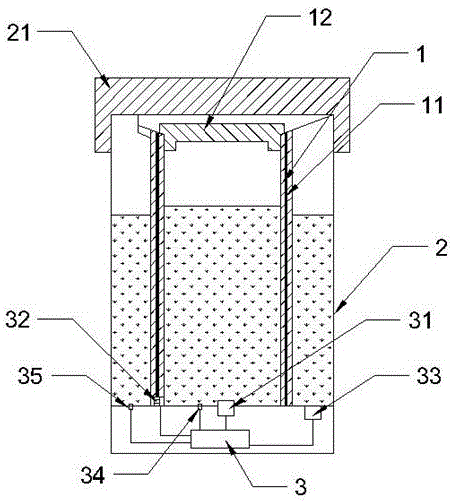

[0019] The reference signs in the accompanying drawings of the description include: inner cup 1, airgel felt 11, inner cover 12, outer vessel 2, container cover 21, control center 3, condenser 31, temperature control valve 32, heater 33, second A temperature sensor 34 and a second temperature sensor 35 .

[0020] The constant temperature water glass container in this program includes an inner cup 1 and an outer vessel 2 from the inside to the outside. There is a gap between the inner cup 1 and the outer vessel 2 to form an outer cavity. The inner cup 1 is covered with an inner cup with a through hole. Cover 12, a temperature control valve 32 connecting the inner cup and the outer cavity is installed in the lower wall of the inner cup 1, a first temperature sensor 34 and a condenser 31 are installed at the bottom of the inner cup 1, and a temperature control valve 32 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com