Stopper rod for controlling liquid-state molten slag flow

A liquid slag and flow technology, which is applied in the field of blast furnace slag waste heat recovery, can solve the problems of plug rods that are not resistant to high temperature slag erosion, short service life, easy to break, etc., and achieves good thermal shock resistance, prevents slag corrosion, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

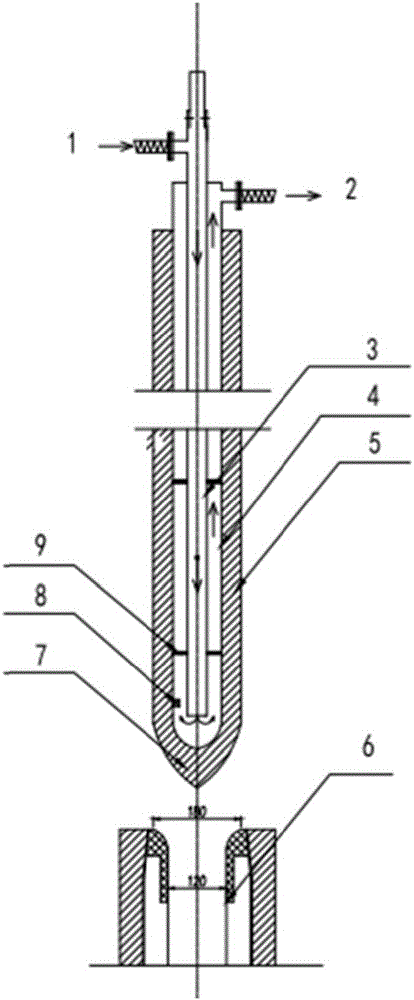

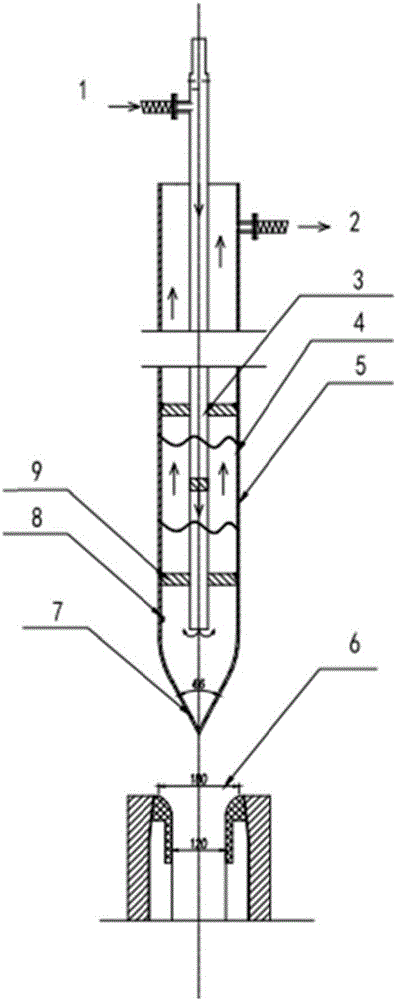

[0026] Such as figure 1 As shown, a stopper rod for controlling the flow of liquid slag includes a metal inner tube 3 , a metal outer tube 4 , a heat insulation layer 5 , a cold air inlet 1 and a hot air outlet 2 .

[0027] The metal inner tube 3 is sleeved in the middle of the metal outer tube 4 to form a hollow arrangement. The metal outer tube 4 and the metal inner tube 3 are fixed by connecting ribs 9, and the metal outer tube 4 is provided with pull hooks and pins, and the refractory material is laid on the surface of the metal outer tube.

[0028] The lower port of the metal inner tube 3 communicates with the metal outer tube 4, the lower end of the metal outer tube 4 is sealed, and the upper end is provided with a hot air outlet 2; the upper part of the metal inner tube 3 is provided with a cold air inlet 1. The cold wind enters the metal inner tube 3 from the cold wind inlet 1, and enters the metal outer tube 4 from the bottom of the metal inner tube 3 for heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com